Gravity type speed-limiting down-sliding material transferring method and apparatus

A transfer device, gravity-based technology, applied in building construction, building material processing, construction, etc., can solve problems such as energy consumption, increase processing capacity, improve construction efficiency, and facilitate assembly and disassembly.

- Summary

- Abstract

- Description

- Claims

- Application Information

AI Technical Summary

Problems solved by technology

Method used

Image

Examples

Embodiment 1

[0051] A gravity-type speed-limited sliding material transfer method is to make the material slide down at a limited speed in an S-shaped trajectory under the action of gravity.

Embodiment 2

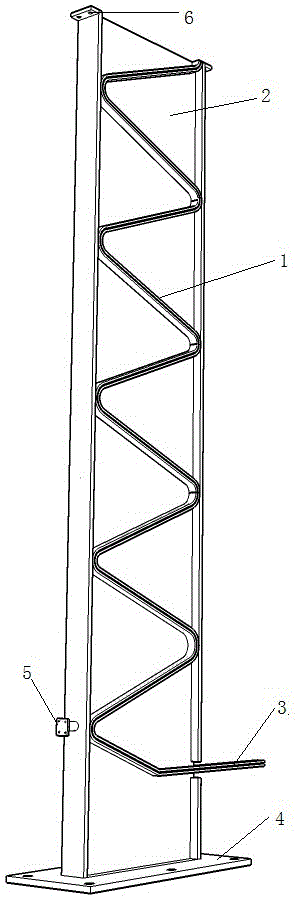

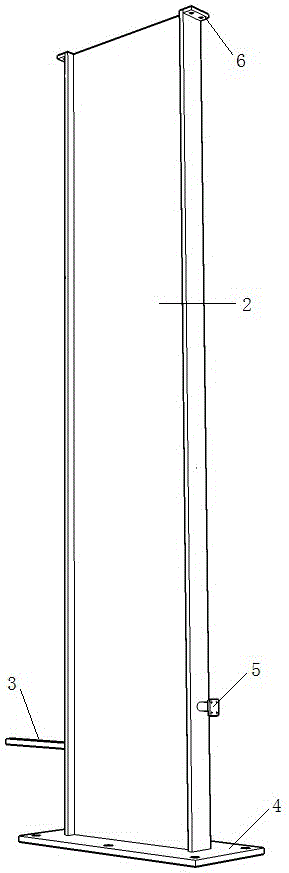

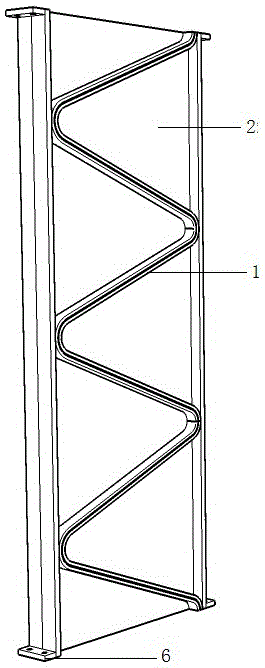

[0053] Such as Figure 1-14 As shown, a material transfer device for gravity-type speed-limited tobogganing includes a base section 25, a straight section 26, a station section 27 and a material delivery vehicle. Among them: the base section 25 is used to be fixed on the ground to realize the structural load of the whole device and is used for material removal; the straight section 26 is used for the downlink of materials; the station layer section 27 is used for loading or removing materials on floors; material delivery The cart is used to carry the materials on the floor to the lower floor or the ground. The base section 25, the straight section 26 and the station floor section 27 are all provided with S-shaped guide rails 1; the S-shaped guide rails 1 are formed by connecting end to end of a plurality of ∫-type short guide rails, and the ∫-type short guide rails are straight rails with two ends. The short arc makes the end-to-end connection form an arc track.

[0054] Bas...

Embodiment 3

[0064] Such as Figure 16 and 17 As shown, the difference between embodiment 3 and embodiment 2 is that embodiment 3 is a material transfer device for gravity-type speed-limited tobogganing of a thickened type, and the specific difference is that the box plate 2 includes two opposite half-shaped grooves 23 And a central structure 24, this central structure is a word-shaped profile.

PUM

Login to View More

Login to View More Abstract

Description

Claims

Application Information

Login to View More

Login to View More - R&D

- Intellectual Property

- Life Sciences

- Materials

- Tech Scout

- Unparalleled Data Quality

- Higher Quality Content

- 60% Fewer Hallucinations

Browse by: Latest US Patents, China's latest patents, Technical Efficacy Thesaurus, Application Domain, Technology Topic, Popular Technical Reports.

© 2025 PatSnap. All rights reserved.Legal|Privacy policy|Modern Slavery Act Transparency Statement|Sitemap|About US| Contact US: help@patsnap.com