Rail-traveling type hydraulic ditch cable trench trolley formwork system

A technology for trench cable trough and trolley formwork, which is applied in wellbore lining, tunnel lining, underground chamber, etc., can solve the problems of poor formwork operability, poor integrity, long cycle time, etc., so as to improve construction quality and construction efficiency , The effect of reducing the construction cost and the strength of the formwork

- Summary

- Abstract

- Description

- Claims

- Application Information

AI Technical Summary

Problems solved by technology

Method used

Image

Examples

Embodiment

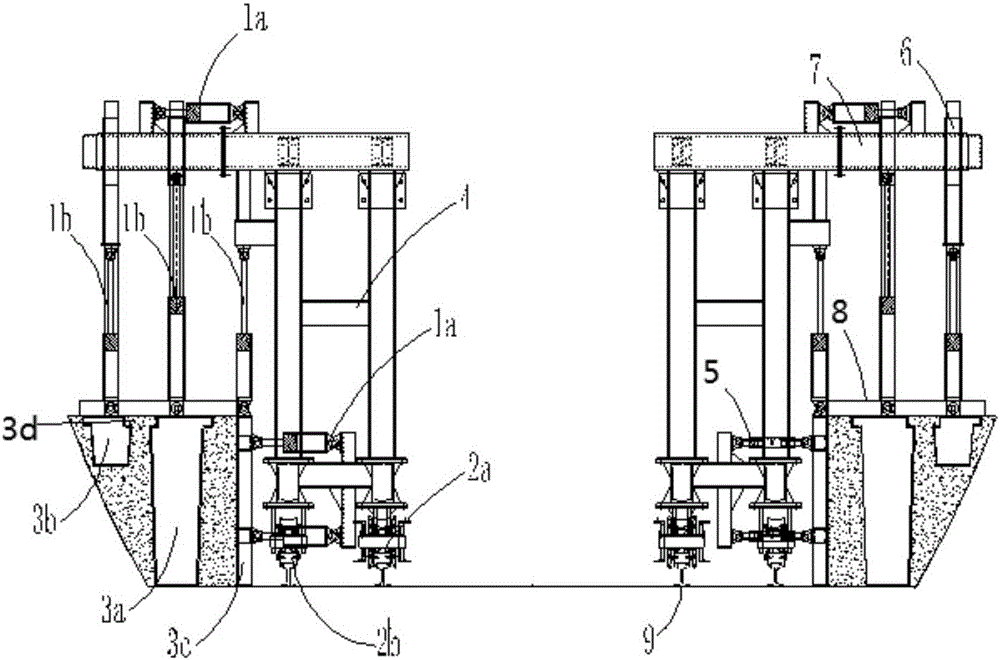

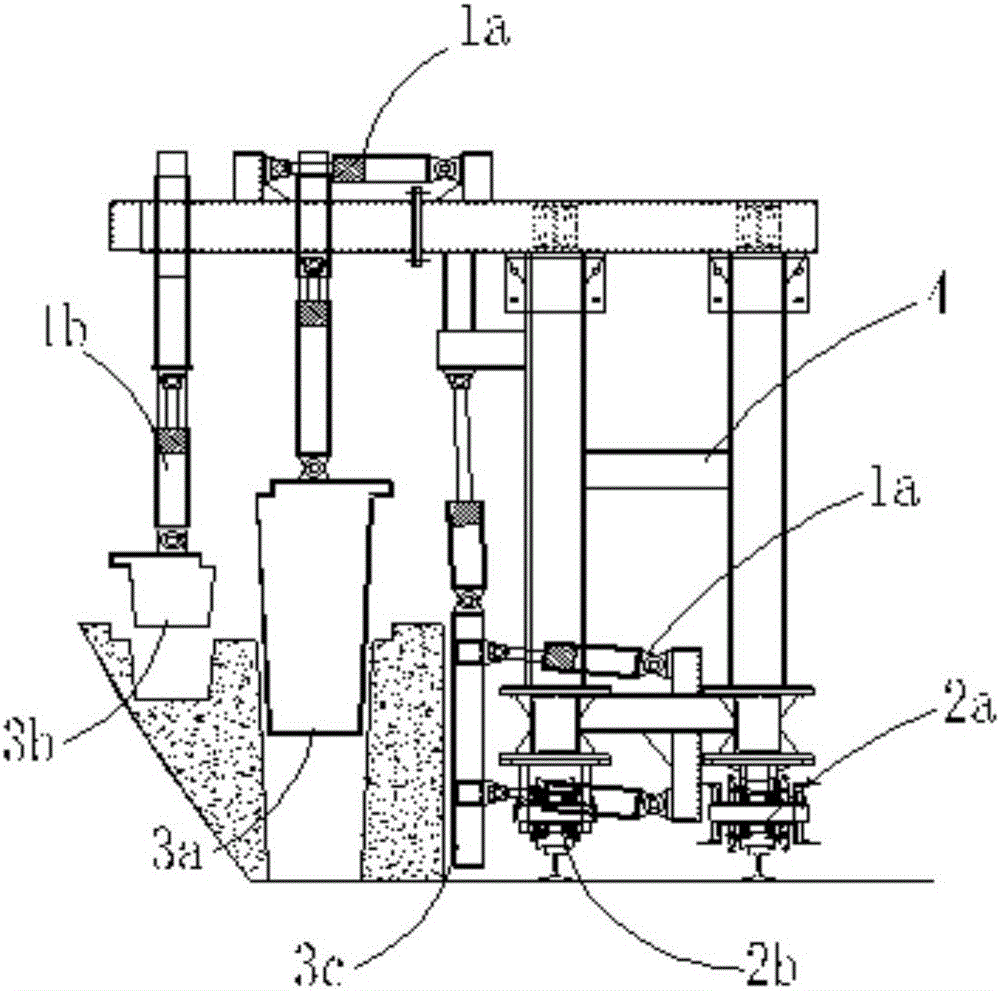

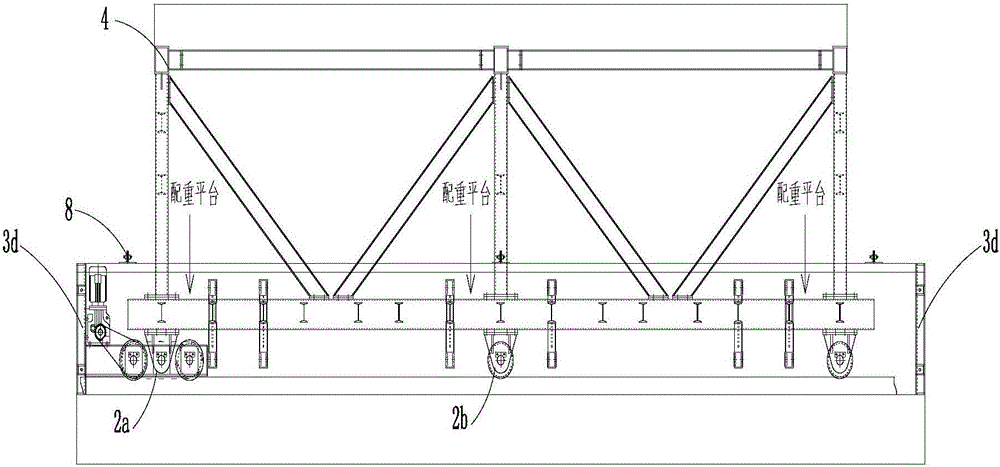

[0028] see figure 1 , rail-type hydraulic ditch cable trough formwork system, first install and fix the track 9 according to the design position, outside the construction section, assemble the components sequentially according to the design drawings, and the gutter cable trough trolley is driven by the motor to drive along the track 9 Move forward to the design position and fix it, start the hydraulic system 1 to adjust the outer steel formwork 3c and use the screw rod 5 to fine-tune it to the design position, use the vertical oil cylinder 1b to drive the vertical sliding shoe 6 to move down the water ditch steel formwork 3a and the cable channel steel formwork 3b in turn , use the top horizontal oil cylinder 1a to drive the horizontal sliding shoe 7 to fine-tune the water ditch steel formwork 3a and cable channel steel formwork 3b in place and fix the limit rod 8, install the end-end sealing steel formwork 3d, pour the concrete after the steel formwork system is accurately in ...

PUM

Login to View More

Login to View More Abstract

Description

Claims

Application Information

Login to View More

Login to View More - R&D

- Intellectual Property

- Life Sciences

- Materials

- Tech Scout

- Unparalleled Data Quality

- Higher Quality Content

- 60% Fewer Hallucinations

Browse by: Latest US Patents, China's latest patents, Technical Efficacy Thesaurus, Application Domain, Technology Topic, Popular Technical Reports.

© 2025 PatSnap. All rights reserved.Legal|Privacy policy|Modern Slavery Act Transparency Statement|Sitemap|About US| Contact US: help@patsnap.com