Preparation method of nano-particle material

A technology of nanoparticle and preparation method, which is applied in the field of preparation of nanoparticle materials and can solve problems such as environmental pollution

- Summary

- Abstract

- Description

- Claims

- Application Information

AI Technical Summary

Problems solved by technology

Method used

Image

Examples

Embodiment 1

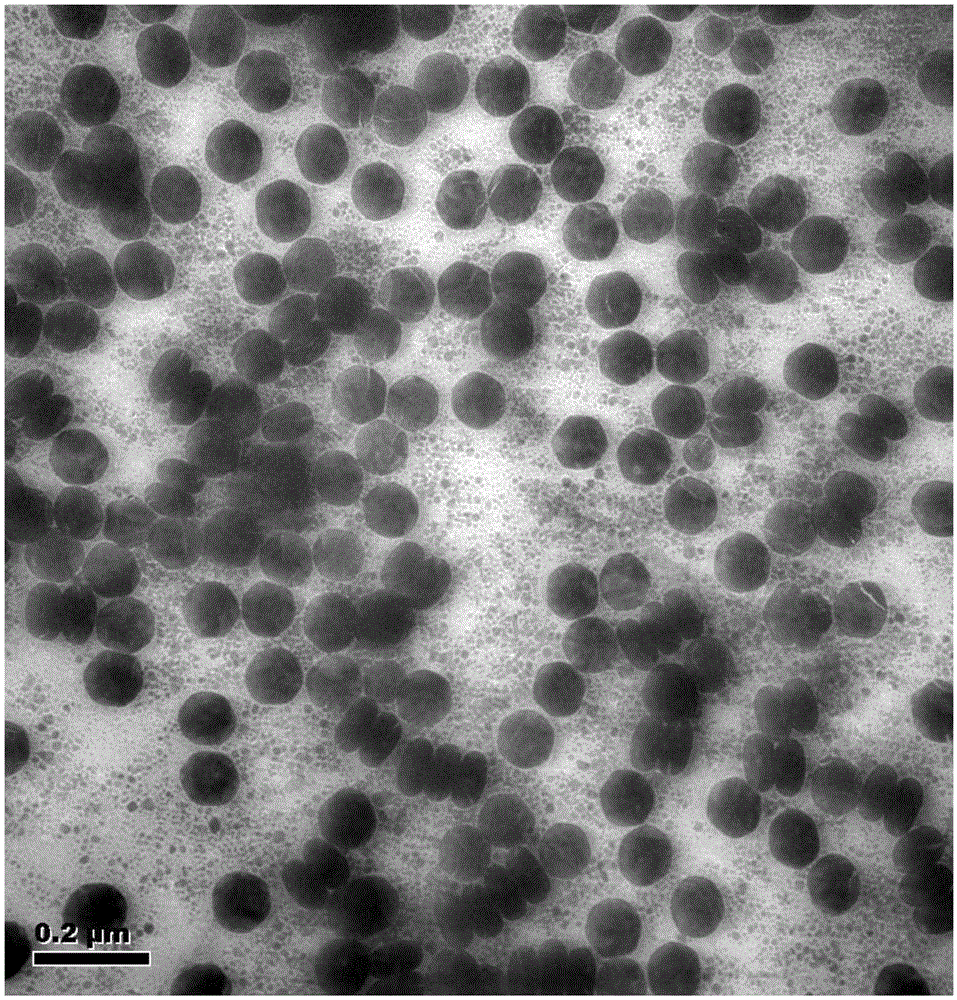

[0025] Embodiment 1 silver nanoparticles

[0026] Weigh 10g of peptone, 5g of yeast and 10g of sodium chloride and dissolve in 1L of deionized water to adjust the pH to about 7. Stored after high temperature and high pressure sterilization. Inoculate the strain Pantoea agglomerans IMH into the obtained 100 mL medium solution with an inoculation loop. Afterwards, the solution was placed in a shaker and cultured with shaking at 30° C. and 150 rpm for 12 hours. Subsequently, 1 mL of the activated bacterial solution was drawn and transferred to 100 mL of sterilized medium, and the solution was placed in a shaker again, and cultured with shaking at 30° C. and 150 rpm for 12 h. Take 50mL logarithmic phase bacteria solution in a centrifuge tube and centrifuge at 8000rpm for 5 minutes. When finished, remove the supernatant and collect the cells at the bottom of the tube. The collected cells were dispersed into 50 mL of sterilized LB medium without NaCl. Add a certain amount of si...

Embodiment 2

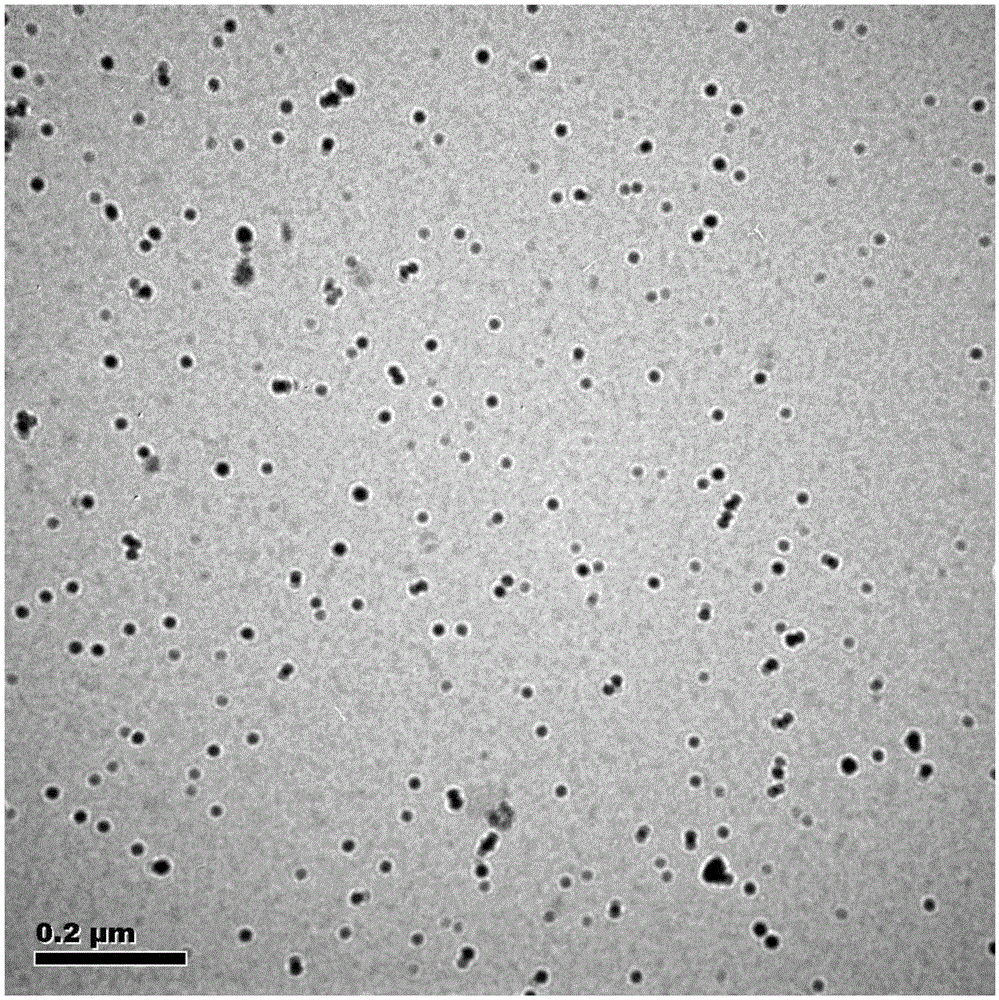

[0027] Embodiment 2 gold nanoparticles

[0028] Weigh 10g of peptone, 5g of yeast and 10g of sodium chloride and dissolve in 1L of deionized water to adjust the pH to about 7. Stored after high temperature and high pressure sterilization. Inoculate the strain Pantoea agglomerans IMH into the obtained 100 mL medium solution with an inoculation loop. Afterwards, the solution was placed in a shaker and cultured with shaking at 30° C. and 150 rpm for 12 hours. Subsequently, 1 mL of the activated bacterial solution was drawn and transferred to 100 mL of sterilized medium, and the solution was placed in a shaker again, and cultured with shaking at 30° C. and 150 rpm for 12 h. Take 50mL logarithmic phase bacteria solution in a centrifuge tube and centrifuge at 8000rpm for 5 minutes. When finished, remove the supernatant and collect the cells at the bottom of the tube. The collected cells were dispersed into 50 mL of sterilized PBS buffer. Add a certain amount of chloroauric acid...

Embodiment 3

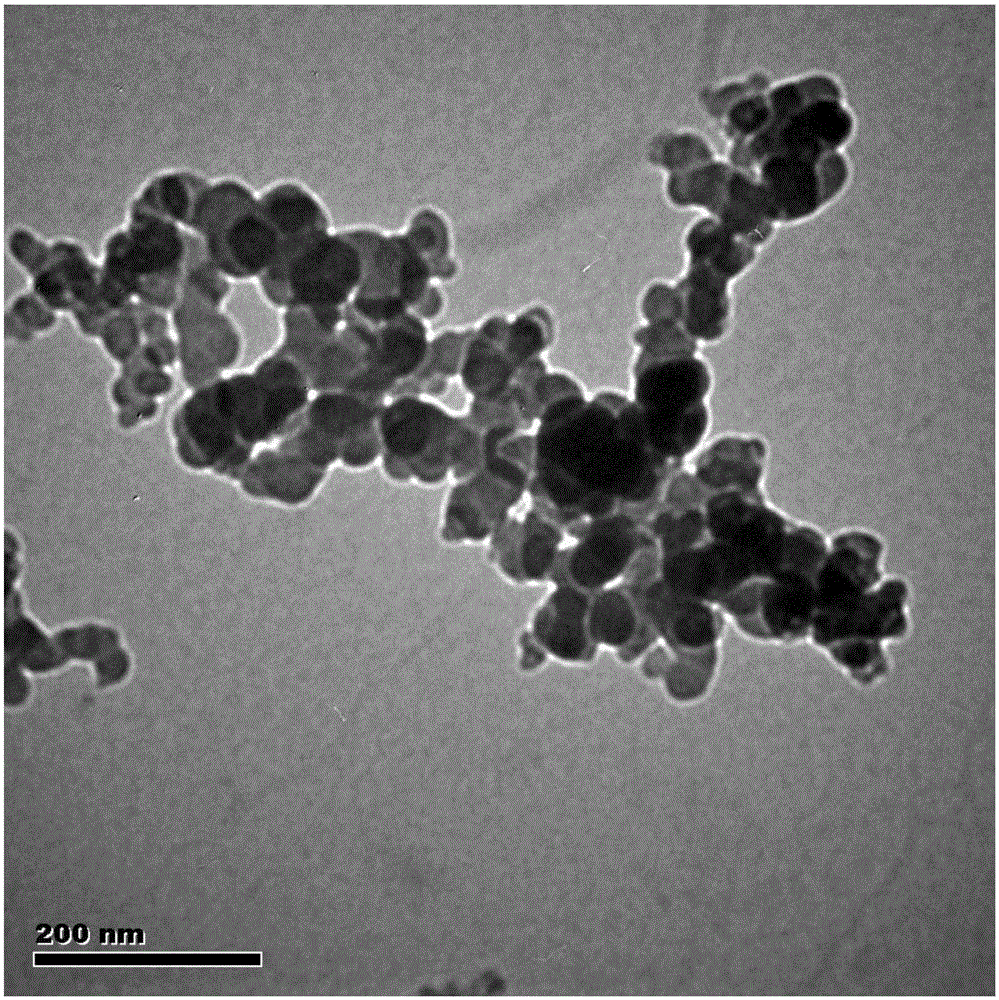

[0029] Embodiment 3 palladium nanoparticles

[0030] Weigh 10g of peptone, 5g of yeast and 10g of sodium chloride and dissolve in 1L of deionized water to adjust the pH to about 7. Stored after high temperature and high pressure sterilization. Inoculate the strain Pantoea agglomerans IMH into the obtained 100 mL medium solution with an inoculation loop. Afterwards, the solution was placed in a shaker and cultured with shaking at 30° C. and 150 rpm for 12 hours. Subsequently, 1 mL of the activated bacterial solution was drawn and transferred to 100 mL of sterilized medium, and the solution was placed in a shaker again, and cultured with shaking at 30° C. and 150 rpm for 12 h. Take 50mL logarithmic phase bacteria solution in a centrifuge tube and centrifuge at 8000rpm for 5 minutes. When finished, remove the supernatant and collect the cells at the bottom of the tube. The collected cells were dispersed into 50 mL of sterilized PBS buffer. A certain amount of palladium nitra...

PUM

| Property | Measurement | Unit |

|---|---|---|

| particle diameter | aaaaa | aaaaa |

| particle diameter | aaaaa | aaaaa |

| particle diameter | aaaaa | aaaaa |

Abstract

Description

Claims

Application Information

Login to View More

Login to View More - R&D

- Intellectual Property

- Life Sciences

- Materials

- Tech Scout

- Unparalleled Data Quality

- Higher Quality Content

- 60% Fewer Hallucinations

Browse by: Latest US Patents, China's latest patents, Technical Efficacy Thesaurus, Application Domain, Technology Topic, Popular Technical Reports.

© 2025 PatSnap. All rights reserved.Legal|Privacy policy|Modern Slavery Act Transparency Statement|Sitemap|About US| Contact US: help@patsnap.com