Crispy dried turnips and processing method thereof

A processing method and technology for crisp radish, applied in the application, food preparation, food science and other directions, can solve the problems of water, electricity and labor consumption, high production cost, long salting time, etc., to save equipment and labor costs, reduce processing costs , the effect of eliminating the desalination process

- Summary

- Abstract

- Description

- Claims

- Application Information

AI Technical Summary

Problems solved by technology

Method used

Image

Examples

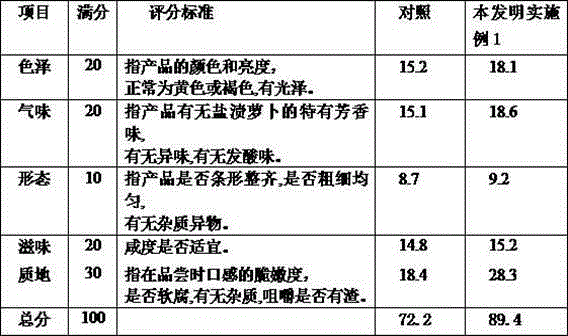

Embodiment 1

[0023] The processing method of 200 kilograms of crispy dried radish, its production steps are as follows:

[0024] (1) Making billets: take 600 kilograms of radishes by weighing, wash and drain, slice and cut into strips, and make strip blanks;

[0025] (2) Pickling for the first time: put the billet obtained in step (1) into a pickling container, add non-iodized salt (i.e. 18 kg of non-iodized salt) of 3% by weight of the billet, mix evenly, stir fully, and marinate for 10- After 12 hours, get rid of the salt solution, and make the first pickled radish strips;

[0026] (3) Pickle again: Add the initial pickled radish strips to 3% non-iodized salt (i.e. 18 kg non-iodized salt) of the weight of the strips, mix evenly, fully stir, and marinate for 6-8 hours;

[0027] (4) Squeeze dehydration: the semi-finished product obtained in step (3) is sent into an extruder for dehydration treatment, and the water content of the semi-finished product is controlled to 35-37%, to obtain deh...

Embodiment 2

[0036] The processing method of 400 kilograms of crispy dried radish, its production steps are as follows:

[0037] (1) making blank: take 1200 kilograms of radish by weighing, after washing and draining, slice and strip to make strip blank;

[0038] (2) Initial pickling: put the billet obtained in step (1) into a pickling container, add non-iodized salt (ie 42 kg of non-iodized salt) with a weight of 3.5% of the billet, mix well, stir fully, and marinate for 12 hours , get rid of the salt solution, and make the first pickled radish strips;

[0039](3) Pickling again: add the initial pickled radish strips to 3% non-iodized salt (i.e. 36 kg of non-iodized salt) of the weight of the strips, mix evenly, fully stir, and marinate for 8 hours;

[0040] (4) Squeeze dehydration: the semi-finished product obtained in step (3) is sent into an extruder for dehydration treatment, and the water content of the semi-finished product is controlled to 33-35%, to obtain dehydrated radish strip...

PUM

| Property | Measurement | Unit |

|---|---|---|

| Thickness | aaaaa | aaaaa |

Abstract

Description

Claims

Application Information

Login to View More

Login to View More - R&D

- Intellectual Property

- Life Sciences

- Materials

- Tech Scout

- Unparalleled Data Quality

- Higher Quality Content

- 60% Fewer Hallucinations

Browse by: Latest US Patents, China's latest patents, Technical Efficacy Thesaurus, Application Domain, Technology Topic, Popular Technical Reports.

© 2025 PatSnap. All rights reserved.Legal|Privacy policy|Modern Slavery Act Transparency Statement|Sitemap|About US| Contact US: help@patsnap.com