A piezoelectric active vibration isolation mechanism and its method for reducing the natural frequency of the vibration system

A technology of vibration system and natural frequency, which is applied in the direction of control/regulation system, non-rotational vibration suppression, non-electric variable control, etc. It can solve the problems of attenuating low-frequency interference, high structural natural frequency, and high rigidity of piezoelectric ceramics, etc., to achieve suppression Low-frequency interference, expanded usage scenarios, and high attenuation effects

- Summary

- Abstract

- Description

- Claims

- Application Information

AI Technical Summary

Problems solved by technology

Method used

Image

Examples

Embodiment 1

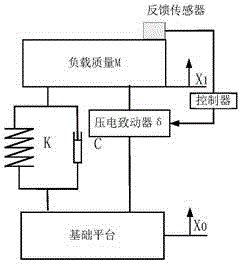

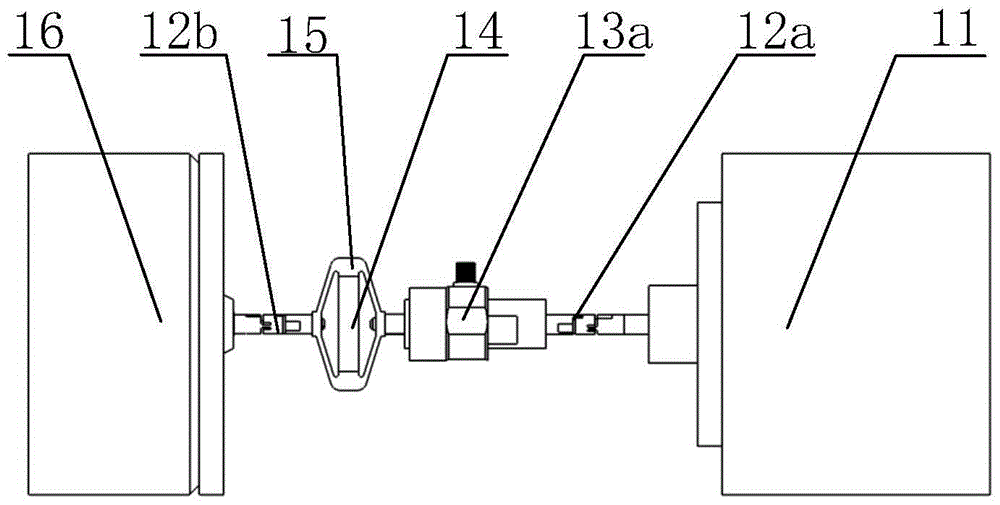

[0037] Referring to Figure 1(a), figure 2 And Fig. 3 (a), a kind of piezoelectric active vibration isolation mechanism, comprises first flexible hinge 12b, piezoelectric actuator, force sensor 13a, second flexible hinge 12a and controller, one end of described first flexible hinge 12b For connecting the base platform 16, the other end of which is sequentially connected to the piezoelectric actuator, the force sensor 13a and the second flexible hinge 12a, and the other end of the second flexible hinge 12a is used to connect to the load platform 11;

[0038] Both the piezoelectric actuator and the force sensor 13a are connected to the controller;

[0039] The force sensor 13a is used to detect the vibration signal of the load platform 11, and transmit the vibration signal to the controller, and the controller adopts the PI feedback control method to control the piezoelectric actuator to apply force on the load platform 11, thereby exerting force on the load platform 11. perform...

Embodiment 2

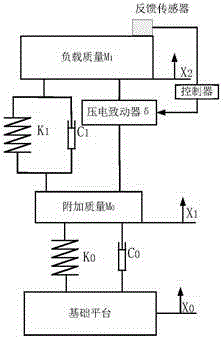

[0057] A piezoelectric active vibration isolation mechanism, including a first force sensor 23b, a spring bellows 27, an intermediate mass 26, a first flexible hinge 22b, a piezoelectric actuator, a second force sensor 23a, a second flexible hinge 22a and a control device, among them,

[0058] One end of the first force sensor 23b is used to connect to the base platform 28, and the other end is sequentially connected to the second force sensor 23b, the spring bellows 27, the intermediate mass 26, the first flexible hinge 22b, the piezoelectric actuator, A second force sensor 23a, a second flexible hinge 22a, the other end of the second flexible hinge 22a is used to connect to the load platform 21;

[0059] The first force sensor 23b, the piezoelectric actuator and the second force sensor 23a are all connected to the controller;

[0060] The first pressure sensor 23b and the second pressure sensor 23a are used to detect the vibration signals of the base platform 28 and the loa...

PUM

Login to View More

Login to View More Abstract

Description

Claims

Application Information

Login to View More

Login to View More - R&D

- Intellectual Property

- Life Sciences

- Materials

- Tech Scout

- Unparalleled Data Quality

- Higher Quality Content

- 60% Fewer Hallucinations

Browse by: Latest US Patents, China's latest patents, Technical Efficacy Thesaurus, Application Domain, Technology Topic, Popular Technical Reports.

© 2025 PatSnap. All rights reserved.Legal|Privacy policy|Modern Slavery Act Transparency Statement|Sitemap|About US| Contact US: help@patsnap.com