Route inspection maintenance equipment for sound barrier

A technology for maintenance equipment and sound barriers, which is applied in the field of sound barrier inspection and maintenance equipment, can solve the problems of complex operation, high operation cost, low work efficiency, etc., and achieves the effects of safe and fast operation, good observation effect and low labor intensity.

- Summary

- Abstract

- Description

- Claims

- Application Information

AI Technical Summary

Problems solved by technology

Method used

Image

Examples

Embodiment Construction

[0032] The present invention will be described in further detail below in conjunction with the accompanying drawings and embodiments.

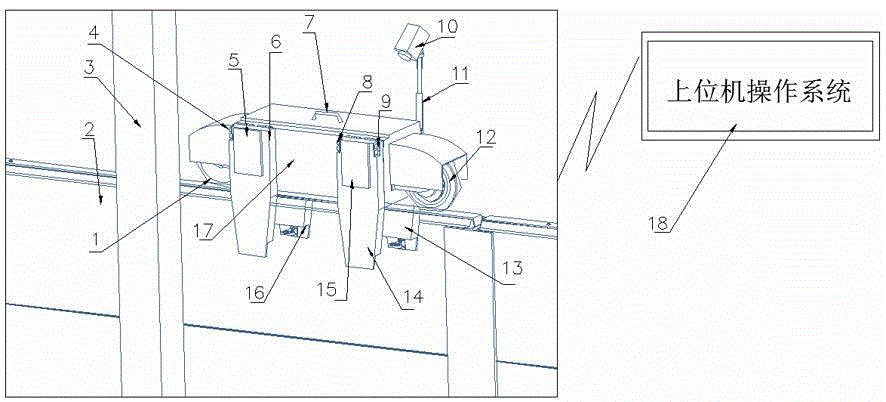

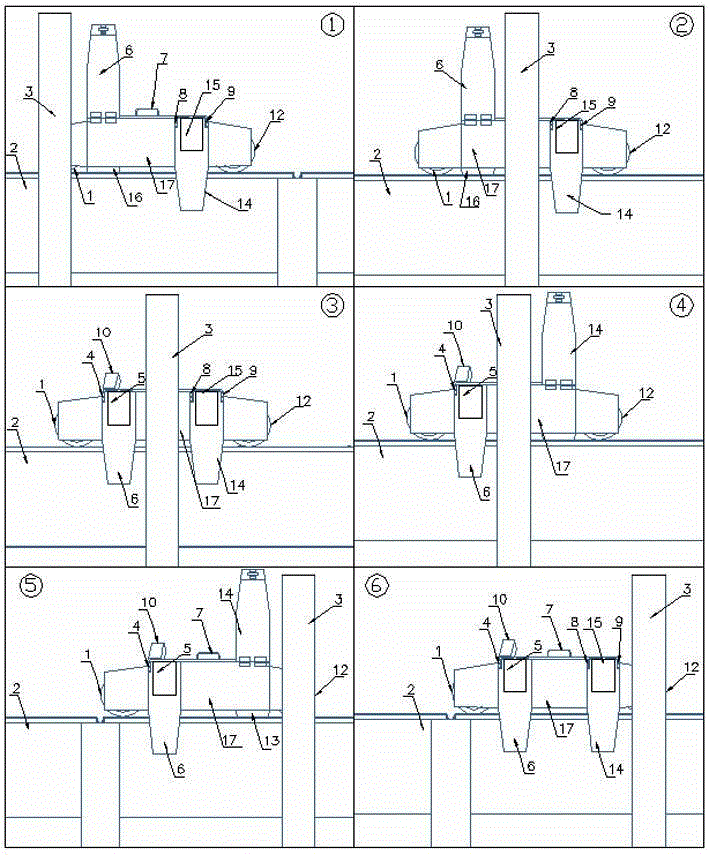

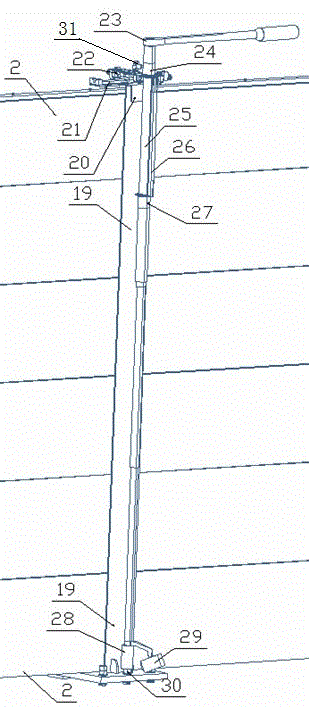

[0033] A sound barrier inspection and maintenance equipment, including a split inspection trolley and a maintenance device; such as figure 1 As shown, the inspection trolley is provided with a row of wheels in the direction of the sound barrier 2 (in this embodiment, the front and rear wheels 1 and 12 are respectively arranged at the front and rear ends of the inspection trolley, wherein the front wheel 1 is the driving wheel) 1. Two limit plates are respectively arranged on both sides of the sound barrier 2, and the two limit plates located on the inner side of the sound barrier 2 are equipped with detectors capable of judging whether there is an obstacle and can be flipped around the axis to the vehicle body 17, the inspection trolley is also provided with a first video module 10, and in this embodiment, the inspection trolley is also provid...

PUM

Login to view more

Login to view more Abstract

Description

Claims

Application Information

Login to view more

Login to view more - R&D Engineer

- R&D Manager

- IP Professional

- Industry Leading Data Capabilities

- Powerful AI technology

- Patent DNA Extraction

Browse by: Latest US Patents, China's latest patents, Technical Efficacy Thesaurus, Application Domain, Technology Topic.

© 2024 PatSnap. All rights reserved.Legal|Privacy policy|Modern Slavery Act Transparency Statement|Sitemap