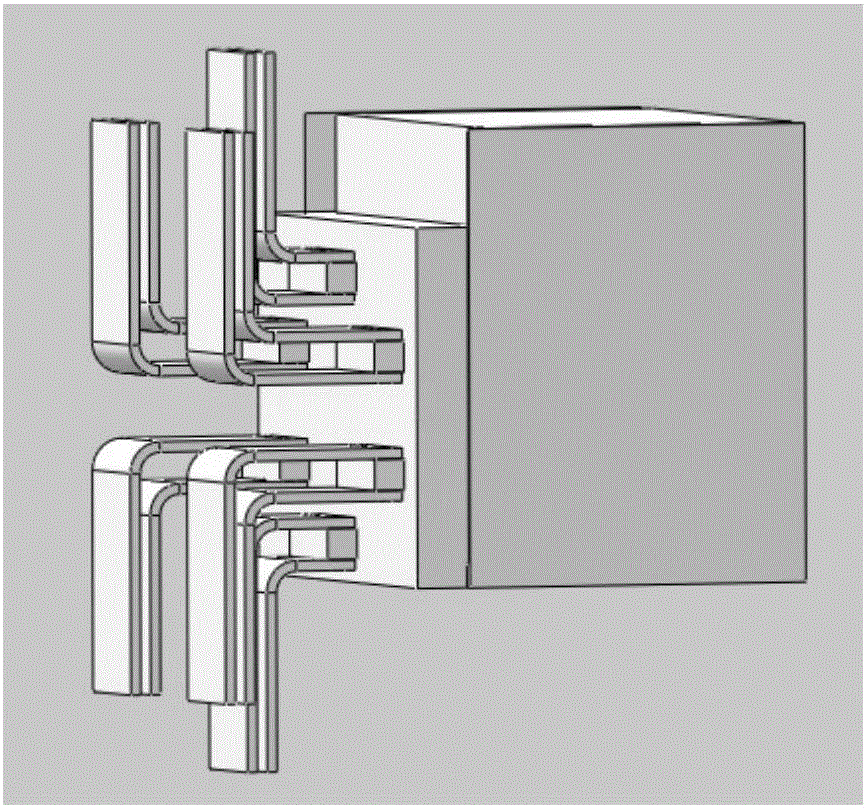

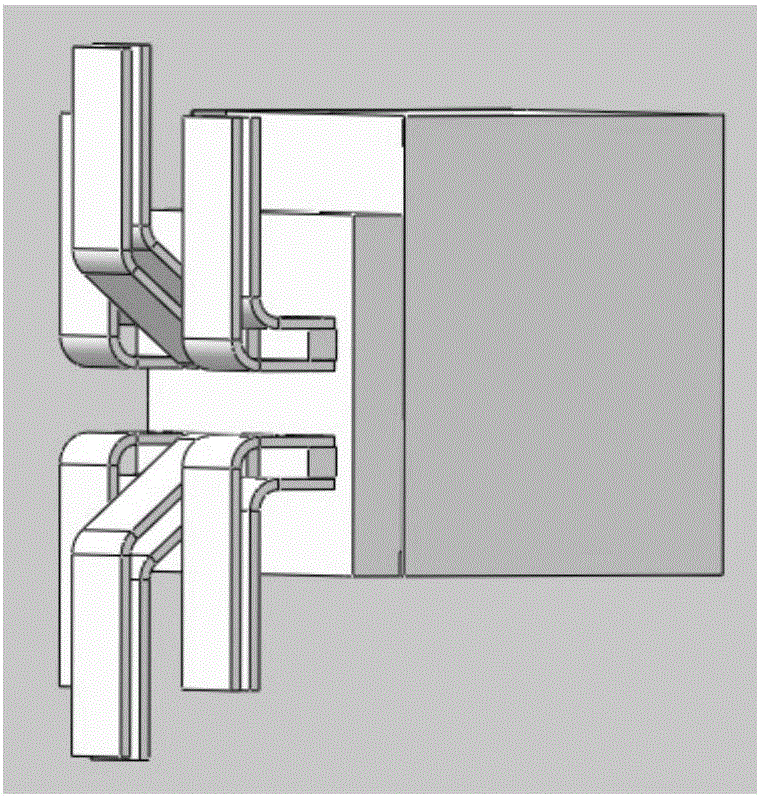

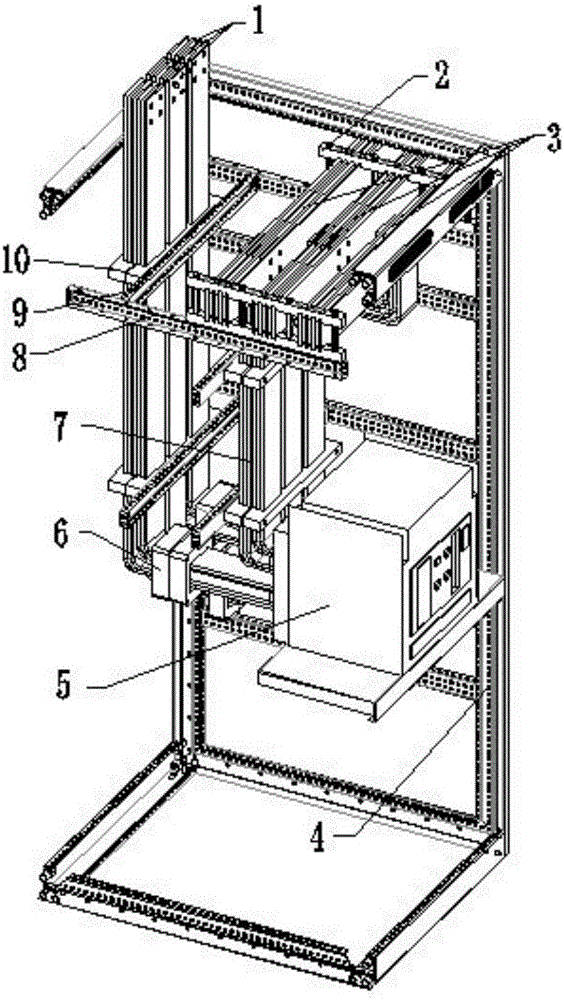

Three-phase buses in switch cabinet

A switchgear and busbar technology, applied in the field of structure and layout in low-voltage switchgear, can solve the problems of different mechanical properties, resistance to movement, poor thermal stability, and poor thermal stability of aluminum busbars, so as to increase the cross-sectional area and The effect of increasing the perimeter, increasing the modulus of the bending section, and enhancing the mechanical properties

- Summary

- Abstract

- Description

- Claims

- Application Information

AI Technical Summary

Problems solved by technology

Method used

Image

Examples

Embodiment Construction

[0051] In order to make the object, technical solution and advantages of the present invention clearer, the present invention will be further described in detail below in conjunction with the accompanying drawings and specific embodiments.

[0052] When selecting various high and low voltage equipment and conductors in the power system, it should be based on normal working conditions (including rated voltage, rated current, frequency, breaking current, etc.), short-circuit conditions (including thermal stability, dynamic stability, and short-circuit duration, etc.) , environmental conditions (including temperature, humidity, altitude medium state, etc.) and the characteristics of various equipment and conductors, comprehensively consider the selection. Among them, checking the thermal and dynamic stability of electrical equipment and conductors according to short-circuit conditions is a crucial task in the selection of electrical equipment and conductors. It is an important fac...

PUM

Login to View More

Login to View More Abstract

Description

Claims

Application Information

Login to View More

Login to View More - R&D

- Intellectual Property

- Life Sciences

- Materials

- Tech Scout

- Unparalleled Data Quality

- Higher Quality Content

- 60% Fewer Hallucinations

Browse by: Latest US Patents, China's latest patents, Technical Efficacy Thesaurus, Application Domain, Technology Topic, Popular Technical Reports.

© 2025 PatSnap. All rights reserved.Legal|Privacy policy|Modern Slavery Act Transparency Statement|Sitemap|About US| Contact US: help@patsnap.com