Sedimentation tank that can be cleaned automatically for road and bridge construction

An automatic cleaning and sedimentation tank technology, applied in the sedimentation tank and other directions, can solve the problems of unsatisfactory cleaning effect, environmental pollution, oil consumption and other problems, and achieve the effects of low construction cost, flexibility and fast operation speed.

- Summary

- Abstract

- Description

- Claims

- Application Information

AI Technical Summary

Problems solved by technology

Method used

Image

Examples

Embodiment Construction

[0010] The specific embodiments of the present invention are as follows:

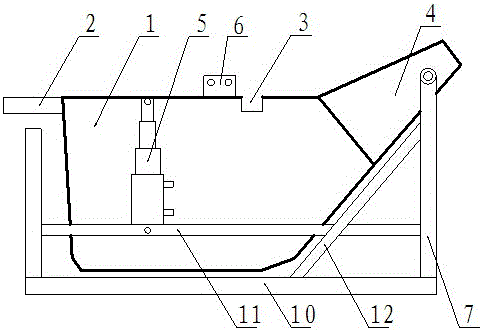

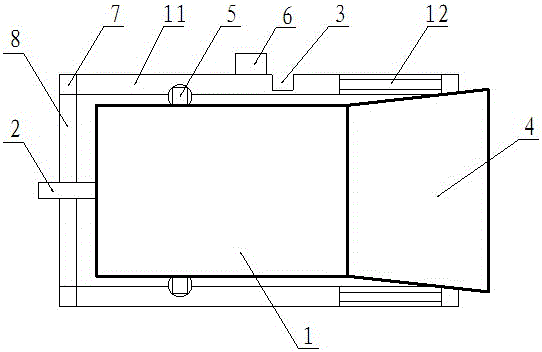

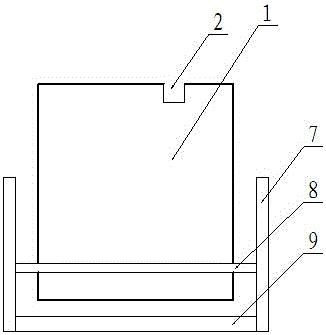

[0011] Fix two longitudinal beams (10) between the ends of the two transverse beams (8), respectively fix the upright column (7) on each corner connecting the transverse beam (8) and the longitudinal beam (10), 7) At the upper end, a horizontal connecting beam (9) and a longitudinal connecting beam (11) are used to connect the vertical column (7) vertically and horizontally to form a box. A sedimentation tank (1) is set between the boxes. A sewage tank (3) is arranged on the side, a drainage groove (2) is arranged at one end of the longitudinal direction of the sedimentation tank (1), and a drainage groove (4) is arranged at the other end. The two sides of the drainage groove (4) are respectively connected to the vertical column (7). ) Hinge connection, using diagonal bracing (12) to connect the column (7), the longitudinal beam (10) and the longitudinal connecting beam (11) to each other, between the two ...

PUM

Login to View More

Login to View More Abstract

Description

Claims

Application Information

Login to View More

Login to View More - R&D

- Intellectual Property

- Life Sciences

- Materials

- Tech Scout

- Unparalleled Data Quality

- Higher Quality Content

- 60% Fewer Hallucinations

Browse by: Latest US Patents, China's latest patents, Technical Efficacy Thesaurus, Application Domain, Technology Topic, Popular Technical Reports.

© 2025 PatSnap. All rights reserved.Legal|Privacy policy|Modern Slavery Act Transparency Statement|Sitemap|About US| Contact US: help@patsnap.com