Intelligent lacquer tree cutting collecting device

A collection device and cutting device technology, applied in forestry, application, agriculture, etc., can solve problems such as failure to promote a virtuous cycle of the market, the impact of industrial production of lacquer, and the inability to increase the output of lacquer, so as to facilitate public learning and ensure good health. , the effect of facilitating promotion

- Summary

- Abstract

- Description

- Claims

- Application Information

AI Technical Summary

Problems solved by technology

Method used

Image

Examples

Embodiment 1

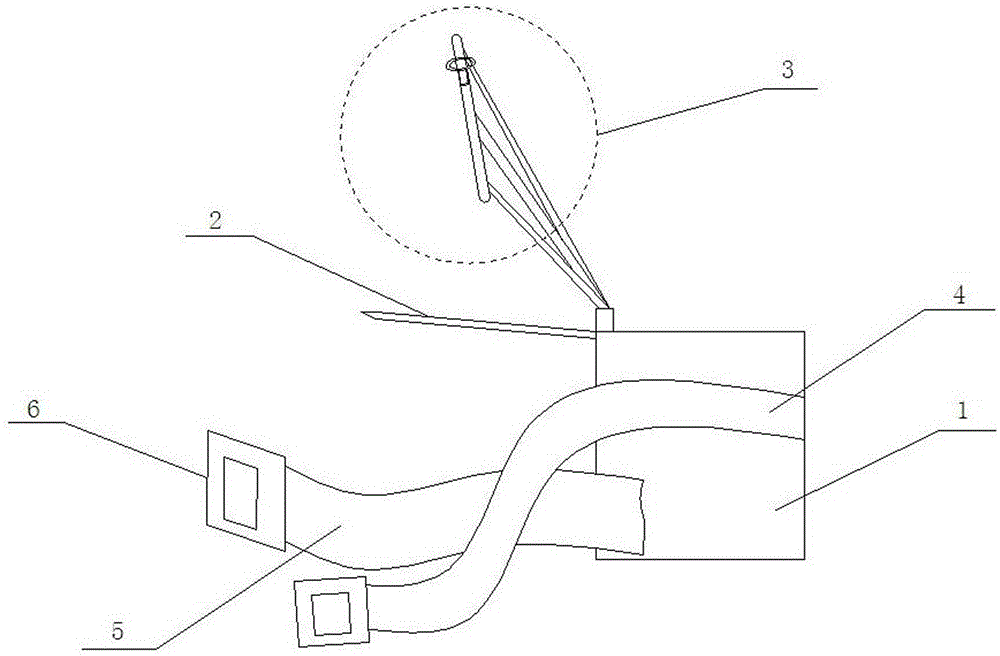

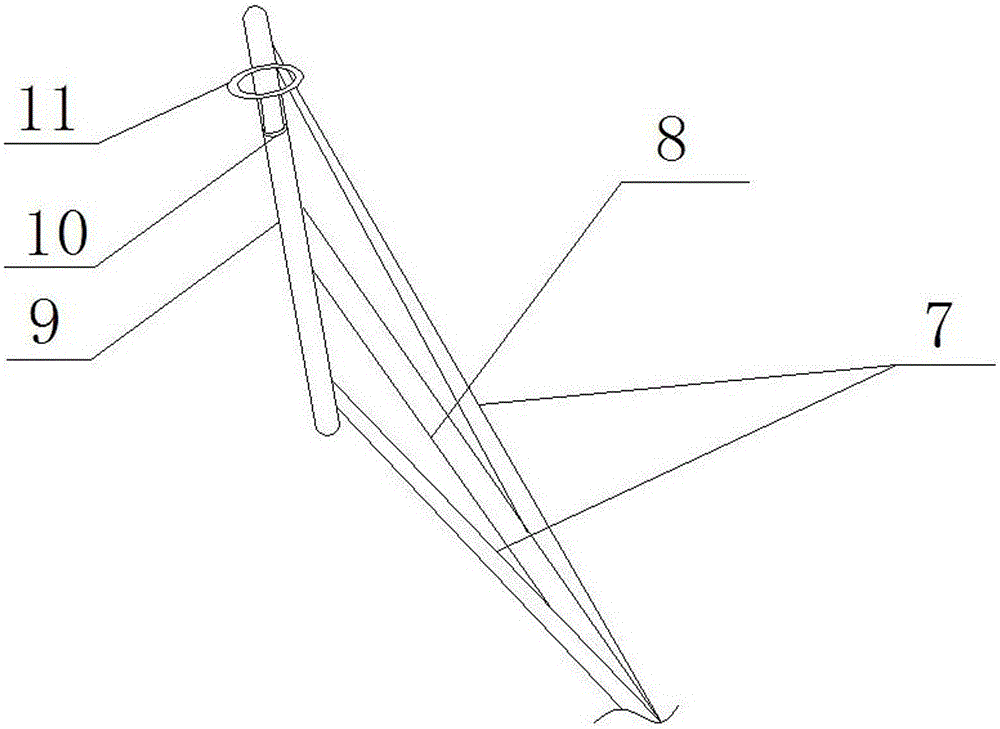

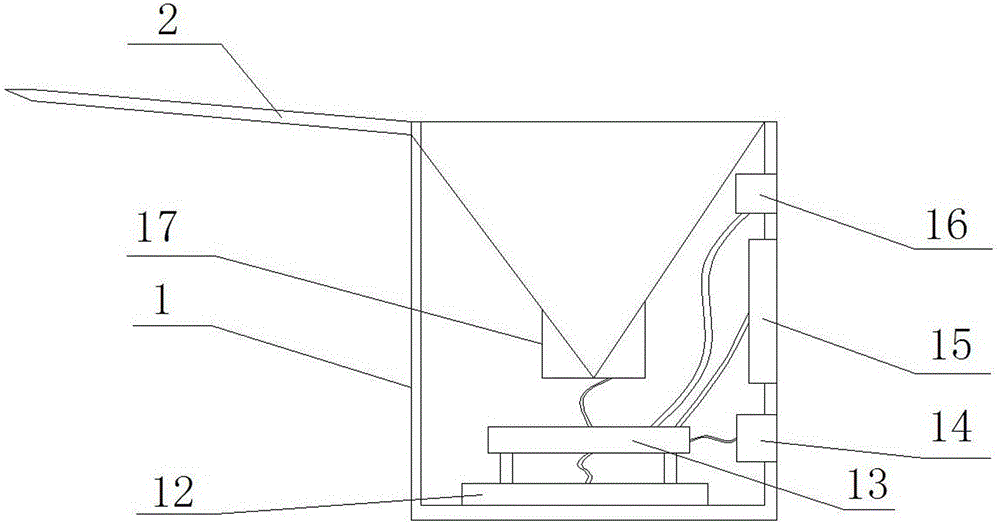

[0029] An intelligent lacquer tree cutting and collecting device 1, comprising a collecting device 1 and a cutting device 3, characterized in that: one end of the top of the collecting device 1 is provided with a plug-in guide groove 2, and the top of the collecting device 1 is connected to the plug-in guide groove 2 The upper end of the cutting device 3 is connected with the cutting device 3; the cutting device 3 is connected with the collection device 1 with a shaft; the collection device 1 is a barrel-shaped device, and the inside of the collection device 1 is conical, and the collection device 1 An upper fixing belt 4 is provided on the upper surface of the outer surface, and a lower fixing belt 5 is provided on the lower outer surface of the collection device 1; an electronic monitoring and control device is provided inside the collection device 1; the cutting device 3 includes a knife rail 9, Telescopic connecting rod 8, telescopic fixed connecting rod 7, blade 10; blad...

Embodiment 2

[0036] Working principle of the present invention: when using the present invention, the insertion guide groove 2 of the present invention can be inserted in the bark to facilitate the collection of lacquer sap, and the upper fixing belt 4 and the lower fixing belt 5 are bound and fixed around the trunk, so that the whole After the collecting device 1 is fixed, the cutting device 3 is turned over, the inclination of the knife rail 9 is adjusted by the telescopic fixed connecting rod 7, the direction of the knife is adjusted, the blade 10 is slid on the inside of the knife rail 9 by the handle 11, and the bark of the sumac tree is cut. Complete the collection of lacquer.

Embodiment 3

[0038] In the present invention, the pressure sensor 17 in the electronic monitoring control device can collect the collected varnish weight, transmit the data to the main control circuit board 13, and after data processing, the alarm signal will be sent to nearby via the alarm transmitter. The terminal is convenient for notifying workers to collect paint in time; workers can also understand the paint collection data through the display 15, which is convenient for controlling and collecting information; workers can also set the collection time through the control button 14, and when the timing time arrives, a signal can be sent to notify the workers to collect paint .

PUM

Login to View More

Login to View More Abstract

Description

Claims

Application Information

Login to View More

Login to View More - R&D

- Intellectual Property

- Life Sciences

- Materials

- Tech Scout

- Unparalleled Data Quality

- Higher Quality Content

- 60% Fewer Hallucinations

Browse by: Latest US Patents, China's latest patents, Technical Efficacy Thesaurus, Application Domain, Technology Topic, Popular Technical Reports.

© 2025 PatSnap. All rights reserved.Legal|Privacy policy|Modern Slavery Act Transparency Statement|Sitemap|About US| Contact US: help@patsnap.com