A kind of preparation method of high workability recycled concrete

A technology of recycled concrete and work performance, which is applied in the field of housing construction materials, can solve the problems of lack of improvement in the workability of recycled concrete, recycled concrete and recycled concrete, and achieve the effects of promoting commercial application, improving construction performance, and reducing losses

- Summary

- Abstract

- Description

- Claims

- Application Information

AI Technical Summary

Problems solved by technology

Method used

Image

Examples

Embodiment 1

[0109] First weigh the cementitious material, and take 15-25% of fly ash, 25-40% of slag powder, and 40-60% of cement respectively in terms of weight percentage, wherein the total amount of fly ash and slag powder is not more than that of the cementitious material 60% of the total usage. Add the cementitious material to the concrete mixer and mix well. The natural yellow sand is then weighed, and its sand rate is adjusted according to the actual slump of recycled concrete less than 10mm, 10-60mm, and greater than 60mm. Then add the natural yellow sand into the concrete mixer, mix it with the cementitious material, and mix well. Then, add the natural coarse aggregate and the recycled coarse aggregate to the concrete mixer at a mass ratio of 1:1, continue stirring with the cementitious material and natural yellow sand, and mix evenly to obtain a dry material. Among them, the particle size of the natural coarse aggregate is not greater than 25mm, and the particle size of the re...

Embodiment 2

[0113] The recycled concrete was prepared according to the method steps in Example 1, wherein, starting from the engineering application, the selected recycled concrete mix ratio was the mix ratio for the production of a mixing station. The strength grade is C30, and the initial slump is 180±10mm. At the same time, no slump retaining agent is added to the recycled concrete, and only saponin is added.

[0114] In order to quantitatively study the effect of saponin content on improving the workability of recycled concrete, the substitution rate For the test groups of 0% and 100%, three dosages of 0.3‰, 0.6‰ and 1.2‰ (the amount of saponin is taken according to the ratio of the mass of the gelling material) were used for the test. The test mix ratio is shown in Table 5.

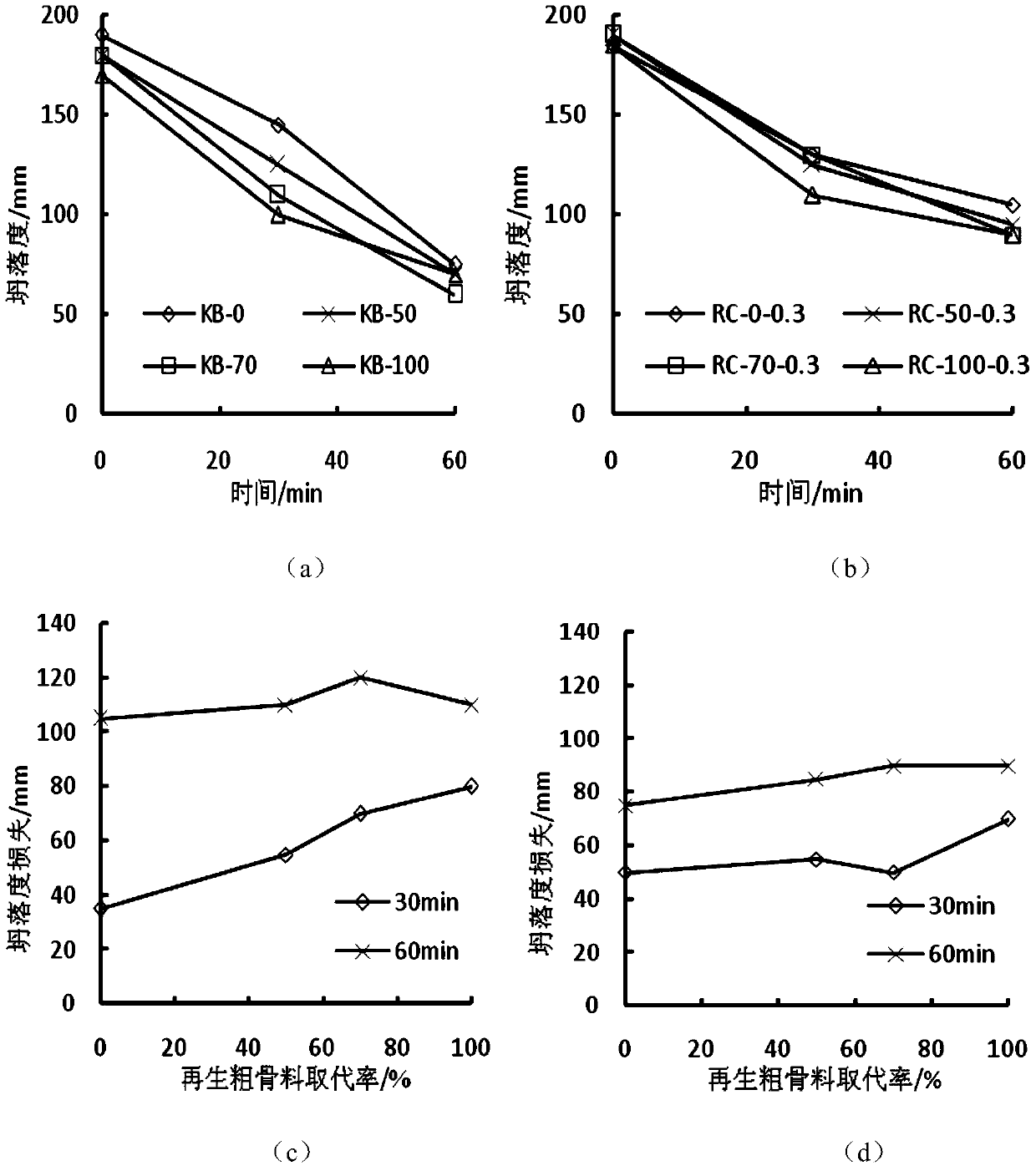

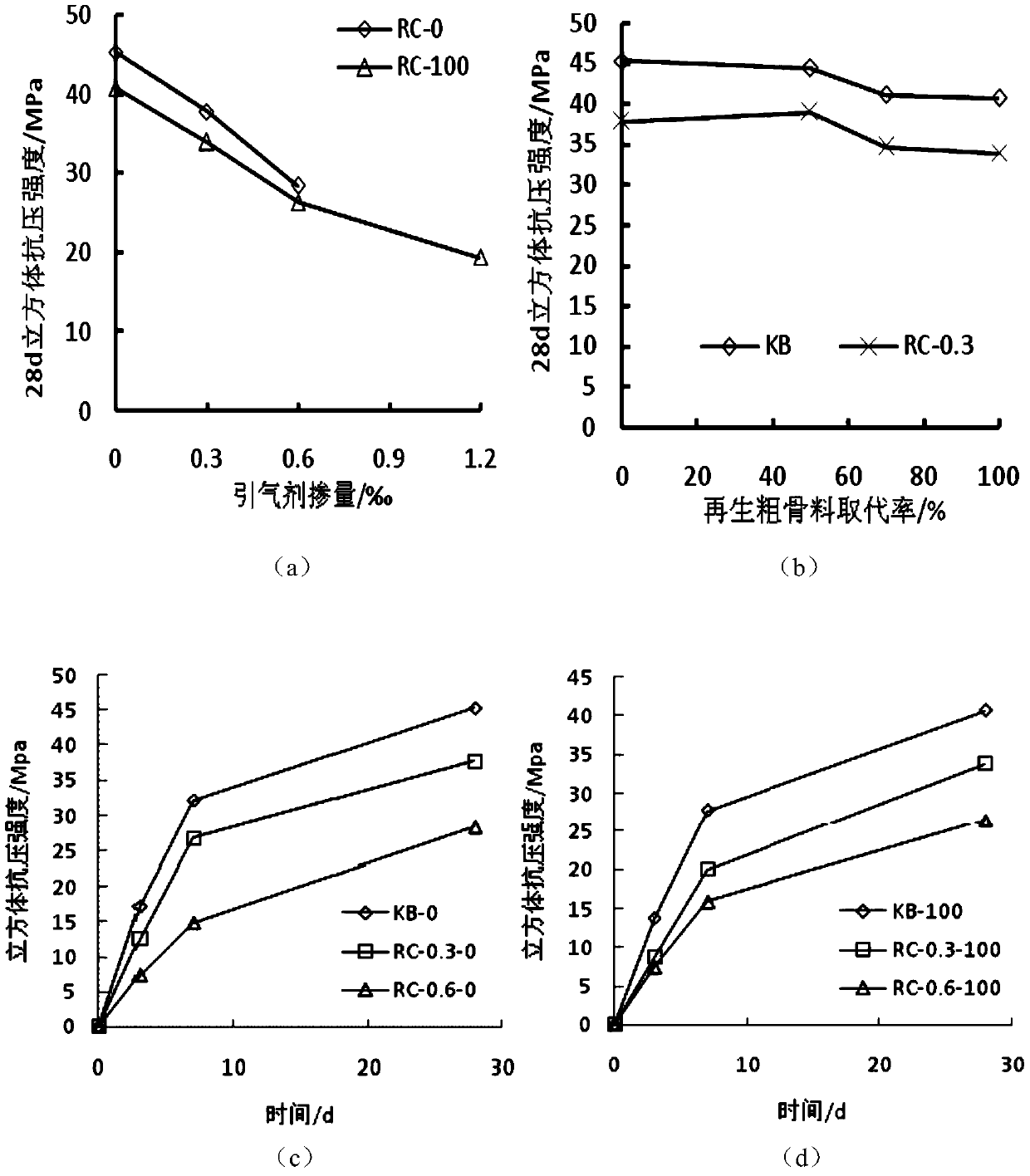

[0115] The ratio of recycled coarse aggregate to replace natural coarse aggregate will have different effects on the performance of recycled concrete. In order to study the effect of the replacement rate of re...

Embodiment 3

[0120] 1. Workability test results

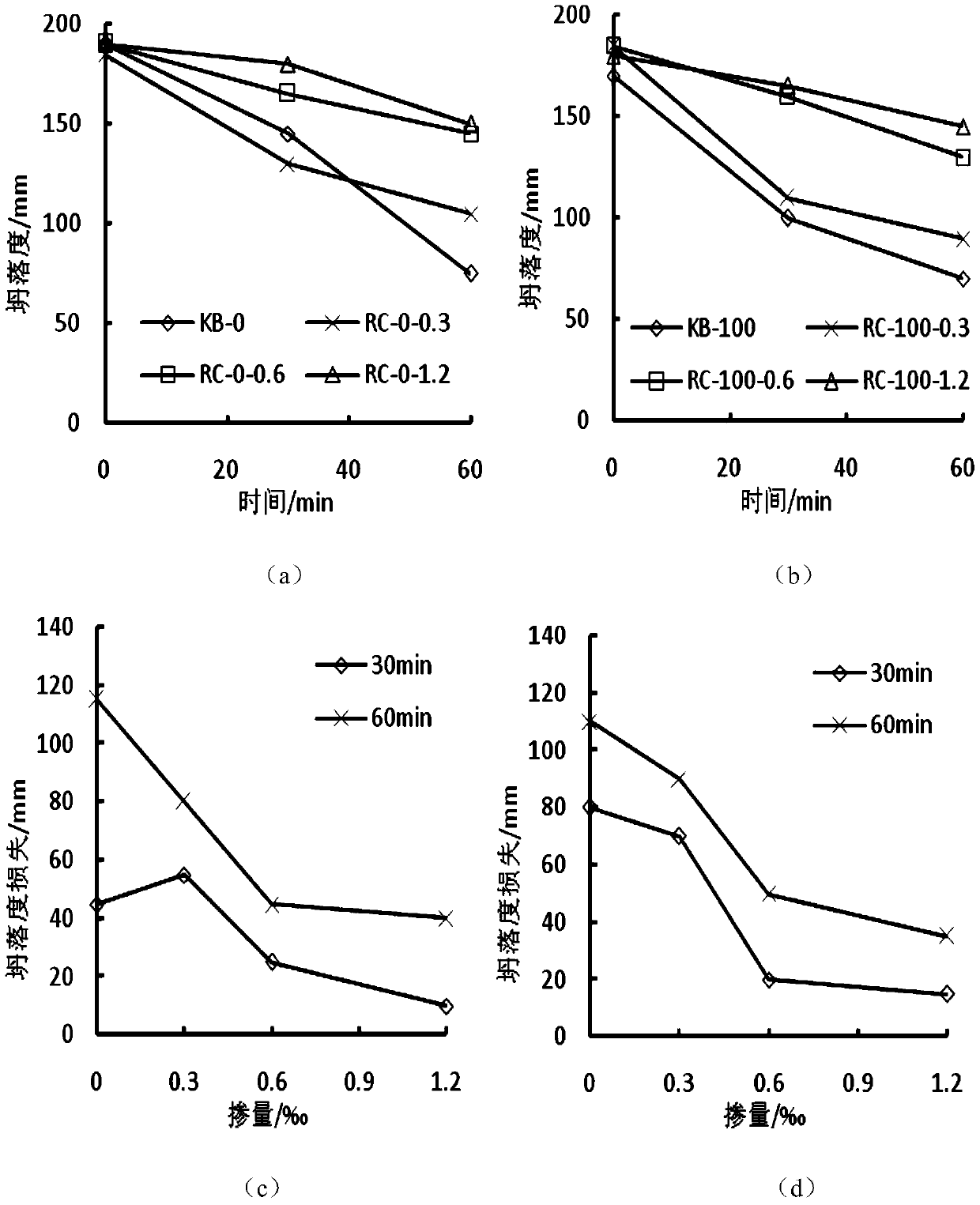

[0121] The working performance of the recycled concrete prepared with the mix ratio shown in Table 5 in the above-mentioned Example 2 was measured, and the main method was to measure and compare the loss of slump within a certain period of time.

[0122] The hourly slump loss of each test group measured in this example is generally larger than the actual hourly slump loss value of commercial concrete in the project. The reason for the analysis is that the commercial concrete in the project is in a state of constant stirring during transportation, and the concrete used to measure the subsequent slump loss in the test is in a static state because the conditions in the project cannot be simulated. However, this test can still analyze the effect of saponin on the slump loss of recycled concrete by comparing with the blank group.

[0123] This test is to study the change of the workability of recycled concrete over time. The initial slump of th...

PUM

| Property | Measurement | Unit |

|---|---|---|

| particle diameter | aaaaa | aaaaa |

| particle diameter | aaaaa | aaaaa |

| particle diameter | aaaaa | aaaaa |

Abstract

Description

Claims

Application Information

Login to View More

Login to View More - R&D

- Intellectual Property

- Life Sciences

- Materials

- Tech Scout

- Unparalleled Data Quality

- Higher Quality Content

- 60% Fewer Hallucinations

Browse by: Latest US Patents, China's latest patents, Technical Efficacy Thesaurus, Application Domain, Technology Topic, Popular Technical Reports.

© 2025 PatSnap. All rights reserved.Legal|Privacy policy|Modern Slavery Act Transparency Statement|Sitemap|About US| Contact US: help@patsnap.com