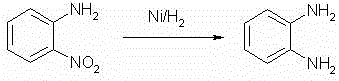

A kind of green synthetic method of reducing o-nitroaniline to prepare o-phenylenediamine

A technology of o-nitroaniline and o-phenylenediamine, which is applied in the field of synthesis of o-phenylenediamine, can solve the problems of difficulty in large-scale production, short catalyst deactivation time, and difficult catalyst recovery, and achieve green production and Emissions, suitable for large-scale production and promotion, and environmentally friendly effects

- Summary

- Abstract

- Description

- Claims

- Application Information

AI Technical Summary

Problems solved by technology

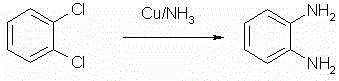

Method used

Image

Examples

Embodiment 1

[0029] Add 1mol o-nitroaniline, 3g of the above-mentioned supported catalyst (Ni, Se, Fe / C catalyst), 500mL of water and 100mL of ethanol into a stainless steel autoclave with a capacity of 1000mL, set the temperature in the autoclave to 30°C, and then After the air in the autoclave was replaced, 0.5 MPa carbon monoxide was introduced, and the reaction was stirred for 10 hours. The conversion rate of o-phenylenediamine was 99.8% as detected by gas chromatography.

[0030] In this example, o-phenylenediamine is prepared by reduction, with mild reaction conditions, high product yield, long-lasting catalyst activity, high reaction selectivity, less catalyst consumption, easy separation of product and catalyst, and convenient recycling.

Embodiment 2

[0032] Add 1mol o-nitroaniline, 2.5g supported catalyst (Pt, Se, Fe / C catalyst), 500mL water into a stainless steel autoclave with a capacity of 1000mL, set the temperature inside the autoclave to 50°C, and then replace the autoclave with carbon monoxide After neutralizing the air, 0.7MPa carbon monoxide was introduced, and the reaction was stirred for 10 hours. The conversion rate of o-phenylenediamine was 98% as detected by gas chromatography.

[0033] In this example, the preparation of o-phenylenediamine by reduction has mild reaction conditions, high product yield, no pollution, long-lasting catalyst activity, less catalyst consumption, easy separation of product and catalyst, easy recovery and recycling, light treatment of three wastes, and can meet the requirements of cleaning production requirements.

Embodiment 3

[0035] Add 1mol of o-nitroaniline, 3g of supported catalyst (Pt, Se, Ni / C catalyst), 500mL of water and 80mL of acetone into a stainless steel autoclave with a capacity of 1000mL, set the temperature in the autoclave to 100°C, and then replace it with carbon monoxide After the air in the autoclave, 0.5MPa carbon monoxide was introduced, and the reaction was stirred for 10 hours. The conversion rate of o-phenylenediamine was 99.5% as detected by gas chromatography.

[0036] In this example, the preparation of o-phenylenediamine by reduction has mild reaction conditions, high product yield, no pollution, long-lasting catalyst activity, less catalyst consumption, easy separation of product and catalyst, easy recovery and recycling, light treatment of three wastes, and can meet the requirements of cleaning production requirements.

PUM

| Property | Measurement | Unit |

|---|---|---|

| particle size | aaaaa | aaaaa |

| size | aaaaa | aaaaa |

Abstract

Description

Claims

Application Information

Login to View More

Login to View More - R&D

- Intellectual Property

- Life Sciences

- Materials

- Tech Scout

- Unparalleled Data Quality

- Higher Quality Content

- 60% Fewer Hallucinations

Browse by: Latest US Patents, China's latest patents, Technical Efficacy Thesaurus, Application Domain, Technology Topic, Popular Technical Reports.

© 2025 PatSnap. All rights reserved.Legal|Privacy policy|Modern Slavery Act Transparency Statement|Sitemap|About US| Contact US: help@patsnap.com