Method for estimating non-Newtonian index of resin material by utilizing injection molding machine

A non-Newtonian index and resin material technology, applied in the field of injection molding, can solve the problems of capillary structure and assembly complexity and high cost

- Summary

- Abstract

- Description

- Claims

- Application Information

AI Technical Summary

Problems solved by technology

Method used

Image

Examples

Embodiment Construction

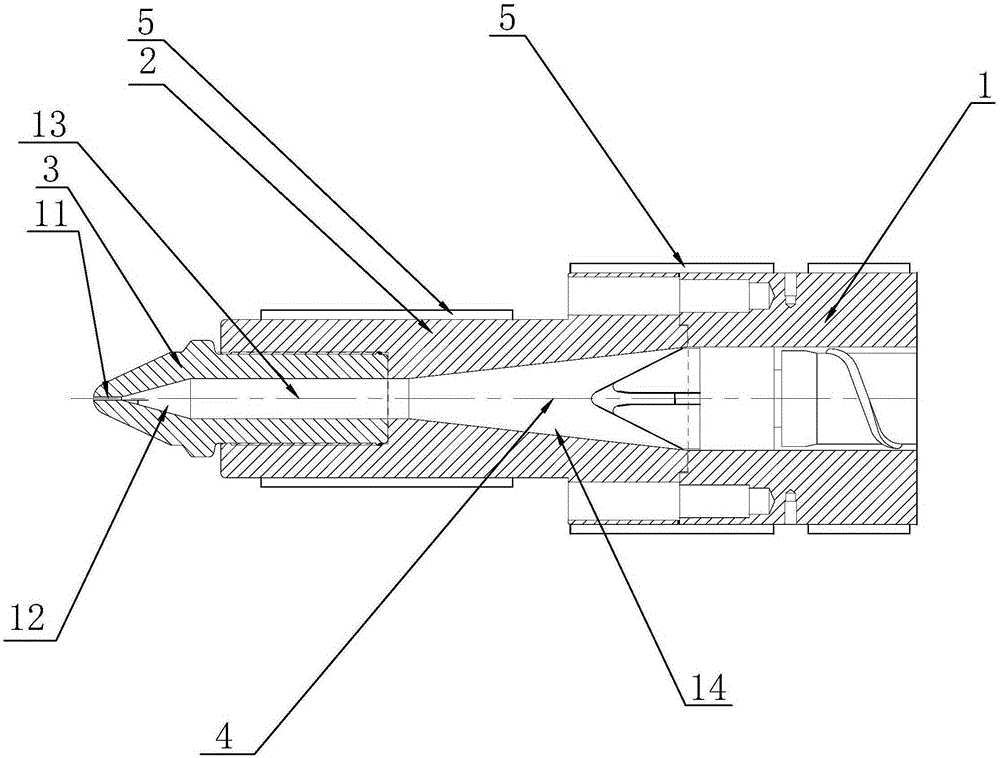

[0034] refer to figure 1 , the present invention is a method for estimating the non-Newtonian exponent of a resin material using an injection molding machine, comprising the following steps:

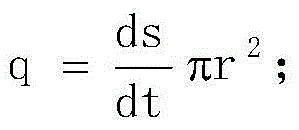

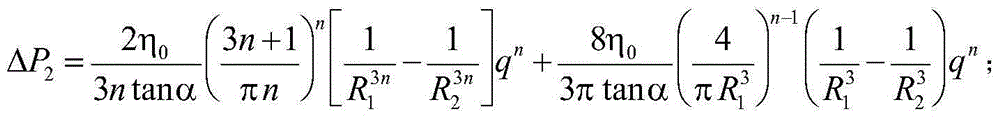

[0035] 1) Record the parameters of the injection molding machine, including the inner diameter r of the barrel 1 and the structural parameters in the range from the pressure sensor 4 to the front end of the nozzle 3, including the radius R and length l of each circular tube flow channel, and the radius R1 of the two ends of the conical tube flow channel and R2 and the convergence angle α of the conical pipe flow channel;

[0036] 2) After heating the injection molding machine for a period of time, the temperature at the nozzle 3 and the adapter 2 on the injection molding machine is constant and evenly distributed, and the air injection test is started, and the temperature of the injection molding machine is still maintained during the air injection test. A constant and uniform distribut...

PUM

Login to View More

Login to View More Abstract

Description

Claims

Application Information

Login to View More

Login to View More - R&D

- Intellectual Property

- Life Sciences

- Materials

- Tech Scout

- Unparalleled Data Quality

- Higher Quality Content

- 60% Fewer Hallucinations

Browse by: Latest US Patents, China's latest patents, Technical Efficacy Thesaurus, Application Domain, Technology Topic, Popular Technical Reports.

© 2025 PatSnap. All rights reserved.Legal|Privacy policy|Modern Slavery Act Transparency Statement|Sitemap|About US| Contact US: help@patsnap.com