Fly ash secondary combustion system and method for improving fly ash germanium grade

A secondary combustion and combustion system technology, applied in the field of pulverized coal combustion, can solve problems such as not giving a more detailed plan, and achieve the effects of overcoming the large carbon content of fly ash, increasing the slag collection rate, and improving efficiency

- Summary

- Abstract

- Description

- Claims

- Application Information

AI Technical Summary

Problems solved by technology

Method used

Image

Examples

Embodiment 1

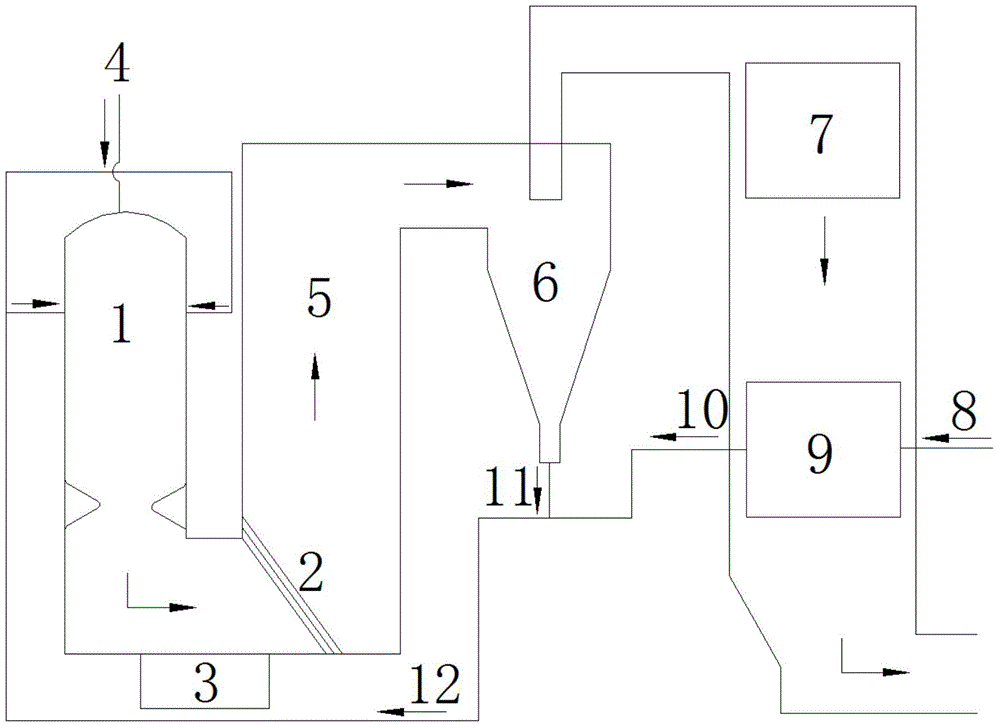

[0037] Such as figure 1 As shown, the fly ash secondary combustion system includes: the pre-chamber 1 of the vortex furnace, the slag catcher 2, the slag pool 3, the waste heat boiler 5, the high-temperature cyclone separator 6, the rear heating surface 7 and the air preheater 9, the vortex Furnace pre-chamber 1, slag catcher 2, waste heat boiler 5, high-temperature cyclone separator 6, rear heating surface 7 and air preheater 8 are sequentially connected, slag pool 3 is located at the bottom of vortex furnace pre-chamber 1; cold air Enter through the cold air inlet of the air preheater 8, and the hot air generated by heating is discharged through the hot air outlet, which is used to provide the air required for the combustion of germanium-containing lignite, and at the same time carry the fly ash 11 separated by the high-temperature cyclone separator 6 To the two hot air inlets located on both sides of the pre-chamber 1 of the vortex furnace, enter the pre-chamber 1 of the vo...

PUM

Login to View More

Login to View More Abstract

Description

Claims

Application Information

Login to View More

Login to View More - R&D

- Intellectual Property

- Life Sciences

- Materials

- Tech Scout

- Unparalleled Data Quality

- Higher Quality Content

- 60% Fewer Hallucinations

Browse by: Latest US Patents, China's latest patents, Technical Efficacy Thesaurus, Application Domain, Technology Topic, Popular Technical Reports.

© 2025 PatSnap. All rights reserved.Legal|Privacy policy|Modern Slavery Act Transparency Statement|Sitemap|About US| Contact US: help@patsnap.com