A fuel engine and electric motor linkage separation system

A fuel engine and separation system technology, which is applied to the layout of multiple prime movers, power devices, and air pressure power devices of general power devices, can solve problems such as damage, uneven power transmission, and burst transmission structures, and achieve The effect of safe and durable use, increased force bearing area, and reliable transmission

- Summary

- Abstract

- Description

- Claims

- Application Information

AI Technical Summary

Problems solved by technology

Method used

Image

Examples

Embodiment 1

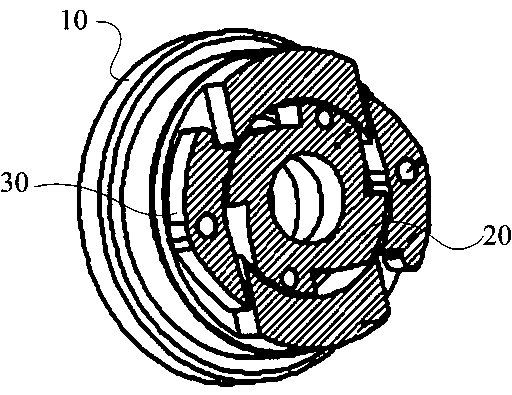

[0023] refer to image 3 The schematic diagram of the structure is shown.

[0024] A fuel engine and electric motor linkage separation system according to an embodiment of the present invention includes a driving disc 10 and a driven disc 20 of a clutch mechanism, the driving disc 10 is connected to the fuel engine power output shaft, and the power of the driven disc and the motor The output shaft 11 is connected, and the power output shaft 11 of the electric motor is also the power output shaft of the clutch mechanism.

[0025] The end face of the driving disc 10 has an inner cavity, the driven disc 20 is rotatably arranged in the inner cavity, the inner cavity wall of the driving disc 10 is provided with a notch groove for accommodating the clutch block 30, and the clutch block 30 is rotatably arranged in the notch groove Inside.

[0026] And there are at least two clutch blocks, which are symmetrically distributed on the inner cavity wall of the driving disc 10, preferabl...

Embodiment 2

[0035] refer to Figure 9 The schematic diagram of the structure is shown.

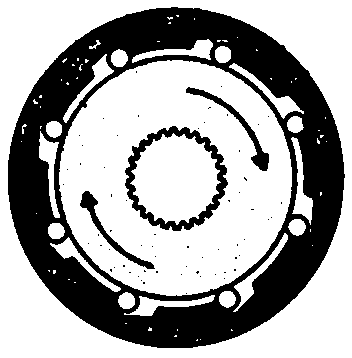

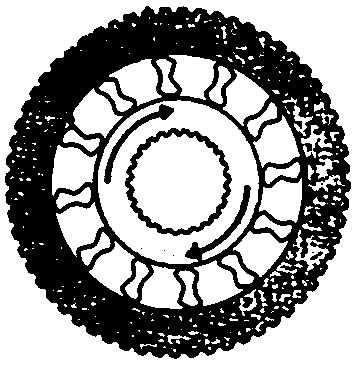

[0036] In this embodiment, the driving disc 10 is rotatably disposed in the inner cavity of the driven disc 20, and the clutch block 30 is rotatably disposed on the end surface of the driving disc 10. There are at least two clutch blocks 30, which are symmetrically distributed on the driving disc 10. On the wall of the lumen, preferably two pieces in this embodiment.

[0037] The inner cavity wall of the driven disc 20 is recessed to form a ratchet pawl 21, and a matching convex surface 33 is set on the outer wall of the clutch block 30. When the driving disc 10 is running, the clutch block is under the action of centrifugal force. The concave ratchet pawl 21 card contact connection of the disc 20, such as Figure 10 The schematic diagram of the structure is shown.

[0038] In order to further reduce the frictional force, convex arc points 34 are provided on the surface of the clutch block and the ...

PUM

Login to View More

Login to View More Abstract

Description

Claims

Application Information

Login to View More

Login to View More - R&D

- Intellectual Property

- Life Sciences

- Materials

- Tech Scout

- Unparalleled Data Quality

- Higher Quality Content

- 60% Fewer Hallucinations

Browse by: Latest US Patents, China's latest patents, Technical Efficacy Thesaurus, Application Domain, Technology Topic, Popular Technical Reports.

© 2025 PatSnap. All rights reserved.Legal|Privacy policy|Modern Slavery Act Transparency Statement|Sitemap|About US| Contact US: help@patsnap.com