Machine and method for installing dry battery electric torch front conductive bridge

A conductive bridge and flashlight technology, which is applied to the parts of lighting devices, lighting devices, lighting and heating equipment, etc., can solve the problems of large impact on production efficiency, high labor intensity, scratches on iron bridge feet, etc., to improve production efficiency , Reduce work intensity, improve the effect of enterprise production efficiency

- Summary

- Abstract

- Description

- Claims

- Application Information

AI Technical Summary

Problems solved by technology

Method used

Image

Examples

Embodiment Construction

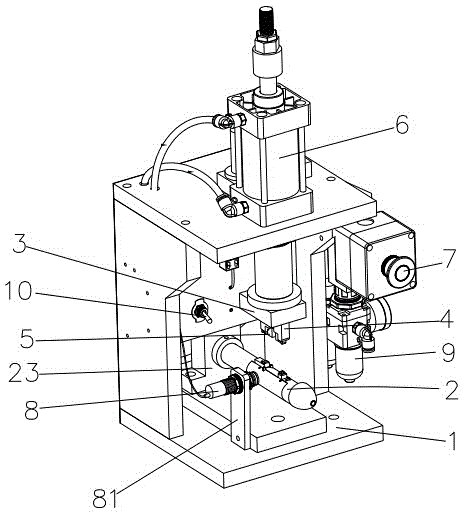

[0025] Such as Figure 3-8 As shown, a conductive bridge installation machine before a dry battery flashlight of the present invention includes a body 1, a positioning support rod 2, an installation base 3, a foot folding mold 4, a compression mold 5, a cylinder 6 and a start switch 7.

[0026] Wherein, the above-mentioned positioning support bar 2 includes a cross bar 21 and a positioning slider 22 installed in the cross bar and capable of moving up and down. One end of the cross bar 21 is fixed on the middle part of the body through the installation seat plate 23, and the other end is suspended in the air. The positioning slider 22 includes two positioning bosses, a connecting plate 221 connecting the bottom ends of the two positioning bosses, mounting ears 222 mounted on the positioning bosses and two positioning washers 223 . The two positioning protrusions are respectively a front positioning protrusion 224 close to the free end of the cross bar 21 and a rear positioning...

PUM

Login to View More

Login to View More Abstract

Description

Claims

Application Information

Login to View More

Login to View More - R&D

- Intellectual Property

- Life Sciences

- Materials

- Tech Scout

- Unparalleled Data Quality

- Higher Quality Content

- 60% Fewer Hallucinations

Browse by: Latest US Patents, China's latest patents, Technical Efficacy Thesaurus, Application Domain, Technology Topic, Popular Technical Reports.

© 2025 PatSnap. All rights reserved.Legal|Privacy policy|Modern Slavery Act Transparency Statement|Sitemap|About US| Contact US: help@patsnap.com