Built-in screen type aerobic granular sludge reactor and sewage treatment method thereof

A technology of aerobic granular sludge and sewage treatment methods, applied in water/sludge/sewage treatment, biological water/sewage treatment, chemical instruments and methods, etc., can solve the problem of lack of effective particle size control strategies, hydraulic shearing Increased operating energy consumption, poor total nitrogen removal effect, etc., to achieve the effect of inhibiting excessive growth of particle size, high COD and total nitrogen removal rate, and small footprint

- Summary

- Abstract

- Description

- Claims

- Application Information

AI Technical Summary

Problems solved by technology

Method used

Image

Examples

Embodiment Construction

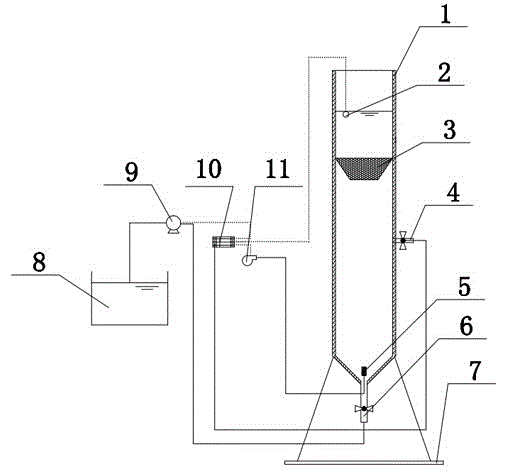

[0035] The present invention will be further described below in conjunction with the accompanying drawings of the description.

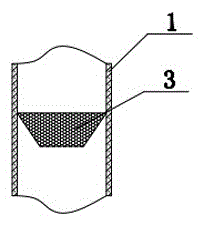

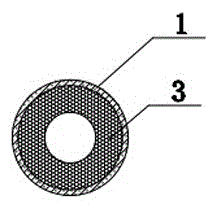

[0036]As shown in the figure, the built-in screen type aerobic granular sludge reactor includes a reactor main body 1 for inoculating aerobic granular sludge. The reactor main body 1 is a cylindrical structure, and the lower part of the reactor main body 1 is provided with water inlet Device 6, the middle part of the reactor main body 1 is provided with a water outlet device 4, the water inlet device 6 is connected to the water inlet pump 9 through the water inlet pipe, and the water inlet pump 9 is connected to the sewage distribution tank 8; it also includes a controller 10, which is controlled by the water inlet pump 9 connection, the ratio of the height of the reactor main body 1 to the inner diameter is 5-8:1, the bottom of the reactor main body 1 cavity is provided with an aeration device 5, the aeration device 5 is connected with the blower 11 ...

PUM

Login to View More

Login to View More Abstract

Description

Claims

Application Information

Login to View More

Login to View More - R&D

- Intellectual Property

- Life Sciences

- Materials

- Tech Scout

- Unparalleled Data Quality

- Higher Quality Content

- 60% Fewer Hallucinations

Browse by: Latest US Patents, China's latest patents, Technical Efficacy Thesaurus, Application Domain, Technology Topic, Popular Technical Reports.

© 2025 PatSnap. All rights reserved.Legal|Privacy policy|Modern Slavery Act Transparency Statement|Sitemap|About US| Contact US: help@patsnap.com