Linseed oil debittering and deodorization treatment method

A technology of linseed oil and linseed meal, which is applied in the fields of edible oil/fat, fat oil/fat refining, fat production, etc.

- Summary

- Abstract

- Description

- Claims

- Application Information

AI Technical Summary

Problems solved by technology

Method used

Image

Examples

Embodiment 1

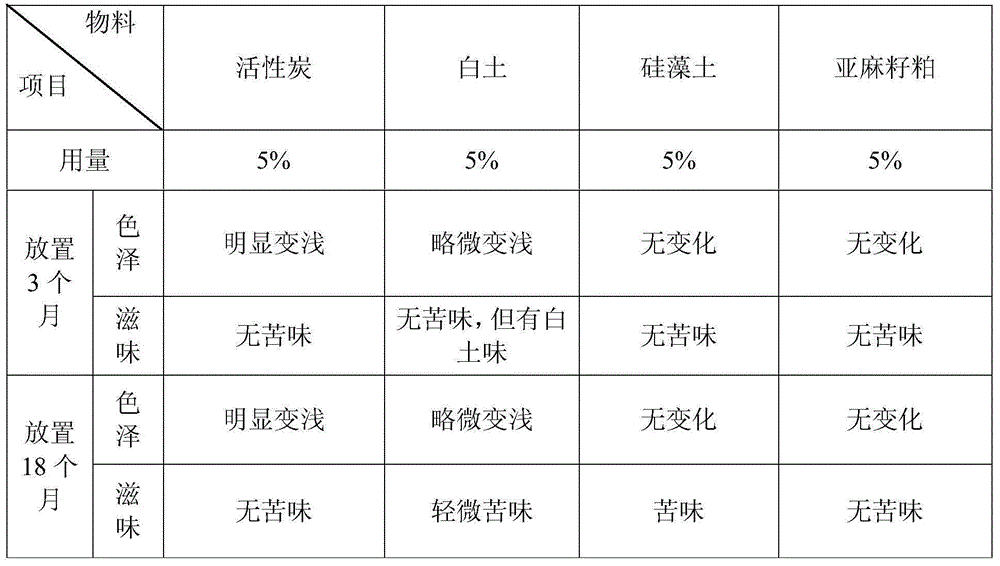

[0029] Example 1 Screening experiment of debittering and deodorizing materials

[0030] Follow the steps below to screen linseed oil for debittering and deodorizing materials:

[0031] 1. Prepare the initial product of linseed oil

[0032] Preliminary product of linseed oil is prepared based on cold pressing method, specific method:

[0033] The linseed is passed through a 40-mesh vibrating sieve to remove fine impurities, and then a 2.0 kW stone-removing specific gravity machine is used to further remove larger and heavier impurities, and the linseed kernels are obtained by dehulling with a sheller, and sent to a cold-pressing press, into The pressing temperature is controlled at about 20°C, and the pressing chamber temperature of the press is controlled at 50±5°C, so as to obtain shelled linseed meal powder (oil content <1%, water content less than 0.5%) and cold-pressed crude product respectively.

[0034] Next, add 5% by mass of water at a temperature of 75°C to the cold...

Embodiment 2

[0043] Example 2 Optimization Test of Linseed Meal Addition

[0044]Follow the steps below to determine the optimum amount of linseed meal for debittering and deodorizing treatment of linseed oil:

[0045] 1. Prepare the initial product of linseed oil

[0046] With reference to the method in Example 1, the initial product of linseed oil was prepared.

[0047] 2. Remove bitterness and smell

[0048] Ten treatments were set up in this test, and each treatment was added to the initial product of linseed oil at a temperature of 2° C., adding shelled linseed meal powder of the quality shown in Table 2 below (oil content < 1%, moisture content less than 0.5%) ) and 2% by mass of diatomaceous earth, so that the dehulled linseed meal powder and diatomite can fully absorb the bitterness and fishy smell of linseed oil, so as to carry out debittering and deodorizing treatment.

[0049] Next, pump the absorbed linseed oil into a filter with a screw pump, and filter and remove diatomite...

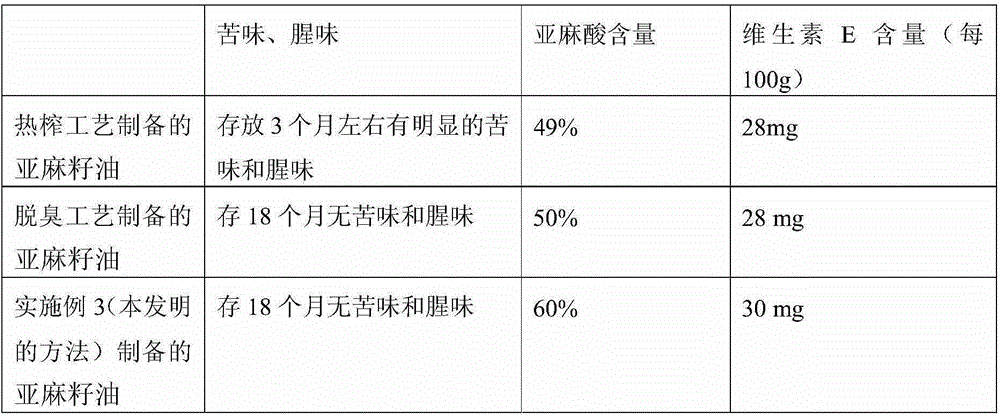

Embodiment 3

[0056] According to the treatment method for debittering and deodorizing linseed oil of the present invention, linseed oil is prepared, specifically as follows:

[0057] First, referring to the method in Example 1, a primary product of linseed oil at a temperature of 2° C. was prepared.

[0058] Next, add 5 mass % dehulled linseed meal powder (oil content < 1%, water content less than 0.5%) and 2 mass % diatomaceous earth to the initial product of linseed oil at 2 ° C, stir for 4 hours, The husked linseed meal powder and diatomaceous earth are used to fully absorb the bitterness and fishy smell of the linseed oil, so as to perform debittering and deodorizing treatment.

[0059] Then, use a screw pump to pump the absorbed linseed oil into the filter, filter and remove diatomaceous earth and linseed meal powder under a pressure of ≤0.4Mpa, and remove the wax in the oil through diatomite adsorption at the same time, In order to obtain debitter and deodorized linseed oil.

PUM

Login to View More

Login to View More Abstract

Description

Claims

Application Information

Login to View More

Login to View More - R&D

- Intellectual Property

- Life Sciences

- Materials

- Tech Scout

- Unparalleled Data Quality

- Higher Quality Content

- 60% Fewer Hallucinations

Browse by: Latest US Patents, China's latest patents, Technical Efficacy Thesaurus, Application Domain, Technology Topic, Popular Technical Reports.

© 2025 PatSnap. All rights reserved.Legal|Privacy policy|Modern Slavery Act Transparency Statement|Sitemap|About US| Contact US: help@patsnap.com