An acoustic fault detection device for a bearing system

A fault detection and bearing technology, applied in measuring devices, using electrical devices, measuring ultrasonic/sonic/infrasonic waves, etc., to achieve the effects of compact structure, expanded bandwidth and improved fault tolerance.

- Summary

- Abstract

- Description

- Claims

- Application Information

AI Technical Summary

Problems solved by technology

Method used

Image

Examples

Embodiment approach 1

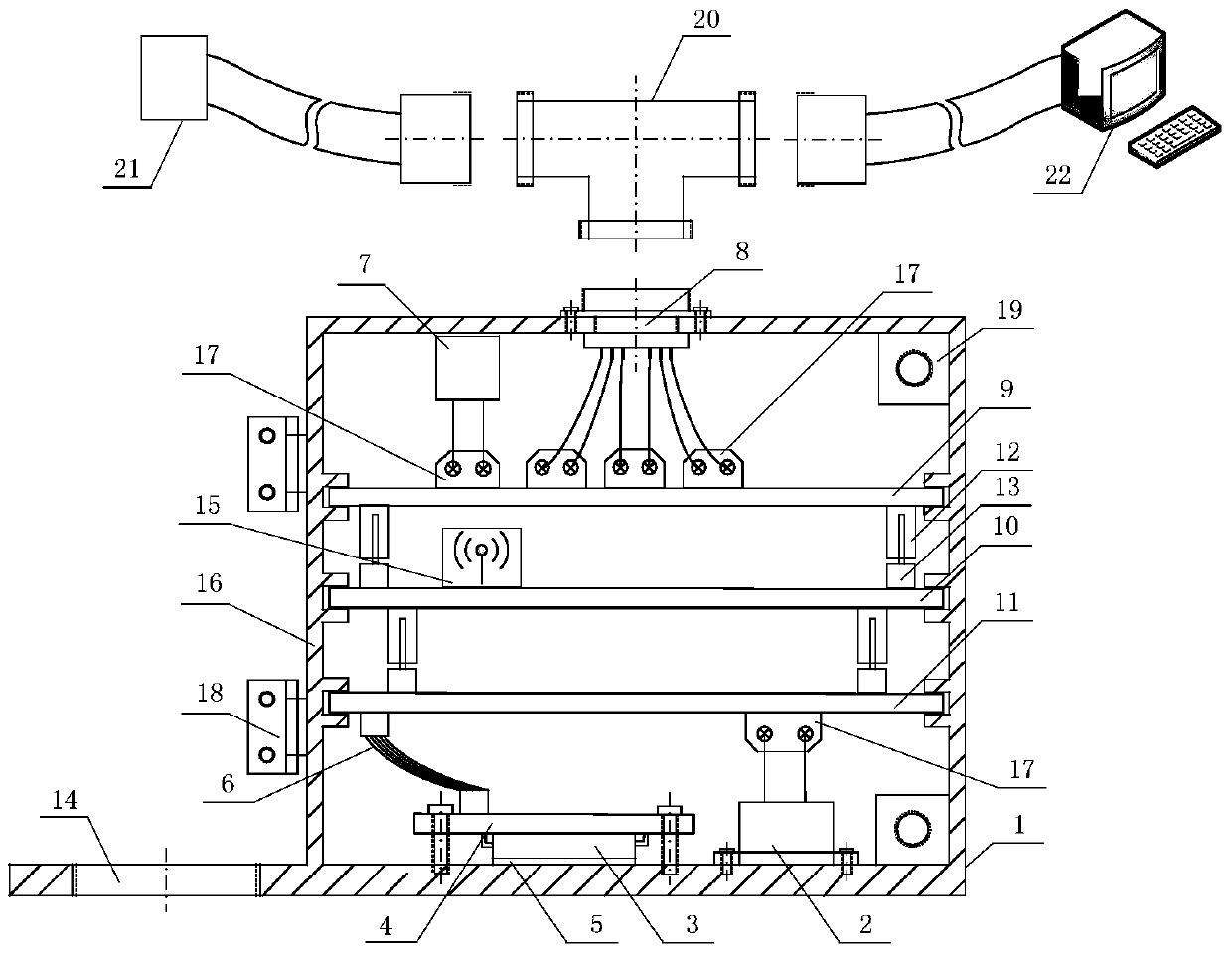

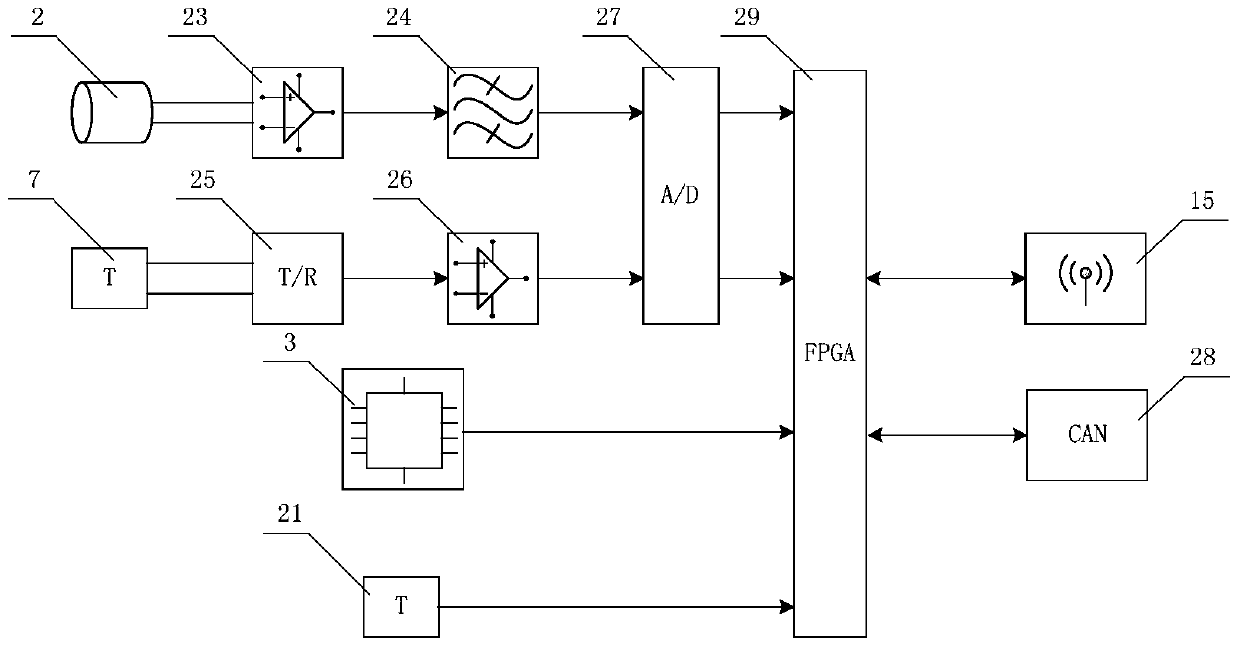

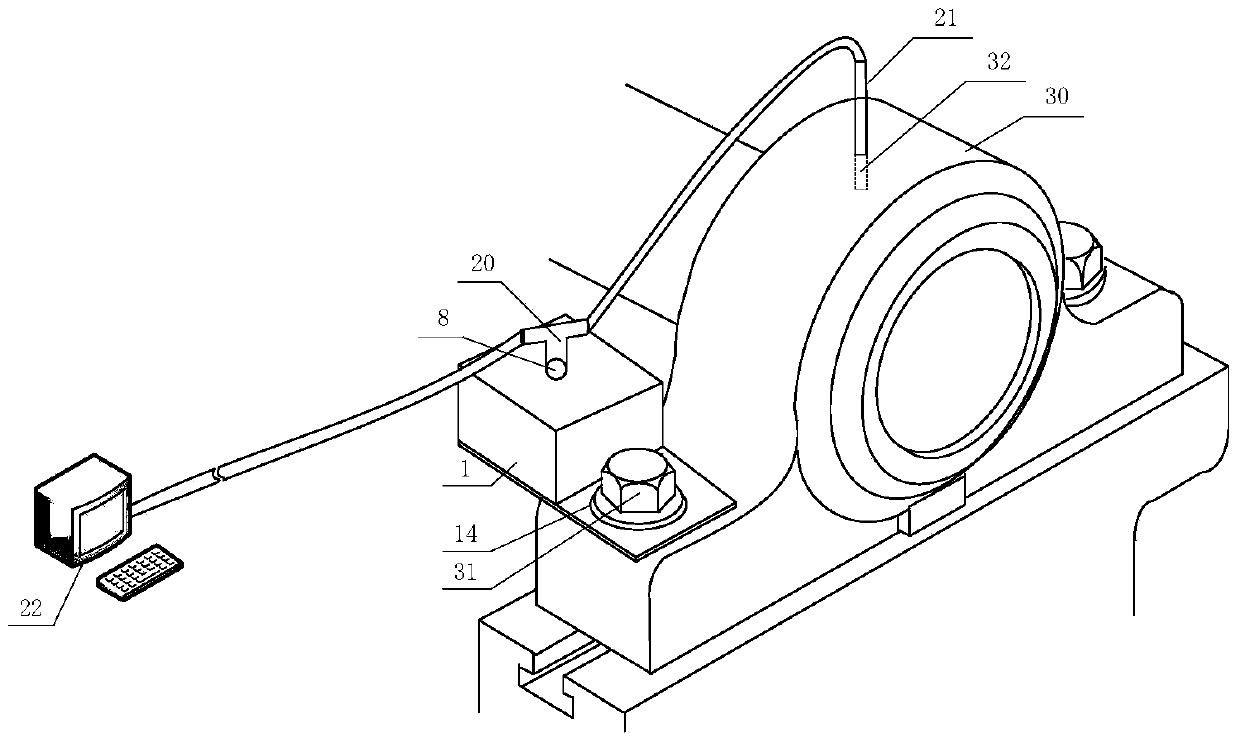

[0017] Attached below figure 1 , attached figure 2 And attached image 3 Further explain the application of a bearing system acoustic fault detection device of the present invention in bearing system acoustic vibration signal fault analysis, on-line detection and real-time alarm, as well as the working principle and installation method of the device of the present invention.

[0018] According to attached figure 1The electret capacitive acoustic sensor 2, the triaxial acceleration sensor 3, the first circuit board 4, the first temperature sensor 7, the second temperature sensor 21, the second circuit board 9, the third circuit board 10, and the fourth circuit board 11 Combined with the industrial-grade 3G transmission module 15 to form an integrated bearing system acoustic fault detection device, the second circuit board 9, the third circuit board 10 and the fourth circuit board 11 are respectively connected and fixed through the female header 12 and the pin header 13 to fo...

PUM

Login to View More

Login to View More Abstract

Description

Claims

Application Information

Login to View More

Login to View More - R&D

- Intellectual Property

- Life Sciences

- Materials

- Tech Scout

- Unparalleled Data Quality

- Higher Quality Content

- 60% Fewer Hallucinations

Browse by: Latest US Patents, China's latest patents, Technical Efficacy Thesaurus, Application Domain, Technology Topic, Popular Technical Reports.

© 2025 PatSnap. All rights reserved.Legal|Privacy policy|Modern Slavery Act Transparency Statement|Sitemap|About US| Contact US: help@patsnap.com