Preparation method of high-efficiency high-temperature acidizing slow-released agent

A slow-release and high-temperature technology, which is applied in the field of preparation of high-efficiency high-temperature acidified slow-release agents, can solve the problem that the product does not have hydrophilic properties, and achieve the effect of good interfacial activity and small dosage.

- Summary

- Abstract

- Description

- Claims

- Application Information

AI Technical Summary

Problems solved by technology

Method used

Image

Examples

Embodiment 1

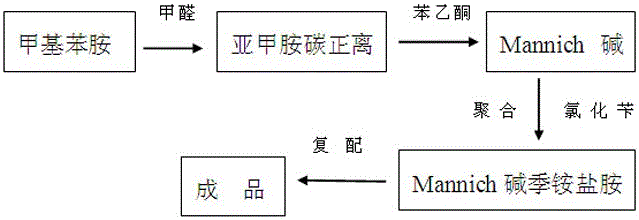

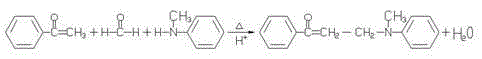

[0020] Embodiment 1: the preparation method of a kind of high-efficiency high-temperature acidification slow-release agent mentioned in the present invention, comprises the following steps:

[0021] (1) Add 524kg of methylaniline and 435kg of formaldehyde into the reaction kettle, add 18kg of concentrated sulfuric acid dropwise, control the temperature at 80-90°C, and continue the reaction for 2 hours.

[0022] (2) Put 520kg of acetophenone into the reaction kettle, heat up and vacuum dehydrate after adding, until the temperature reaches 130-140°C, and there is no more water.

[0023] (3) Continue to heat up to 180°C, keep the temperature for 8 hours, and cool down to 70-80°C.

[0024] (4) Slowly add 770 kg of benzyl chloride dropwise to the reaction kettle to continue the reaction. After the dropwise addition of benzyl chloride is completed, keep the temperature at 80°C and continue the reaction for 2 hours.

[0025] (5) After the reaction is completed, pump 500kg of organic...

Embodiment 2

[0032] Embodiment 2: the preparation method of a kind of high-efficiency high-temperature acidification slow-release agent mentioned in the present invention, comprises the following steps:

[0033] (1) Add 524kg of methylaniline and 435kg of formaldehyde into the reaction kettle, add 25kg of concentrated sulfuric acid dropwise, control the temperature at 80-90°C, and continue the reaction for 2 hours.

[0034] (2) Put 550kg of acetophenone into the reaction kettle, heat up and vacuum dehydrate after adding, until the temperature reaches 130-140°C, and there is no more water.

[0035] (3) Continue to heat up to 180°C, keep the temperature for 8 hours, and cool down to 70-80°C.

[0036] (4) Slowly add 600 kg of benzyl chloride dropwise to the reaction kettle to continue the reaction, and after the addition of benzyl chloride is completed, keep the temperature at 80°C and continue the reaction for 2 hours.

[0037] (5) After the reaction is completed, pump 500kg of organic solv...

Embodiment 3

[0038] Embodiment 3: the preparation method of a kind of high-efficiency high-temperature acidification sustained-release agent mentioned in the present invention, comprises the following steps:

[0039] (1) Add 500kg of methylaniline and 450kg of formaldehyde into the reaction kettle, add 30kg of concentrated sulfuric acid dropwise, control the temperature at 80-90°C, and continue the reaction for 2 hours.

[0040] (2) Put 550kg of acetophenone into the reaction kettle, heat up and vacuum dehydrate after adding, until the temperature reaches 130-140°C, and there is no more water.

[0041] (3) Continue to heat up to 180°C, keep the temperature for 8 hours, and cool down to 70-80°C.

[0042] (4) Slowly add 550 kg of benzyl chloride dropwise to the reaction kettle to continue the reaction. After the dropwise addition of benzyl chloride is completed, keep the temperature at 80°C and continue the reaction for 2 hours.

[0043] (5) After the reaction is completed, pump 500kg of or...

PUM

Login to View More

Login to View More Abstract

Description

Claims

Application Information

Login to View More

Login to View More - R&D

- Intellectual Property

- Life Sciences

- Materials

- Tech Scout

- Unparalleled Data Quality

- Higher Quality Content

- 60% Fewer Hallucinations

Browse by: Latest US Patents, China's latest patents, Technical Efficacy Thesaurus, Application Domain, Technology Topic, Popular Technical Reports.

© 2025 PatSnap. All rights reserved.Legal|Privacy policy|Modern Slavery Act Transparency Statement|Sitemap|About US| Contact US: help@patsnap.com