Method for manufacturing buoy and buoy manufactured through method

A manufacturing method and lifebuoy technology, which are applied to lifesaving in water, ships, and ship safety, etc., can solve problems such as high cost, impact on service life, and hard plastics are easily damaged, and achieve simple manufacturing methods, improved foaming quality, and improved foaming. The effect of beauty

- Summary

- Abstract

- Description

- Claims

- Application Information

AI Technical Summary

Problems solved by technology

Method used

Image

Examples

Embodiment 1

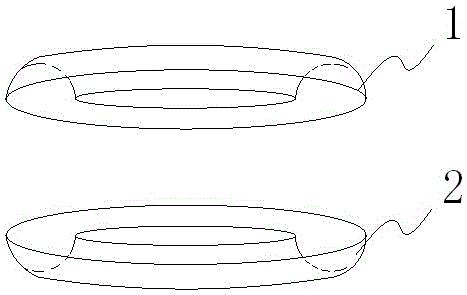

[0031] Such as figure 1 As shown, the present embodiment proposes a manufacturing method of a foam-molded solid buoy. The mold structure adopted is as follows: an upper mold 1 and a lower mold 2 that can be fastened together, and the upper mold 1 and the lower mold 2 are both Annular groove structure; the manufacturing method includes the following steps:

[0032] A: Place the elastic foam material evenly in the lower mold 2, and fasten the upper mold 1 and the lower mold 2;

[0033] B: Heat the upper mold 1 and the lower mold 2, first raise the temperature inside the mold to 170-180°C, so that the elastic foam material in the mold is heated and softened, and keep it for 30-40 minutes; then make the mold The temperature inside is raised to 185°C and maintained for 50-80 seconds;

[0034] C: Loosen the upper mold 1 and the lower mold 2, and lift the upper mold 1, so that the elastic foam material inside the upper mold 1 and the lower mold 2 expands, forming a semi-finished li...

Embodiment 2

[0038] This embodiment proposes a manufacturing method of a foam-molded solid two-color life buoy, which uses the same mold as in Example 1 during its manufacture; the manufacturing method comprises the following steps:

[0039] A: Evenly place the first elastic foam material in the lower mold 2;

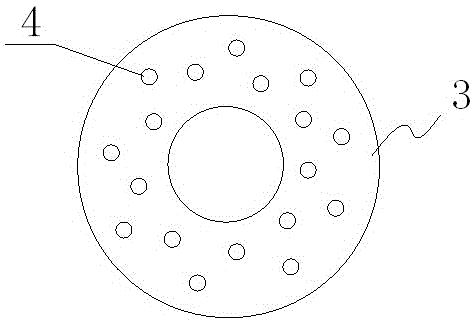

[0040] B: Cover a partition 3 on the lower mold 2, and evenly place the second elastic foam material on the partition 3, and then fasten the upper mold 1 and the lower mold 2;

[0041] C: heating the upper mold 1 and the lower mold 2 to increase the temperature in the mold;

[0042] D: Loosen the upper mold 1 and the lower mold 2, and lift the upper mold 1, so that the elastic foam material inside the upper mold 1 and the lower mold 2 expands, forming a semi-finished life buoy;

[0043] E: Trim the semi-finished lifebuoy to get the finished lifebuoy.

[0044] The separator 3 in the step B is an annular plate structure, which is pre-made by the third elastic foam material whose sof...

Embodiment 3

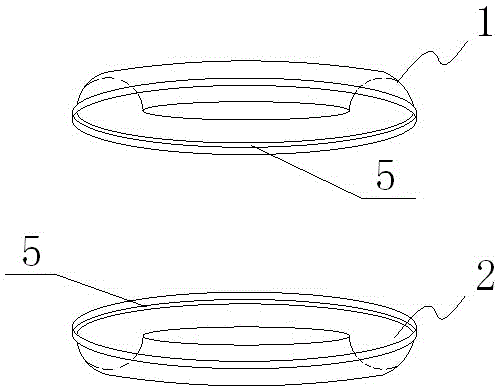

[0048] Different from Example 2, the mold used in this example is as image 3 As shown, the bottom periphery of the upper mold 1 and the top periphery of the lower mold 2 are provided with protruding partition accommodating grooves 5, and the foaming expansion rate of the partition 3 in the B step is lower than that of the first The expansion ratio of the elastic foam material and the second elastic foam material.

[0049] The outer peripheral diameter of dividing plate 3 is identical with the outer circumferential diameter of dividing plate accommodating groove 5, is all greater than the outer circumference of the annular groove of lower mold 2, upper mold 1, even in softening stage like this, the first elastic foaming material, the second elastic The foaming material is mixed with the partition 3, and it will not affect the outer surface of the partition 3, and when the foam expands, because the expansion rate of the partition 3 is lower than that of the first elastic foam m...

PUM

Login to View More

Login to View More Abstract

Description

Claims

Application Information

Login to View More

Login to View More - R&D Engineer

- R&D Manager

- IP Professional

- Industry Leading Data Capabilities

- Powerful AI technology

- Patent DNA Extraction

Browse by: Latest US Patents, China's latest patents, Technical Efficacy Thesaurus, Application Domain, Technology Topic, Popular Technical Reports.

© 2024 PatSnap. All rights reserved.Legal|Privacy policy|Modern Slavery Act Transparency Statement|Sitemap|About US| Contact US: help@patsnap.com