Blast furnace mud gun mud volume display device

A technology for displaying the amount of sludge, which is applied to blast furnaces, details of blast furnaces, and parts of blast furnaces. It can solve problems such as the inability to accurately measure the amount of sludge produced by blast furnace mud cannons, and achieve stable sludge volume, cost reduction, and blindness reduction. The effect of homework

- Summary

- Abstract

- Description

- Claims

- Application Information

AI Technical Summary

Problems solved by technology

Method used

Image

Examples

Embodiment 1

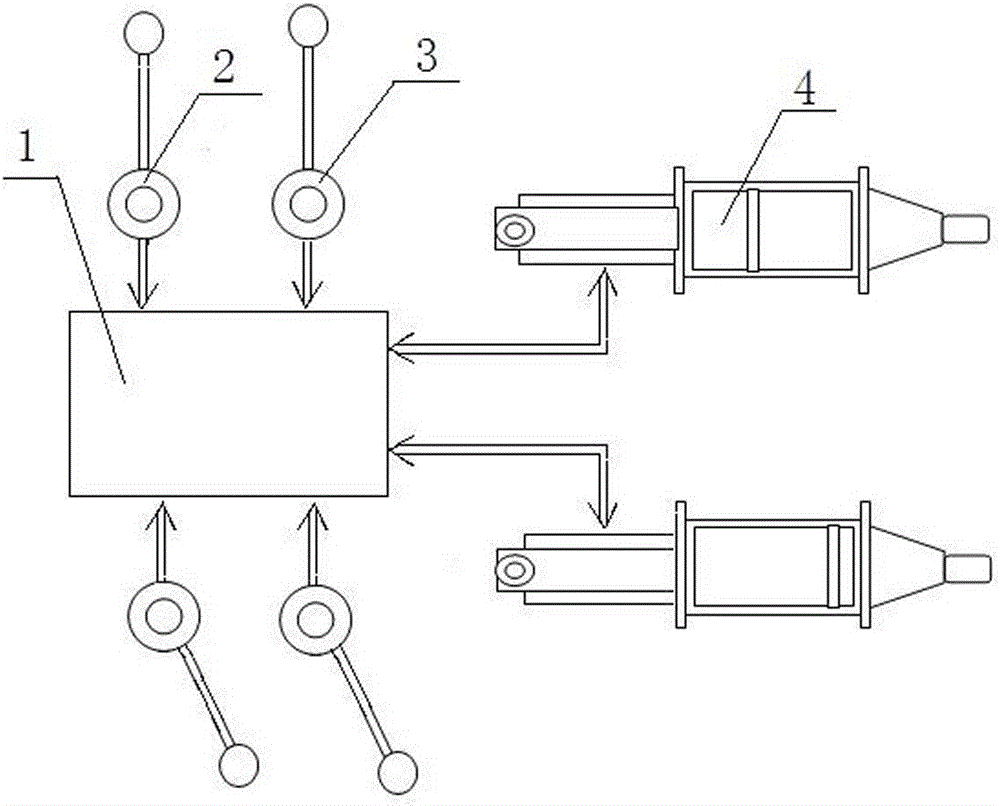

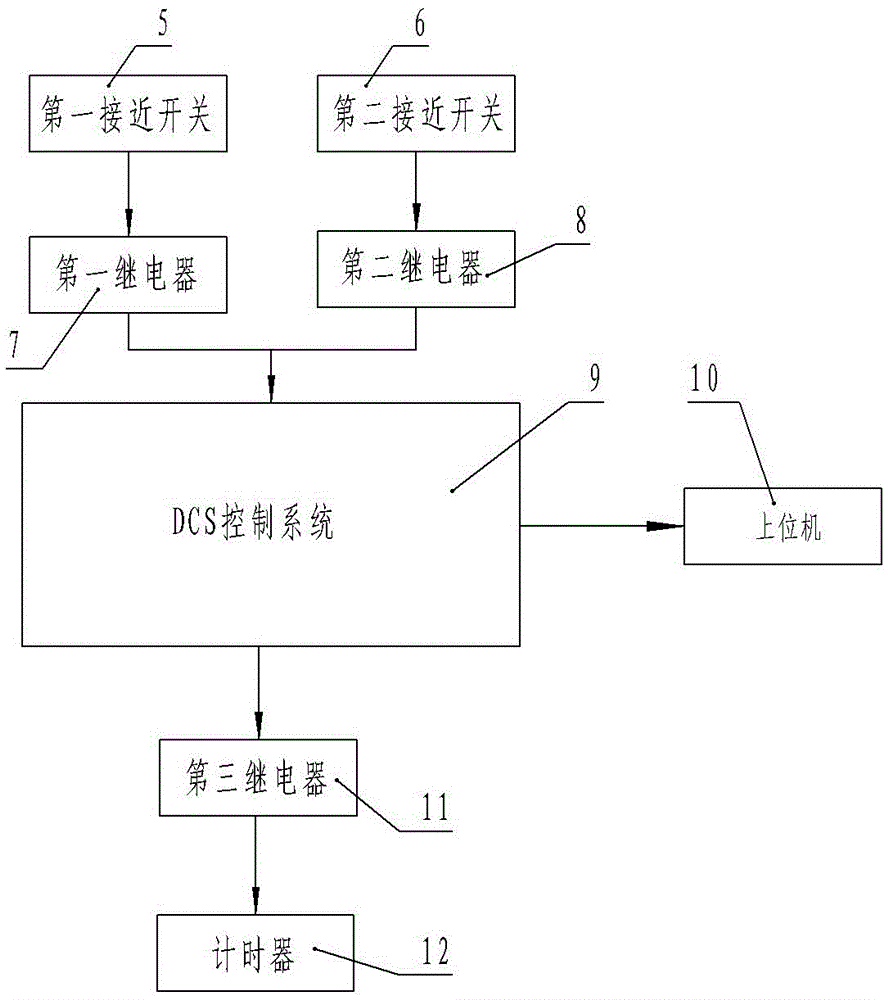

[0019] figure 2 The blast furnace mud cannon shown in the display device includes a first proximity switch 5 arranged at the operating handle 2 of the rotary gun and a second proximity switch 6 arranged at the operating handle 3 of the mud beating. The first proximity switch 5 The first relay 7 is connected to the corresponding signal input end of the DCS control system 9, the second proximity switch 6 is connected to the corresponding signal input end of the DCS control system through the second relay 8, and the signal output end of the DCS control system 9 is passed through the second relay 8. The three relays 11 are connected to the signal input terminals of the timer 12. The DCS control system has an Ethernet module, and the Ethernet module is connected to the upper computer 10 through a network cable;

[0020] Wherein: when the rotary cannon operating handle 2 is turned to the working position, the predetermined distance between the rotary cannon operating handle 2 and t...

Embodiment 2

[0022] When the electric signal output by the first proximity switch 5 lasts for 35 seconds after induction, it is judged to be the signal of the rotating gun, and the rest are the same as in the first embodiment.

Embodiment 3

[0024] When the electric signal output by the first proximity switch 5 lasts for 50 seconds after sensing, it is judged to be the signal of the rotating gun, and the rest are the same as in the first embodiment.

PUM

Login to View More

Login to View More Abstract

Description

Claims

Application Information

Login to View More

Login to View More - R&D

- Intellectual Property

- Life Sciences

- Materials

- Tech Scout

- Unparalleled Data Quality

- Higher Quality Content

- 60% Fewer Hallucinations

Browse by: Latest US Patents, China's latest patents, Technical Efficacy Thesaurus, Application Domain, Technology Topic, Popular Technical Reports.

© 2025 PatSnap. All rights reserved.Legal|Privacy policy|Modern Slavery Act Transparency Statement|Sitemap|About US| Contact US: help@patsnap.com