High-stability aluminum alloy section and manufacturing process thereof

An aluminum alloy profile, high-stability technology, used in slender components, building components, etc., can solve the problems of low strength, low melting point, and low density of pure aluminum, and achieve the effects of beautiful appearance, damage prevention, and deformation prevention.

- Summary

- Abstract

- Description

- Claims

- Application Information

AI Technical Summary

Problems solved by technology

Method used

Image

Examples

specific Embodiment approach

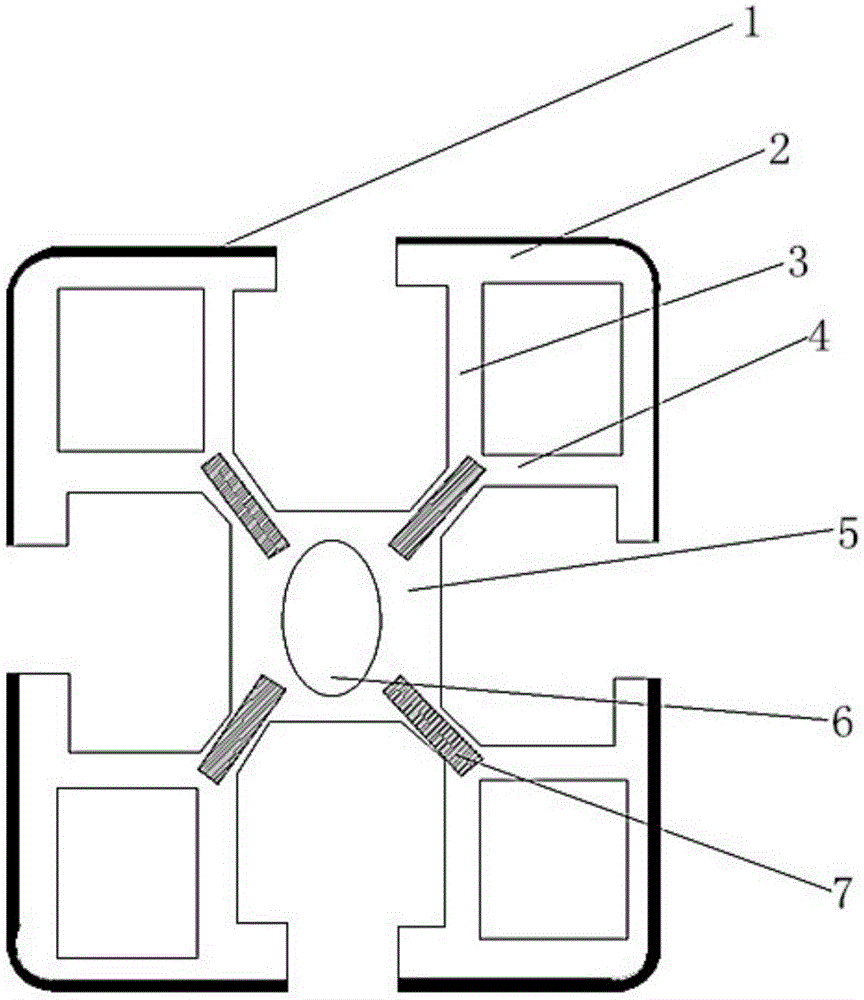

[0033] figure 1 and figure 2 A specific embodiment of a high-stability aluminum alloy profile of the present invention is shown: a high-stability aluminum alloy profile, consisting of a titanium coating 1, a load-bearing surface 2, a vertical beam 3, a transverse beam 4, a central frame 5, a central The hole 6 and the steel lining 7 are composed, the central frame 5 is square, the vertical beam 3 and the transverse beam 4 are arranged on each corner of the central frame 5 at right angles to each other, and the load-bearing surface 2 is arranged on the vertical beam 3 and the transverse beam 4 Above, it forms a square with the vertical beam 3 and the transverse beam 4, and the four load-bearing surfaces 2 corresponding to the central frame 5 form a square. At the joint, the titanium-coated layer 1 is arranged on the load-bearing surface 2 , and the central hole 6 is arranged at the center of the central frame 5 .

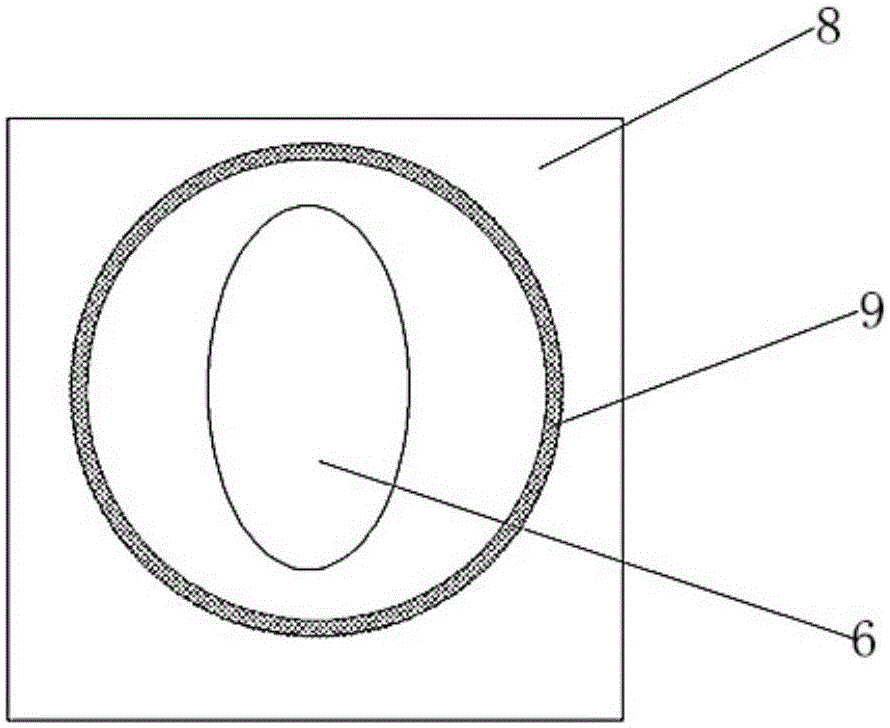

[0034] combine figure 2 The central frame 5 shown is compo...

PUM

Login to View More

Login to View More Abstract

Description

Claims

Application Information

Login to View More

Login to View More - R&D

- Intellectual Property

- Life Sciences

- Materials

- Tech Scout

- Unparalleled Data Quality

- Higher Quality Content

- 60% Fewer Hallucinations

Browse by: Latest US Patents, China's latest patents, Technical Efficacy Thesaurus, Application Domain, Technology Topic, Popular Technical Reports.

© 2025 PatSnap. All rights reserved.Legal|Privacy policy|Modern Slavery Act Transparency Statement|Sitemap|About US| Contact US: help@patsnap.com