Cement grinding aid and using method thereof

A technology of cement grinding aid and reinforcing agent, applied in the field of cement adjuvant, can solve the problems of decreased pulverization efficiency, increased power consumption per unit of production, and increased tendency of fine particles to agglomerate and aggregate each other, so as to improve waterproofness and enhance cement strength. , the effect of reducing dust pollution

- Summary

- Abstract

- Description

- Claims

- Application Information

AI Technical Summary

Problems solved by technology

Method used

Image

Examples

Embodiment Construction

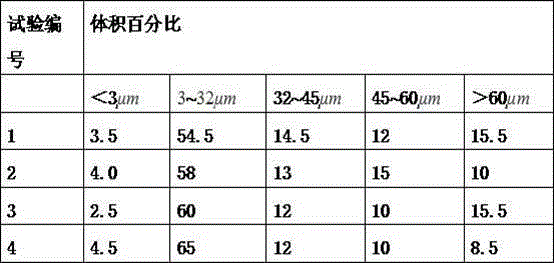

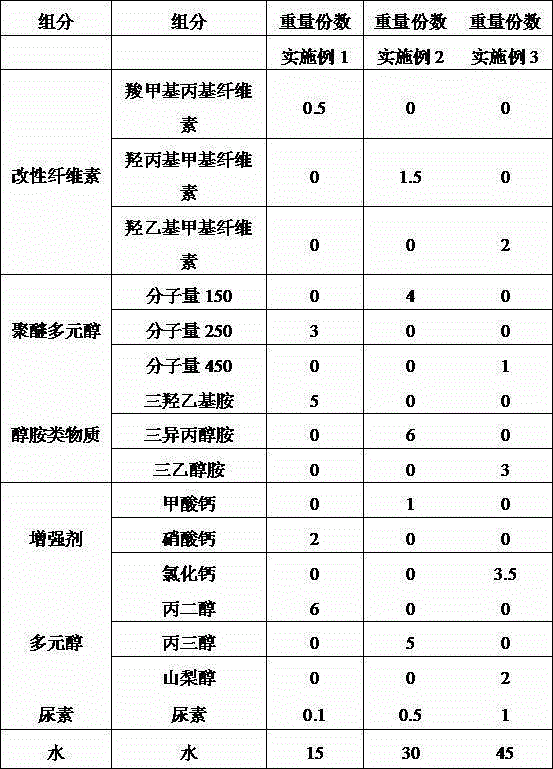

[0020] Below in conjunction with embodiment the present invention is described in detail, embodiment is only preferred embodiment of the present invention, is not limitation of the present invention, table 1 is the concrete embodiment 1,2,3 of cement grinding aid of the present invention.

[0021] Table I

[0022]

[0023] The preparation methods of the above examples are well known in the art and will not be described in detail here.

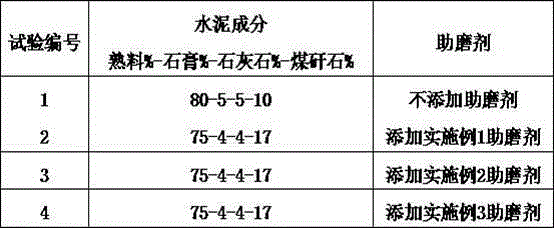

[0024] Add the cement grinding aids obtained in Examples 1, 2, and 3 to cement for performance testing. The amount of grinding aids added is 0.2%. The specific experimental parameters and concrete components of the cement are shown in Table 2

[0025] Table II

[0026]

PUM

Login to View More

Login to View More Abstract

Description

Claims

Application Information

Login to View More

Login to View More - R&D

- Intellectual Property

- Life Sciences

- Materials

- Tech Scout

- Unparalleled Data Quality

- Higher Quality Content

- 60% Fewer Hallucinations

Browse by: Latest US Patents, China's latest patents, Technical Efficacy Thesaurus, Application Domain, Technology Topic, Popular Technical Reports.

© 2025 PatSnap. All rights reserved.Legal|Privacy policy|Modern Slavery Act Transparency Statement|Sitemap|About US| Contact US: help@patsnap.com