Preparation method, desorption method and applications of carbon nano-tube/polyaniline composite adsorption material with characteristic of easy lightweight separation

A composite adsorption material, carbon nanotube technology, applied in chemical instruments and methods, adsorption water/sewage treatment, other chemical processes, etc., can solve the problems of difficult separation of adsorption materials, high cost, low cost, reduced density, preparation simple craftsmanship

- Summary

- Abstract

- Description

- Claims

- Application Information

AI Technical Summary

Problems solved by technology

Method used

Image

Examples

specific Embodiment approach 1

[0023] Specific Embodiment 1: The preparation method of the lightweight and easy-to-separate carbon nanotube / polyaniline composite adsorption material provided in this embodiment is carried out according to the following steps:

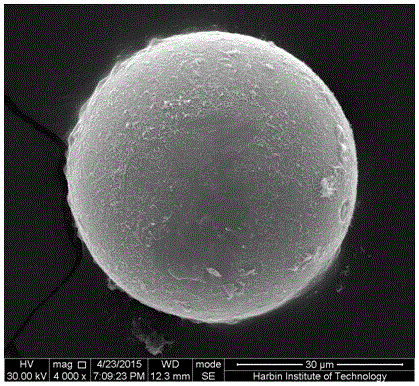

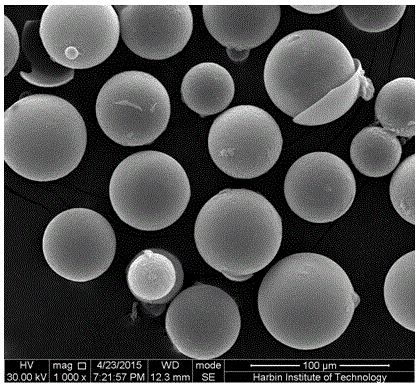

[0024] 1. Prepare a sodium hydroxide solution with a concentration of 0.3~0.8mol / L, disperse the hollow glass microspheres in the sodium hydroxide solution, and treat them for 0.5~2.5h under stirring conditions, and wash the treated hollow glass microspheres with distilled water until neutral.

[0025] 2. Weigh polydiallyldimethylammonium chloride, sodium chloride and distilled water according to the ratio of 0.3~0.6g:20~30g:500mL Sodium and distilled water and polydiallyl dimethyl ammonium chloride, sodium chloride dissolved in water to obtain a sodium chloride solution of polydiallyl dimethyl ammonium chloride. Disperse the hollow glass microspheres treated in step 1 in distilled water, and add the above polydiallyl dimethyl ammonium chloride solut...

specific Embodiment approach 2

[0043] Specific embodiment two: the preparation method of the light and easily separable carbon nanotube / polyaniline composite adsorption material provided by the present embodiment is carried out according to the following steps:

[0044] 1. Prepare a sodium hydroxide solution with a concentration of 0.5 mol / L, disperse the hollow glass microspheres in the sodium hydroxide solution, and treat for 2 hours under stirring conditions, and wash the treated hollow glass microspheres with distilled water until neutral.

[0045] 2. Weigh polydiallyldimethylammonium chloride, sodium chloride, and distilled water according to the ratio of polydiallyldimethylammonium chloride, sodium chloride, and distilled water to 0.5g:29.2g:500mL And dissolving polydiallyl dimethyl ammonium chloride and sodium chloride in water to obtain a sodium chloride solution of polydiallyl dimethyl ammonium chloride. Disperse the hollow glass microspheres treated in step 1 in distilled water, and add the above ...

PUM

| Property | Measurement | Unit |

|---|---|---|

| Adsorption capacity | aaaaa | aaaaa |

Abstract

Description

Claims

Application Information

Login to view more

Login to view more - R&D Engineer

- R&D Manager

- IP Professional

- Industry Leading Data Capabilities

- Powerful AI technology

- Patent DNA Extraction

Browse by: Latest US Patents, China's latest patents, Technical Efficacy Thesaurus, Application Domain, Technology Topic.

© 2024 PatSnap. All rights reserved.Legal|Privacy policy|Modern Slavery Act Transparency Statement|Sitemap