Horizontally-opposite diaphragm type electric vacuum pump

An electric vacuum pump, horizontally opposed technology, applied in the direction of variable capacity pump components, pumps, pump components, etc., can solve the problems of increased volume and relatively high requirements for parts size, and achieves reduction in volume, reduction of ineffective residues, and structure. Simple and compact effect

- Summary

- Abstract

- Description

- Claims

- Application Information

AI Technical Summary

Problems solved by technology

Method used

Image

Examples

Embodiment Construction

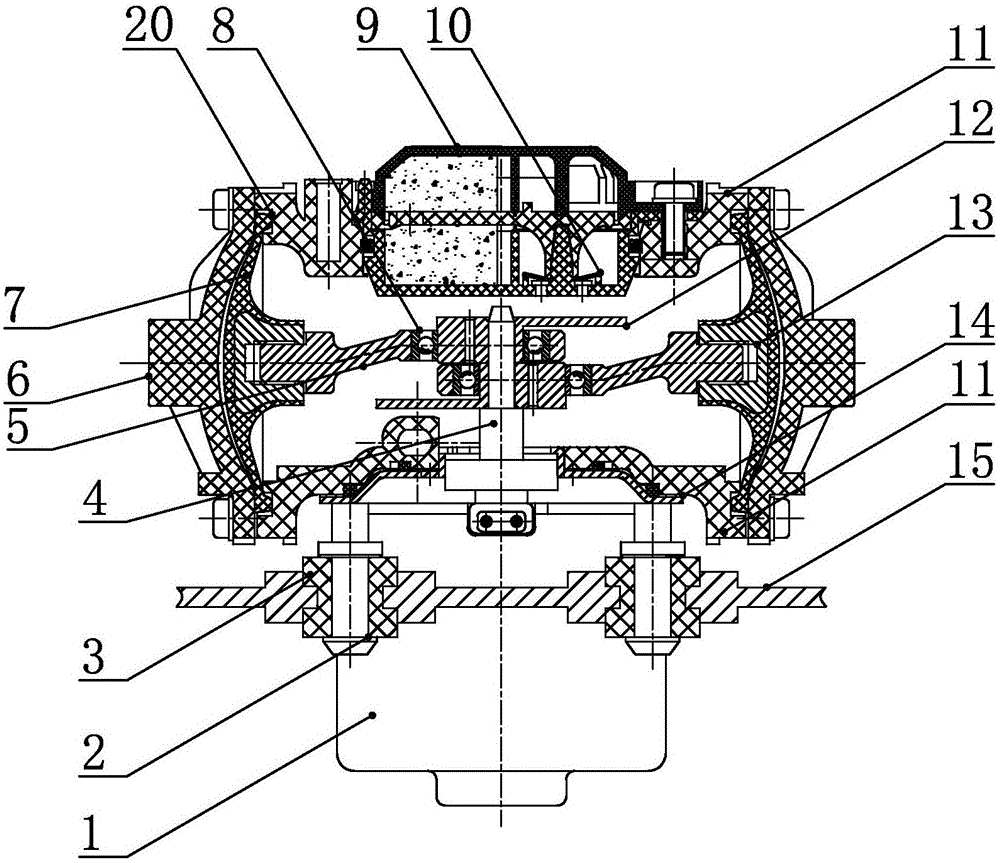

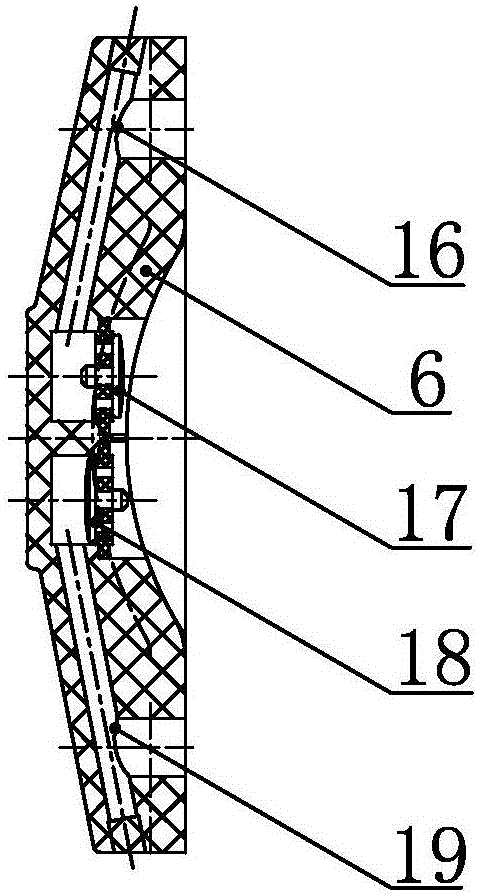

[0013] Such as figure 1 As shown, a horizontally opposed diaphragm type electric vacuum pump of the present invention includes a pump body 11 and a fixed bracket 15. A motor 1 is installed on the fixed bracket 15 through a motor fixing screw 2. Vibration rubber 3 is used to enhance the anti-seismic performance of the device. The motor 1 is a DC motor, which is directly powered by the battery of the car. The motor side cover 14 on the top of the motor 1 is connected to the bottom of the pump body 11 through bolts, and the bottom of the pump body 11 is provided with a through hole. The motor shaft 4 extends into the inside of the pump body 11 through the through hole, and two left and right horizontally opposite eccentric cranks 12 are installed on the motor shaft 4 . A connecting rod 5 is movably connected to the eccentric crank 12 , and a bearing 8 is arranged at the joint. The other end of the connecting rod 5 is connected to a diaphragm assembly 13 , and the diaphragm asse...

PUM

Login to View More

Login to View More Abstract

Description

Claims

Application Information

Login to View More

Login to View More - R&D

- Intellectual Property

- Life Sciences

- Materials

- Tech Scout

- Unparalleled Data Quality

- Higher Quality Content

- 60% Fewer Hallucinations

Browse by: Latest US Patents, China's latest patents, Technical Efficacy Thesaurus, Application Domain, Technology Topic, Popular Technical Reports.

© 2025 PatSnap. All rights reserved.Legal|Privacy policy|Modern Slavery Act Transparency Statement|Sitemap|About US| Contact US: help@patsnap.com