Virtual assembly system based on Visual Basic and EON Studio

A technology of virtual assembly and automatic assembly, which is applied in the direction of program control devices, special data processing applications, instruments, etc., can solve problems such as inability to assemble, unreasonable assembly sequence, prolonging product production cycle, etc., to reduce the number of programming, production The effect of low cost and shortened R&D cycle

- Summary

- Abstract

- Description

- Claims

- Application Information

AI Technical Summary

Problems solved by technology

Method used

Image

Examples

Embodiment Construction

[0018] The present invention will be described in further detail below in conjunction with the accompanying drawings and embodiments.

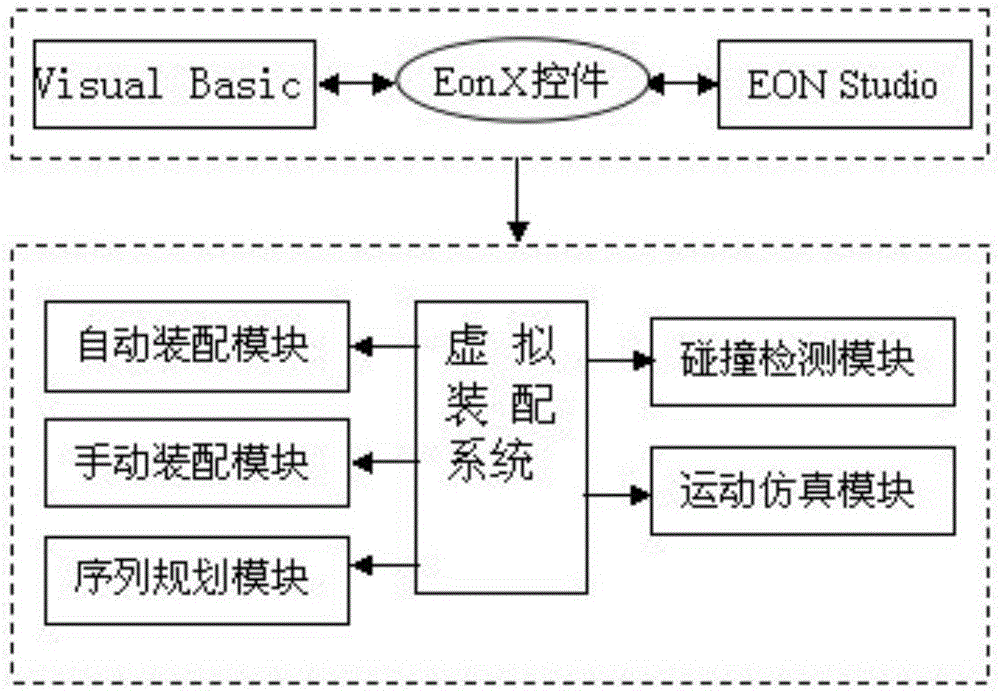

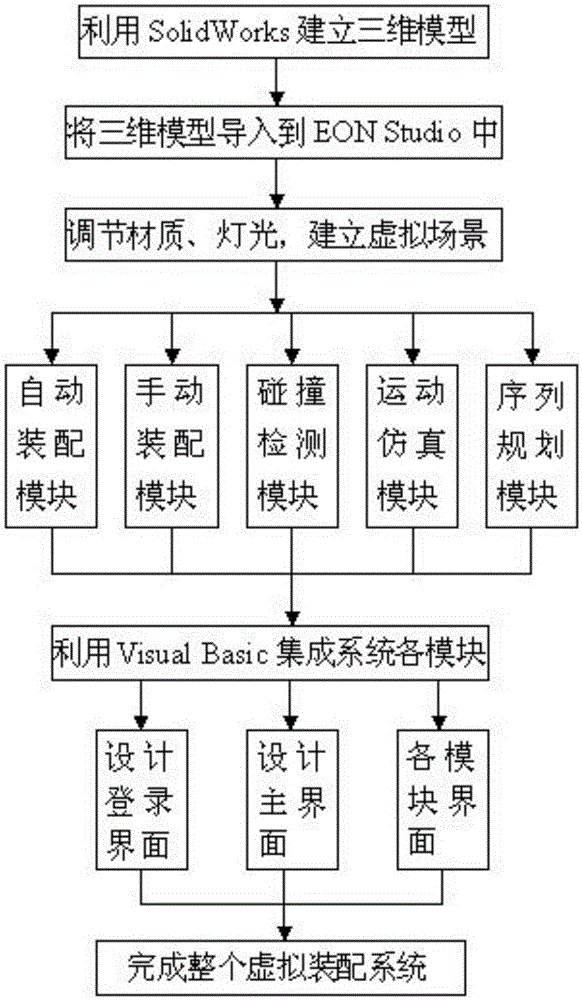

[0019] see figure 1 , a virtual assembly system based on VisualBasic and EONStudio, the system includes automatic assembly module, manual assembly module, motion simulation module, collision detection module, assembly sequence planning module, five functional modules are integrated in the VisualBasic integrated development tool, VisualBasic integrated The development tool is connected with the EONStudio simulation platform through the EonX control.

[0020]The automatic assembly module is realized based on the visual interface programming of VisualBasic, and the specific method is as follows: first, create a new VisualBasic application program, select "engineering-parts" in the main menu, and then in the pop-up "parts" window, select "EonX3.0TypeLibrary", you can add the EonX control to the application; then, drag the EonX control to the form...

PUM

Login to View More

Login to View More Abstract

Description

Claims

Application Information

Login to View More

Login to View More - R&D

- Intellectual Property

- Life Sciences

- Materials

- Tech Scout

- Unparalleled Data Quality

- Higher Quality Content

- 60% Fewer Hallucinations

Browse by: Latest US Patents, China's latest patents, Technical Efficacy Thesaurus, Application Domain, Technology Topic, Popular Technical Reports.

© 2025 PatSnap. All rights reserved.Legal|Privacy policy|Modern Slavery Act Transparency Statement|Sitemap|About US| Contact US: help@patsnap.com