Novel assembly type field culvert building

An assembled and building technology, applied in the direction of construction, road bottom, soil drainage, etc., can solve the problems of not considering relevant relationships, fixed type and specification, prefabrication and construction inconvenience, etc., to achieve simplification of design, high speed, The effect of improving quality and installation level

- Summary

- Abstract

- Description

- Claims

- Application Information

AI Technical Summary

Problems solved by technology

Method used

Image

Examples

Embodiment Construction

[0022] The present invention will be further described below in conjunction with accompanying drawing:

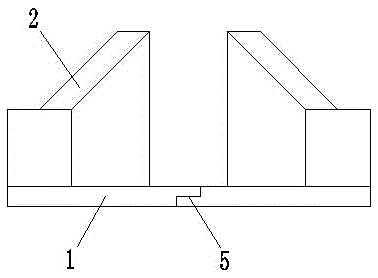

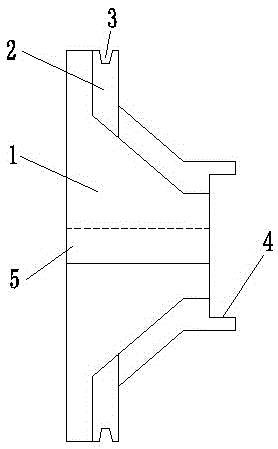

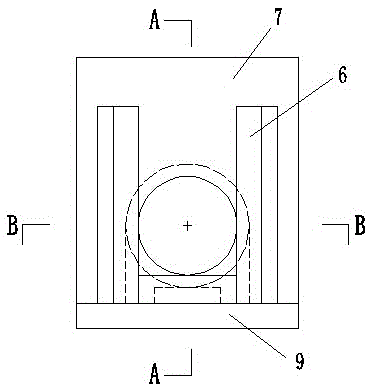

[0023] Such as Figure 1-9 As shown, a new type of assembled field culvert building. The field culvert building is composed of a figure-shaped wing wall connector, a culvert socket prefabricated part, a character wall insert block and a culvert pipe connection. The eight-shaped wing wall 2 is connected, and an internal connection groove 4 is provided at the end of the eight-shaped wing wall 2; the prefabricated part of the culvert socket is composed of the culvert bottom plate 9, the culvert wall 7 and the wall external connecting plate 6, and the culvert wall 7 There is a culvert pipe socket 8 on the top, and the culvert wall 7 and the wall external connecting plate 6 are closely arranged, and a door slot 10 is also provided between the culvert wall 7 and the wall external connecting plate 6; On both sides of the culvert wall 7, the culvert pipes are tightly connected to ...

PUM

Login to View More

Login to View More Abstract

Description

Claims

Application Information

Login to View More

Login to View More - R&D

- Intellectual Property

- Life Sciences

- Materials

- Tech Scout

- Unparalleled Data Quality

- Higher Quality Content

- 60% Fewer Hallucinations

Browse by: Latest US Patents, China's latest patents, Technical Efficacy Thesaurus, Application Domain, Technology Topic, Popular Technical Reports.

© 2025 PatSnap. All rights reserved.Legal|Privacy policy|Modern Slavery Act Transparency Statement|Sitemap|About US| Contact US: help@patsnap.com