Novel smart gas meter motor valve

A gas meter, motor valve technology, applied in the direction of lift valve, valve details, valve device, etc., can solve the problems such as the inability to guarantee the reset of the ratchet double gear, the complex processing of incomplete gear components, and the large volume of the rack and pinion transmission. Achieve the effect of improving explosion-proof performance, simple structure and simplified structure

- Summary

- Abstract

- Description

- Claims

- Application Information

AI Technical Summary

Problems solved by technology

Method used

Image

Examples

Embodiment 1

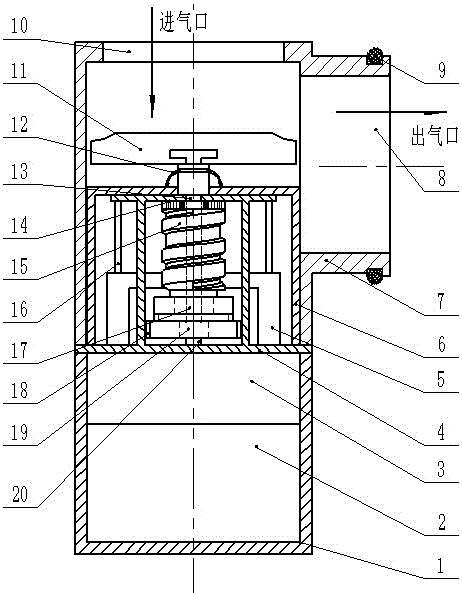

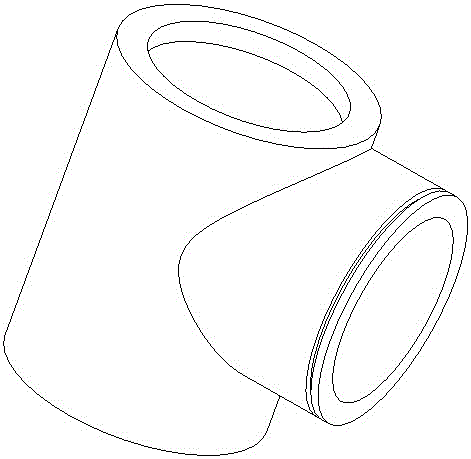

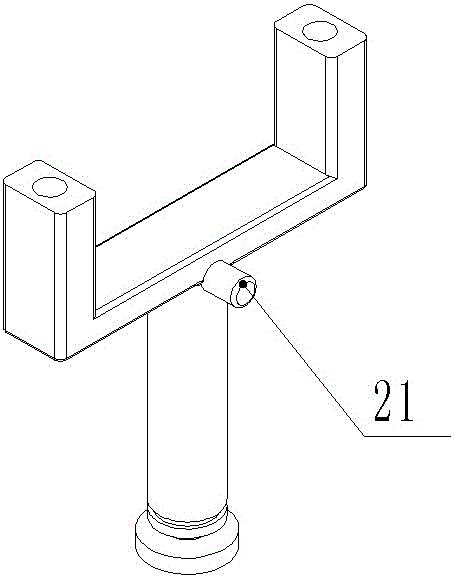

[0030] A new type of intelligent gas meter motor valve, consisting of a valve body, a motor (2), a speed change device (3), an anti-lock mechanism (17), a screw transmission device (15), a coil spring assembly (14) and a valve stem (5 ) composition; such as figure 1As shown, it is characterized in that: the valve body is provided with an air outlet (8), an air inlet (10), a valve stem hole (23) and a valve cavity; the motor (2) is fixedly installed on the inner wall of the valve cavity, and the motor ( 2) Connected to the input shaft of the transmission device, the cylindrical gear 1 (18) on the output shaft (20) of the transmission device meshes with the anti-lock mechanism (17) installed on the partition (4) and set on the transmission shaft (13) , and drives the valve stem (5) that cooperates with the screw transmission device (15) and the coil spring assembly (14) fixedly installed on the screw transmission device (15) to realize closing and opening of the valve; the scre...

Embodiment 2

[0034] A new type of intelligent gas meter motor valve, consisting of a valve body, a motor (2), a speed change device (3), an anti-lock mechanism (17), a screw transmission device (15), a coil spring assembly (14) and a valve stem (5 ) composition; such as figure 1 As shown, it is characterized in that: the valve body is provided with an air outlet (8), an air inlet (10), a valve stem hole (23) and a valve cavity; the motor (2) is fixedly installed on the inner wall of the valve cavity, and the motor ( 2) Connected to the input shaft of the transmission device, the cylindrical gear 1 (18) on the output shaft (20) of the transmission device meshes with the anti-lock mechanism (17) installed on the partition (4) and set on the transmission shaft (13) , and drives the valve stem (5) that cooperates with the screw transmission device (15) and the coil spring assembly (14) fixedly installed on the screw transmission device (15) to realize closing and opening of the valve; the scr...

PUM

Login to View More

Login to View More Abstract

Description

Claims

Application Information

Login to View More

Login to View More - R&D

- Intellectual Property

- Life Sciences

- Materials

- Tech Scout

- Unparalleled Data Quality

- Higher Quality Content

- 60% Fewer Hallucinations

Browse by: Latest US Patents, China's latest patents, Technical Efficacy Thesaurus, Application Domain, Technology Topic, Popular Technical Reports.

© 2025 PatSnap. All rights reserved.Legal|Privacy policy|Modern Slavery Act Transparency Statement|Sitemap|About US| Contact US: help@patsnap.com