Plant facilities management system and plant facilities management system control method

A technology for management systems and factory equipment, applied in general control systems, control/adjustment systems, test/monitoring control systems, etc., can solve problems such as missing abnormal omens, and achieve the effect of effective analysis

- Summary

- Abstract

- Description

- Claims

- Application Information

AI Technical Summary

Problems solved by technology

Method used

Image

Examples

Embodiment 1

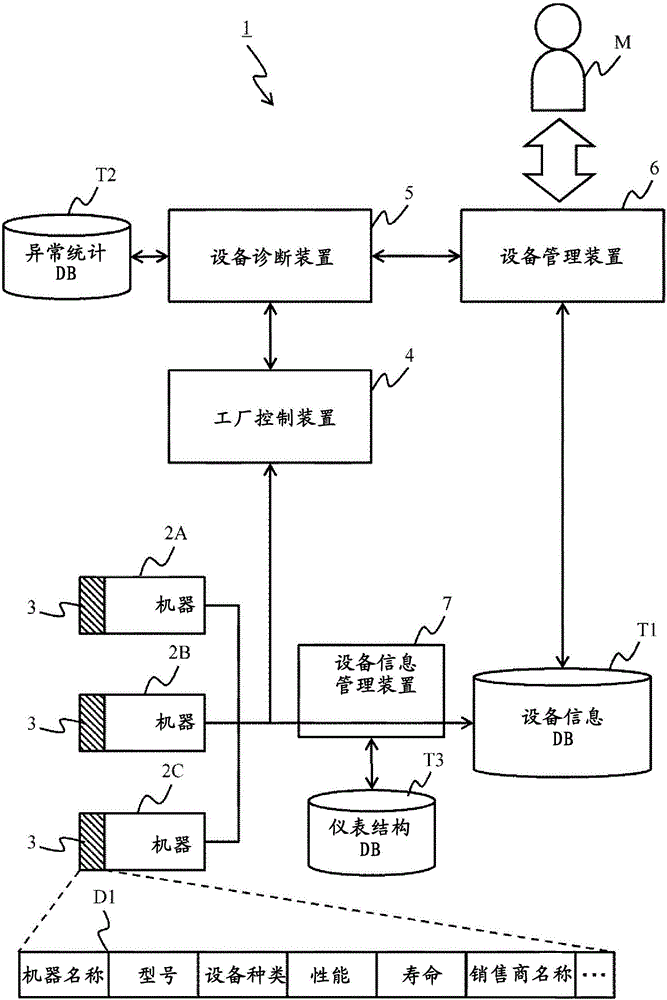

[0029] figure 1 The overall structure of the plant equipment management system 1 is shown. For example, a plurality of devices 2A to 2C are installed in factories such as power plants and chemical plants. When there is no need to distinguish the respective machines 2A to 2C, they are referred to as machine 2 .

[0030] Each machine 2 is, for example, a sensor, an actuator, a controller, etc., specifically corresponding to a temperature sensor, a pressure sensor, a flow sensor, a viscosity sensor, a distance sensor, a quality sensor, a color sensor, an illumination sensor, a gas sensor, a solenoid valve, a pneumatic Regulating valves, solenoids, heaters, refrigerators, motors, generators, transformers, turbines, boilers, pumps, compressors, mixers, fans, filters, sequencers, control panels, regulators, recorders, etc. That is, each device 2 includes both main equipment and incidental equipment.

[0031] Each device 2 includes a device information storage unit 3 for storing d...

Embodiment 2

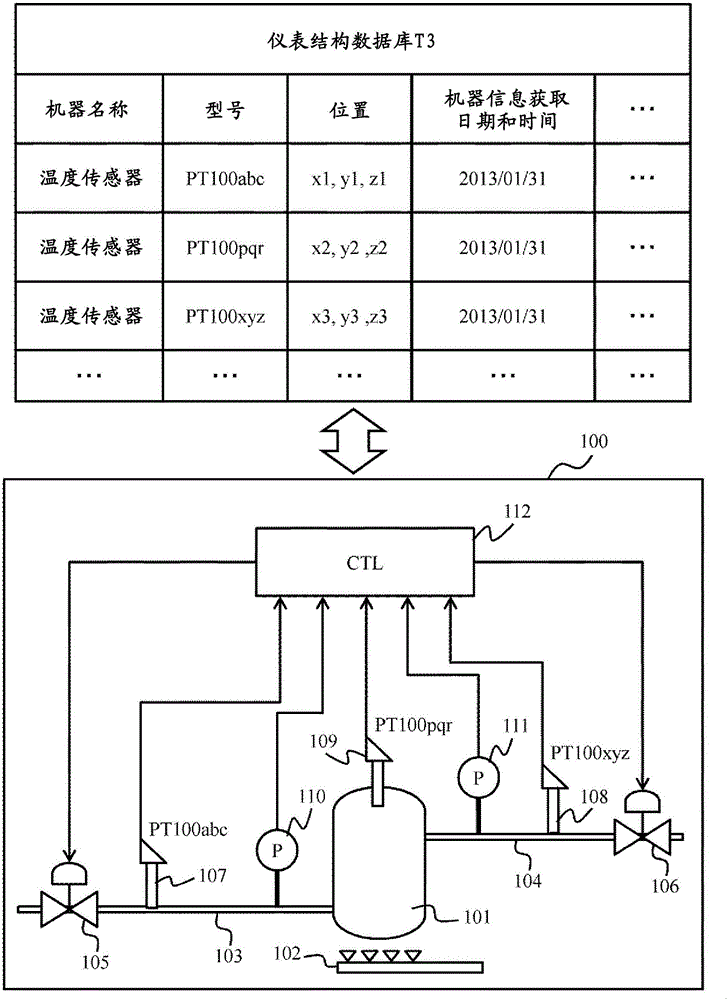

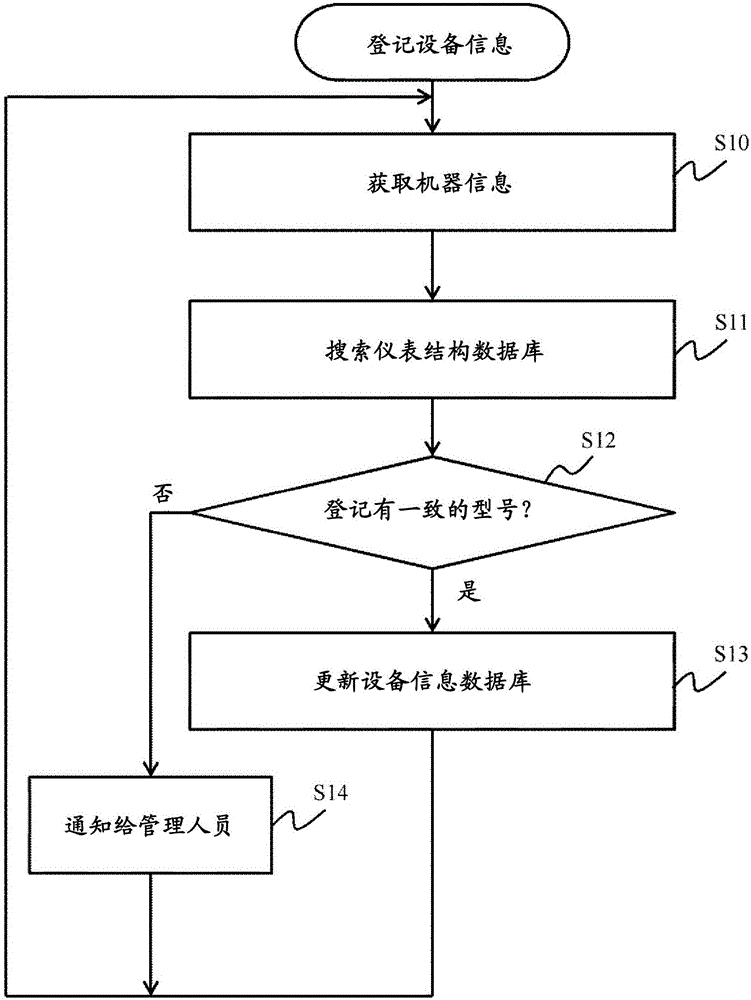

[0073] use Figure 6 and Figure 7 A second embodiment will be described. This embodiment corresponds to a modified example of the first embodiment, so the description will focus on differences from the first embodiment. In the present embodiment, the device to be replaced is specified on the device configuration diagram 100, and the device information database T1 is updated with device information from the newly installed device.

[0074] Figure 6 It is an explanatory diagram showing the instrument configuration database T3 and the instrument configuration diagram 100 . The devices 2 in the factory are appropriately replaced in order to cope with aging or to improve measurement accuracy, for example.

[0075] The manager designates the device to be replaced (here, the tank temperature sensor 109 ) on the instrument configuration diagram 100 . In order to distinguish the designated replacement device from other devices, the display method may be changed by blinking or th...

PUM

Login to View More

Login to View More Abstract

Description

Claims

Application Information

Login to View More

Login to View More - R&D

- Intellectual Property

- Life Sciences

- Materials

- Tech Scout

- Unparalleled Data Quality

- Higher Quality Content

- 60% Fewer Hallucinations

Browse by: Latest US Patents, China's latest patents, Technical Efficacy Thesaurus, Application Domain, Technology Topic, Popular Technical Reports.

© 2025 PatSnap. All rights reserved.Legal|Privacy policy|Modern Slavery Act Transparency Statement|Sitemap|About US| Contact US: help@patsnap.com