Embedded frame track plate and track structure comprising same

A technology of embedded frame and embedded track, applied in the superstructure of the track, track, road, etc., can solve the problems of temperature sensitivity, human harm, rail wear and so on

- Summary

- Abstract

- Description

- Claims

- Application Information

AI Technical Summary

Problems solved by technology

Method used

Image

Examples

Embodiment 1

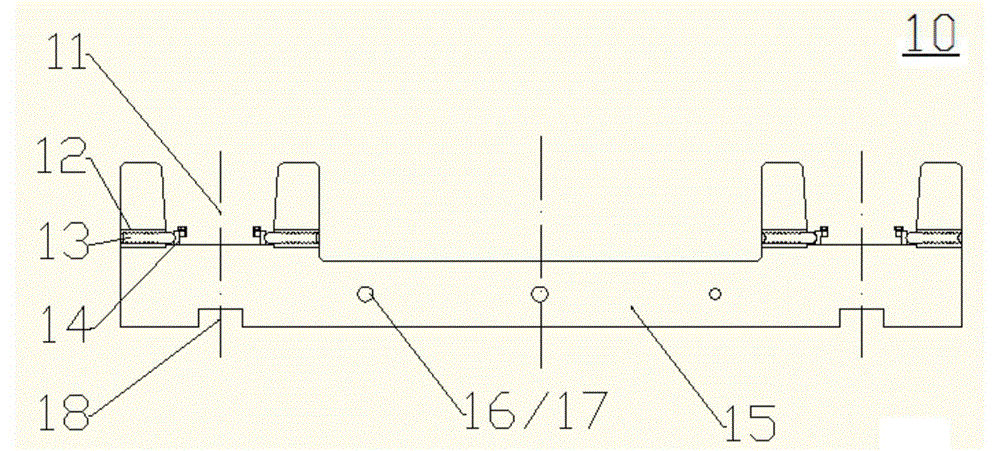

[0067] figure 1 Front view of the embedded frame track slab.

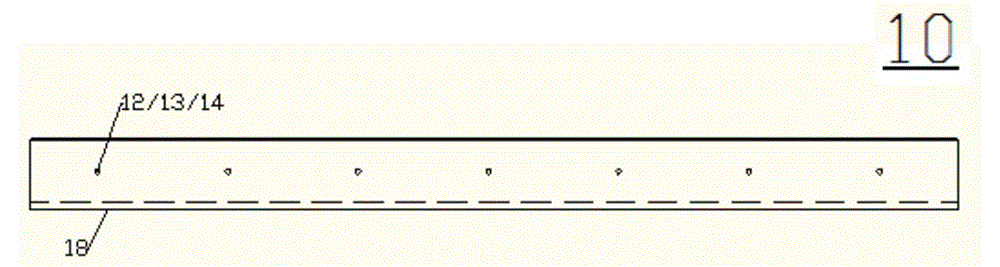

[0068] figure 2 Left view for embedded frame track slab.

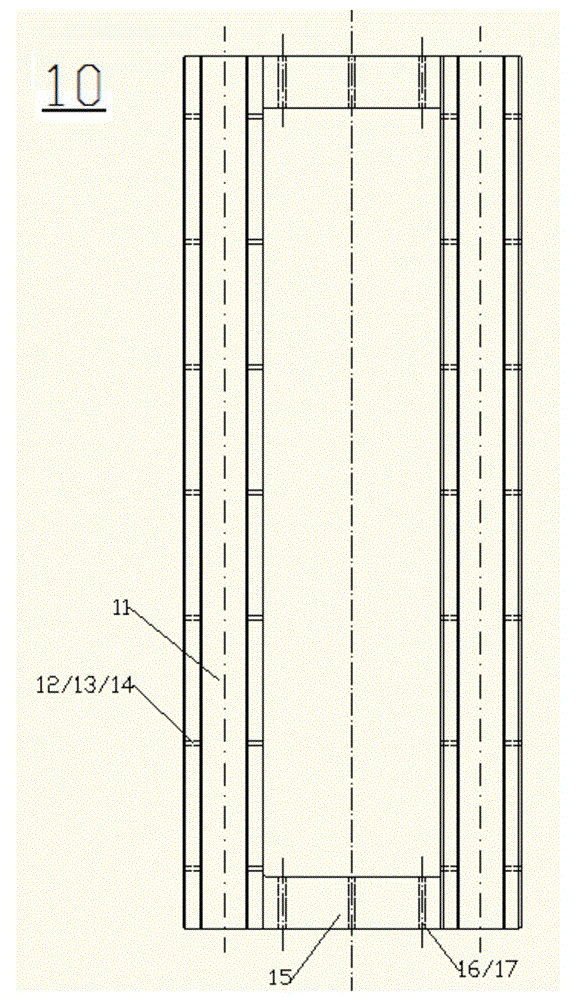

[0069] image 3 A top view of the embedded frame track slab.

[0070] Such as figure 1 , figure 2 and image 3 As shown, the embedded frame track plate 10 includes: two symmetrically arranged rail bearing grooves 11, rail bearing groove sleeves 12, gauge adjustment bolts 13, rail compression stoppers 14, connecting beams 15, longitudinal anchors Tube 16, longitudinal connecting screw 17 and floor groove 18.

[0071] The rail bearing groove 11 is used to place the steel rail 20, and several rail bearing groove sleeves 12 are arranged symmetrically on both sides of the rail bearing groove 11. Each rail bearing groove sleeve 12 has a gauge adjusting bolt 13 inside, and the rail gauge adjusting bolt 13 A rail compression limiter 14 is arranged between the bolt 13 and the rail 20 . The embedded track slab supports mechanically adjusting and restrictin...

Embodiment 2

[0120] Figure 18 It is a schematic diagram of the embedded track structure on the tram bridge in Embodiment 2.

[0121] Such as Figure 18 Shown is the embedded track structure on the tram bridge. The construction method and procedure are the same as Example 1. The difference is that the construction of the base needs to plant bars on the bridge deck, and the construction of the protective fence needs to be bonded with epoxy resin mortar, etc. Adhesive construction on the bridge deck.

[0122] Variation 2

[0123] Figure 19 It is a schematic diagram of the embedded track structure of the tram embankment section in Modification 2.

[0124] Such as Figure 19 Shown is the embedded track structure of the tram embankment section, and the construction method and procedure are the same as the first example.

Embodiment 3

[0126] Figure 20 It is a schematic diagram of the subway tunnel embedded track structure in Embodiment 3.

[0127] Such as Figure 20 Shown is the embedded track structure of the subway tunnel, the construction method and procedure are the same as the first example, and the base construction method is the same as the second example. The difference lies in that the outer dimension of the track slab is slightly changed, the center of the track bed should be a prefabricated flat plate 103, and the filling of sand and gravel in the track bed is cancelled.

PUM

| Property | Measurement | Unit |

|---|---|---|

| Roughness | aaaaa | aaaaa |

Abstract

Description

Claims

Application Information

Login to View More

Login to View More - R&D

- Intellectual Property

- Life Sciences

- Materials

- Tech Scout

- Unparalleled Data Quality

- Higher Quality Content

- 60% Fewer Hallucinations

Browse by: Latest US Patents, China's latest patents, Technical Efficacy Thesaurus, Application Domain, Technology Topic, Popular Technical Reports.

© 2025 PatSnap. All rights reserved.Legal|Privacy policy|Modern Slavery Act Transparency Statement|Sitemap|About US| Contact US: help@patsnap.com