Electric heating two-stage polygonatum odoratum drying machine and application method thereof

An application method and secondary drying technology, applied in the direction of preserving fruits/vegetables through dehydration, etc., can solve the problems of resource waste and underutilization, etc.

- Summary

- Abstract

- Description

- Claims

- Application Information

AI Technical Summary

Problems solved by technology

Method used

Image

Examples

Embodiment 1

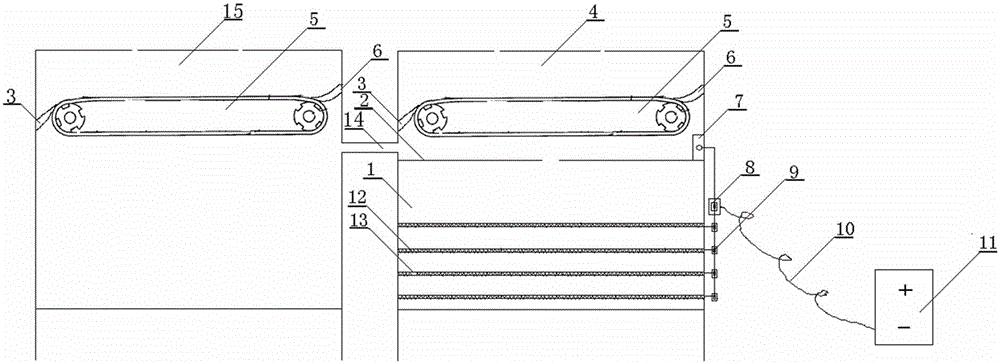

[0017] Example 1, such as figure 1 Shown is an electric heating two-stage Polygonatum odoratum dryer of the present invention, including a power supply 11, a control device connected to the power supply 11 through an electric wire 10, a heating device connected to the control device, and a heating device connected to the heating device. Drying unit connected to the unit.

[0018] The drying device includes a heat exchange chamber 1, a drying chamber 4 located above the heat exchange chamber 1, a secondary drying chamber 15 connected to the drying chamber 4 through a heat conduction channel 14, and a secondary drying chamber 15 located in the drying chamber. 4 and the conveyor belt 5 in the secondary drying chamber 15.

[0019] An air inlet is arranged at the bottom of the heat exchange chamber 1, and an inlet switch cover is arranged on the air inlet. A partition 2 is arranged between the heat exchange chamber 1 and the drying chamber 4, and rectangularly arranged pores are ...

Embodiment 2

[0025] Embodiment 2, embodiment 2 is different from embodiment 1 in that the area of the pores on the partition 2 accounts for 80% of the entire partition 2 area, and on the basis of embodiment 1, in the secondary drying chamber 15 An outer conveyor belt is arranged between the discharge port 3 and the feed port 6 of the drying chamber 4, and the outer conveyor belt transfers the materials coming out of the secondary drying chamber 15 to the drying chamber 4 for drying again. The transmission speed of the conveyor belt 5 in the secondary drying chamber 15 is the same as that of the conveyor belt 5 in the drying chamber 4 .

[0026] The application method of the present invention: when starting to work, turn on the power supply 1, the resistance wire 12 starts to heat, and at the same time, the inlet switch cover located at the lower part of the heat exchange chamber is opened. When the heating wire heats the surrounding air, the heated air rises and new cool air is added. T...

PUM

Login to View More

Login to View More Abstract

Description

Claims

Application Information

Login to View More

Login to View More - R&D

- Intellectual Property

- Life Sciences

- Materials

- Tech Scout

- Unparalleled Data Quality

- Higher Quality Content

- 60% Fewer Hallucinations

Browse by: Latest US Patents, China's latest patents, Technical Efficacy Thesaurus, Application Domain, Technology Topic, Popular Technical Reports.

© 2025 PatSnap. All rights reserved.Legal|Privacy policy|Modern Slavery Act Transparency Statement|Sitemap|About US| Contact US: help@patsnap.com