Small scale continuous production system of cyclohexanone oxime

A technology of cyclohexanone oxime and production equipment, which is applied in oxime preparation, organic chemistry, etc., and can solve problems such as over-temperature danger, over-pressure danger, and inability to adapt to new process requirements.

- Summary

- Abstract

- Description

- Claims

- Application Information

AI Technical Summary

Problems solved by technology

Method used

Image

Examples

Embodiment Construction

[0029] The present invention will be described in detail below in conjunction with specific embodiments.

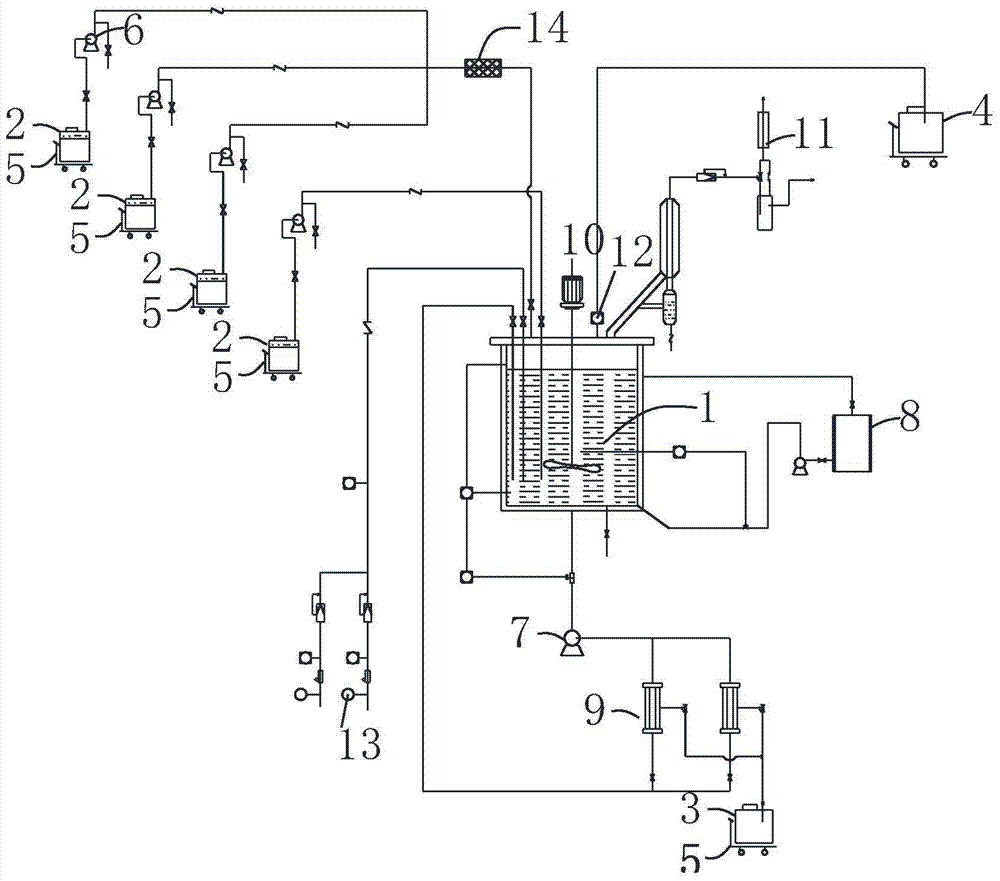

[0030] The present invention, a kind of small-scale continuous production system of cyclohexanone oxime, such as figure 1 As shown, it includes a reactor 1, a feed system, a discharge system, a heat supply system 8, a condensation system and a gas supply system 13, wherein the heat supply system uses oil bath heating to supply heat to the reactor, and the condensation system uses To condense the evaporated solvent such as tert-butanol and make it return to the inside of reactor 1, the condensing system can be a straight condenser tube and a serpentine condenser tube that are routinely selected in the laboratory, and a gas sampling tube is connected above the condenser tube Road 11, the gas supply system delivers gas to the reactor 1, so that the reactor reaches the pressure value required for the reaction, and a pressure reducing valve is installed on the pipeline connect...

PUM

Login to View More

Login to View More Abstract

Description

Claims

Application Information

Login to View More

Login to View More - R&D

- Intellectual Property

- Life Sciences

- Materials

- Tech Scout

- Unparalleled Data Quality

- Higher Quality Content

- 60% Fewer Hallucinations

Browse by: Latest US Patents, China's latest patents, Technical Efficacy Thesaurus, Application Domain, Technology Topic, Popular Technical Reports.

© 2025 PatSnap. All rights reserved.Legal|Privacy policy|Modern Slavery Act Transparency Statement|Sitemap|About US| Contact US: help@patsnap.com