Metal cleaner and application thereof

A technology of metal cleaning agent and acid cleaning agent, which is applied in the field of cleaning agents, can solve problems such as consumer loss, raw materials not environmentally friendly, shutdown, etc., and achieve the effects of stable performance, guaranteed corrosion inhibition, and uniform performance

- Summary

- Abstract

- Description

- Claims

- Application Information

AI Technical Summary

Problems solved by technology

Method used

Image

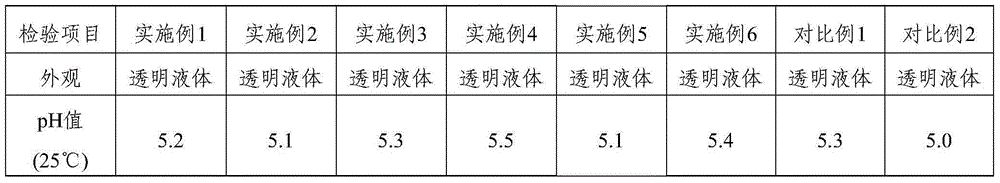

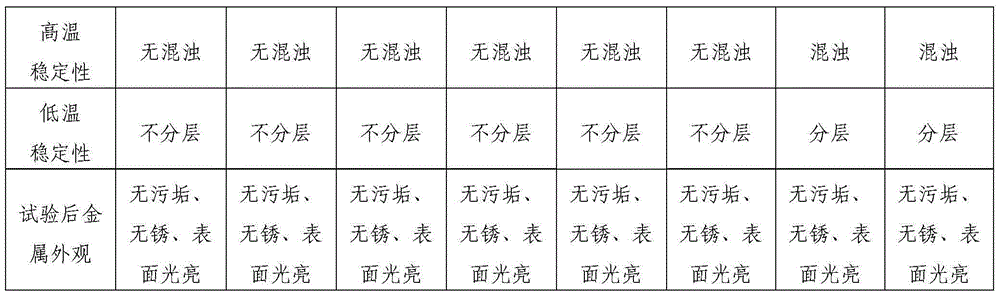

Examples

Embodiment 1

[0028] The composition of the metal cleaning agent is: 0.5 kg of silicon tetrafluoride, 0.5 kg of methanesulfonic acid, 0.1 kg of imidazoline sebacate, 0.01 kg of isothiazolinone, 0.01 kg of lactic acid, 3 kg of D-limonene, and 80 kg of deionized water.

Embodiment 2

[0030] The composition of the metal cleaning agent is: 0.7kg of silicon tetrafluoride, 0.5kg of methanesulfonic acid, 0.5kg of imidazoline sebacate, 0.01kg of isothiazolinone, 0.01kg of lactic acid, 3kg of D-limonene, and 120kg of deionized water.

Embodiment 3

[0032] The composition of metal cleaning agent is: silicon tetrafluoride 1kg, ethanesulfonic acid 1kg, imidazoline sebacate 0.1kg, benzisothiazolinone 0.05kg, lactic acid 0.03kg, D-limonene 10kg, deionized water 80kg .

PUM

Login to View More

Login to View More Abstract

Description

Claims

Application Information

Login to View More

Login to View More - R&D

- Intellectual Property

- Life Sciences

- Materials

- Tech Scout

- Unparalleled Data Quality

- Higher Quality Content

- 60% Fewer Hallucinations

Browse by: Latest US Patents, China's latest patents, Technical Efficacy Thesaurus, Application Domain, Technology Topic, Popular Technical Reports.

© 2025 PatSnap. All rights reserved.Legal|Privacy policy|Modern Slavery Act Transparency Statement|Sitemap|About US| Contact US: help@patsnap.com