Method for improving precision of right angle cutting experiment of carbon fiber composite material

A technology of right-angle cutting and composite materials, which is applied in the field of cutting and processing of difficult-to-machine materials, can solve the problems of sample damage, aggravated tool wear, and damage under the surface, etc., and achieves the effect of simple device, easy operation, and improved experimental accuracy

- Summary

- Abstract

- Description

- Claims

- Application Information

AI Technical Summary

Problems solved by technology

Method used

Image

Examples

Embodiment Construction

[0018] The specific implementation of the present invention will be described in detail below in conjunction with the technical scheme and accompanying drawings.

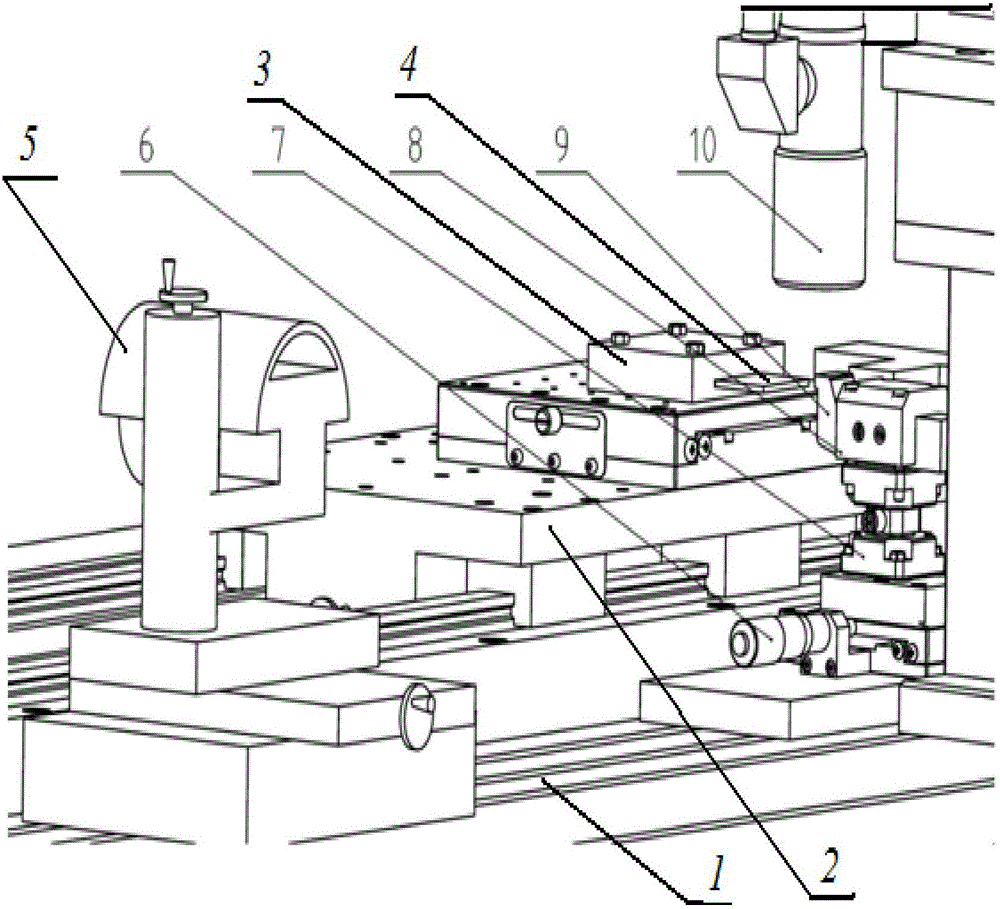

[0019] in the attached figure 1 Among them, a linear motor 2 , a micro-displacement platform 6 and an ultra-depth-of-field microscopic device 10 are installed on the bed 1 . The sample 4 is clamped by the sample holder 3 and installed on the mover of the linear motor 2 . During the experiment, the sample 4 carried by the mover of the linear motor 2 was pretreated by the three-axis grinder 5, the actual depth of cut was measured by the ultra-depth-of-field microscopic device 10, and the actual depth of cut was adjusted by adjusting the micro-displacement platform 6 to make it Same as the experimental preset depth of cut. Then restart the linear motor 2, set its speed as the right-angle cutting speed, and complete the right-angle cutting experiment. The speed adjustment range of the linear motor 2 is 0.1m / s~5m / s, a...

PUM

Login to View More

Login to View More Abstract

Description

Claims

Application Information

Login to View More

Login to View More - R&D

- Intellectual Property

- Life Sciences

- Materials

- Tech Scout

- Unparalleled Data Quality

- Higher Quality Content

- 60% Fewer Hallucinations

Browse by: Latest US Patents, China's latest patents, Technical Efficacy Thesaurus, Application Domain, Technology Topic, Popular Technical Reports.

© 2025 PatSnap. All rights reserved.Legal|Privacy policy|Modern Slavery Act Transparency Statement|Sitemap|About US| Contact US: help@patsnap.com