Pulsed infrared dust concentration detection circuit

A dust concentration detection, pulse-type technology, applied in the direction of measuring devices, suspension and porous material analysis, particle suspension analysis, etc., can solve the problems of large influence, low controllability, low precision, etc., to facilitate data collection and reduce Interference, the effect of improving the detection accuracy

- Summary

- Abstract

- Description

- Claims

- Application Information

AI Technical Summary

Problems solved by technology

Method used

Image

Examples

Embodiment Construction

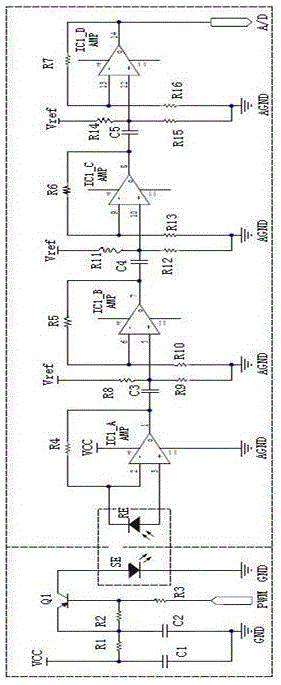

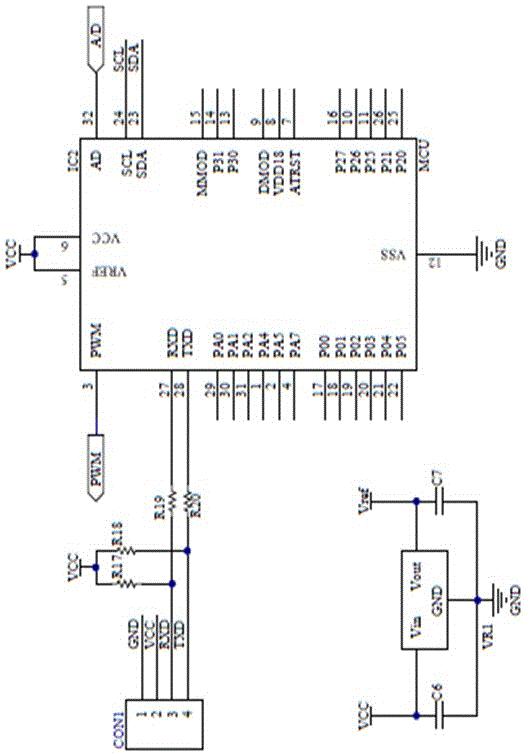

[0018] see figure 1 and figure 2 , the present invention is composed of two parts, an analog circuit part and a digital circuit part, wherein the digital circuit part provides a drive signal, and at the same time collects the final output signal of the analog circuit part.

[0019] The analog circuit part includes four stages of op amps connected in sequence, and the output terminal of the front stage op amp is connected with the non-inverting terminal of the latter stage op amp through a capacitor. Among them, the photoelectric tube is connected between the non-inverting terminal and the inverting terminal of the first-stage operational amplifier IC1_A, and the output terminal of the first-stage operational amplifier IC1_A is connected to the second-stage operational amplifier IC1_B, the third-stage operational amplifier IC1_C, and the fourth-stage operational amplifier. Put IC1_D. The output end of the fourth stage operational amplifier IC1_D is connected to the digital c...

PUM

Login to View More

Login to View More Abstract

Description

Claims

Application Information

Login to View More

Login to View More - R&D

- Intellectual Property

- Life Sciences

- Materials

- Tech Scout

- Unparalleled Data Quality

- Higher Quality Content

- 60% Fewer Hallucinations

Browse by: Latest US Patents, China's latest patents, Technical Efficacy Thesaurus, Application Domain, Technology Topic, Popular Technical Reports.

© 2025 PatSnap. All rights reserved.Legal|Privacy policy|Modern Slavery Act Transparency Statement|Sitemap|About US| Contact US: help@patsnap.com