Explosion-proof valve structure for pressure relief of lithium battery

A technology for explosion-proof valves and lithium batteries, which is applied to structural parts, battery pack components, circuits, etc., can solve the problems of relatively high precision in membrane manufacturing, difficult control of explosion-proof pressure, and battery failure, and achieve easy-to-control explosion-proof pressure and structural Simple, undamaged effect

- Summary

- Abstract

- Description

- Claims

- Application Information

AI Technical Summary

Problems solved by technology

Method used

Image

Examples

Embodiment Construction

[0012] The implementation of the present invention will be illustrated by specific specific examples below, and those skilled in the art can easily understand other advantages and effects of the present invention from the contents disclosed in this specification.

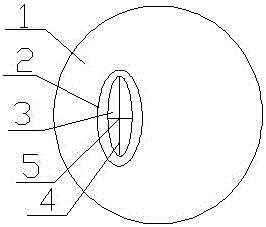

[0013] Such as figure 1 As shown, a lithium battery pressure relief explosion-proof valve structure includes a cover plate 1, a blast hole 2 is opened on one side of the cover plate 1, the structure of the blast hole 2 is oval, and a layer of thin wall is provided at the bottom of the blast hole 2 The bursting membrane 3, the thin-walled bursting membrane 3 and the cover plate 1 are integrally structured, which has a good sealing effect and prevents electrolyte leakage and outside air from entering; a blasting groove 4 is punched out on the bursting membrane 3, and the blasting groove 4 is a cross-shaped structure , the midpoint 5 of the cross blasting groove is a weak area, which is the concentration point of the i...

PUM

Login to View More

Login to View More Abstract

Description

Claims

Application Information

Login to View More

Login to View More - R&D

- Intellectual Property

- Life Sciences

- Materials

- Tech Scout

- Unparalleled Data Quality

- Higher Quality Content

- 60% Fewer Hallucinations

Browse by: Latest US Patents, China's latest patents, Technical Efficacy Thesaurus, Application Domain, Technology Topic, Popular Technical Reports.

© 2025 PatSnap. All rights reserved.Legal|Privacy policy|Modern Slavery Act Transparency Statement|Sitemap|About US| Contact US: help@patsnap.com