Multi-station flexible clamping device and method

A clamping device and multi-station technology, applied in packaging, transportation and packaging, rigid/semi-rigid container manufacturing, etc., can solve the problem of flexible high-precision clamping of stations without internal mold positioning, etc. Achieve the effects of function and efficiency improvement, energy saving and consumption reduction structure simplification, and improvement of processing speed and efficiency

- Summary

- Abstract

- Description

- Claims

- Application Information

AI Technical Summary

Problems solved by technology

Method used

Image

Examples

Embodiment Construction

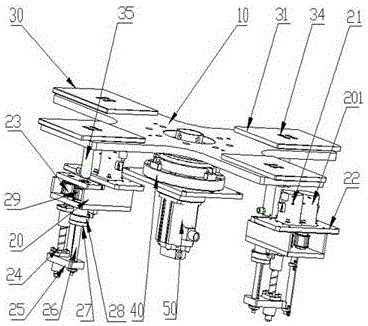

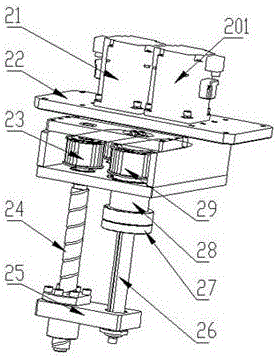

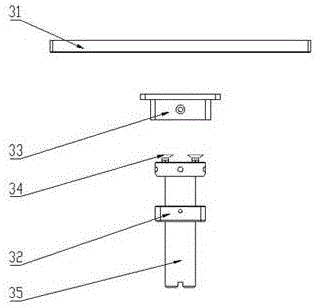

[0024] like figure 1 As shown, a multi-station flexible clamping device according to a specific embodiment of the present invention includes an upper large turntable 10 , a small turntable power assembly 20 , a lower small turntable 30 , a motor flange 40 , and a reduction motor 50 . The large turntable 10 on the upper floor links to each other with the reduction motor 50, and the reduction motor 50 is positioned at the central part of the large turntable 10 on the upper floor, and is fixed by the motor flange 40. There are four lower floor small turntables 30, which are fixedly installed on four sides of the upper floor large turntable 10 by four guide seats 33 respectively. The small turntable power combination 20 is located below the lower floor small turntable 30 and can be connected to it flexibly, and the small turntable power combination 20 is only arranged in the fixed direction of the two stations of shoveling and folding. The geared motor 50 starts, and the upper fl...

PUM

Login to View More

Login to View More Abstract

Description

Claims

Application Information

Login to View More

Login to View More - R&D

- Intellectual Property

- Life Sciences

- Materials

- Tech Scout

- Unparalleled Data Quality

- Higher Quality Content

- 60% Fewer Hallucinations

Browse by: Latest US Patents, China's latest patents, Technical Efficacy Thesaurus, Application Domain, Technology Topic, Popular Technical Reports.

© 2025 PatSnap. All rights reserved.Legal|Privacy policy|Modern Slavery Act Transparency Statement|Sitemap|About US| Contact US: help@patsnap.com