Preparation method of crisp plum wine having active ingredients of ginkgo folium and armillaria mellea

An active ingredient, a technology of crisp plum fruit wine, applied in the field of winemaking, can solve the problems of low brewing level and backward production technology of crisp plum fruit wine, etc.

- Summary

- Abstract

- Description

- Claims

- Application Information

AI Technical Summary

Problems solved by technology

Method used

Image

Examples

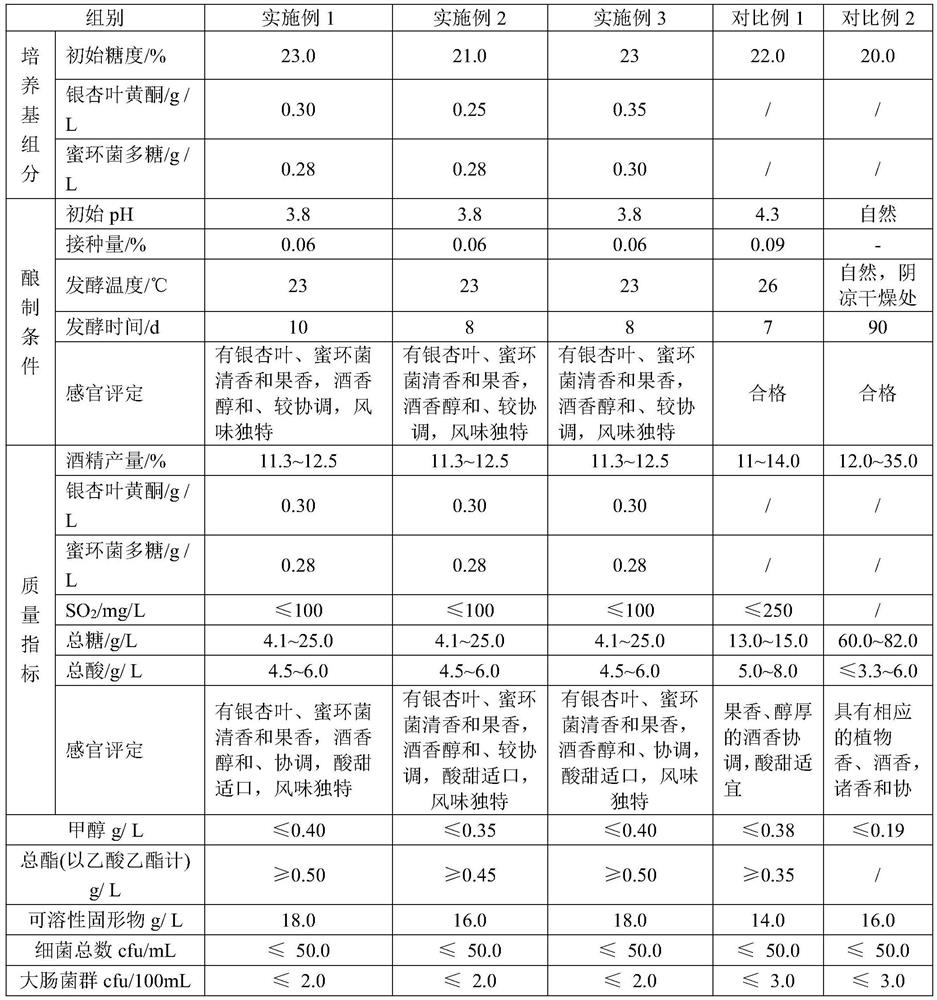

Embodiment 1

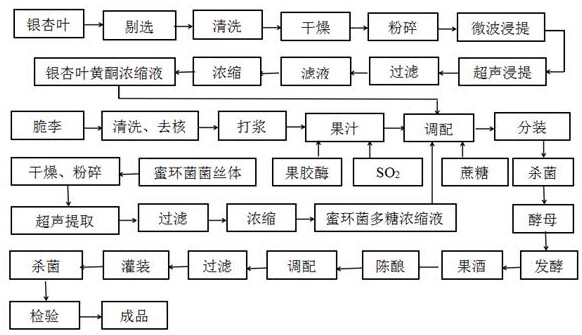

[0029] see figure 1 , a kind of preparation method of crispy plum wine with ginkgo leaf, armillaria active ingredient, comprises the steps:

[0030] S1. Dry ginkgo leaves at 40°C to 60°C until the water content of the leaves is about 10%, pulverize, pass through a 100-mesh sieve, add 60% ethanol to extract twice at a material-to-liquid ratio of 1:20, and combine the two extractions The supernatant was transferred to a rotary evaporator, evaporated and concentrated under reduced pressure at 60±1°C until the concentration of flavonoids was 5.5g / L, and the ginkgo leaf concentrate was obtained, which was stored at 4°C.

[0031]Filter the Armillaria mycelium, and vacuum-dry it at 60°C until the water content of the mycelium is about 10%, crush the mycelium, pass through a 100-mesh sieve, add distilled water at a material-to-liquid ratio of 1:25, and place it in an ultrasonic cell In a pulverizer, 370W ultrasonic extraction for 40min, filter, repeat the extraction once, combine the...

Embodiment 2

[0040] A preparation method of crispy plum wine with ginkgo leaves and armillaria active ingredients, comprising the steps of:

[0041] S1. Dry the ginkgo leaves at 40°C to 60°C until the water content of the leaves is 10%, crush them, pass through a 100-mesh sieve, add 60% ethanol to extract twice at a material-to-liquid ratio of 1:20, and combine the supernatants extracted twice liquid and transferred to a rotary evaporator, evaporated and concentrated under reduced pressure at 60±1°C until the concentration of flavonoids was 5.5g / L to obtain a concentrated solution of ginkgo biloba, which was stored at 4°C.

[0042] Filter the Armillaria mycelium, and vacuum-dry it at 60°C until the water content of the mycelium is 10%, crush the mycelium, pass through a 100-mesh sieve, add distilled water at a material-to-liquid ratio of 1:25, and then place ultrasonic cell crushing In the machine, 370W ultrasonic extraction for 40min, filter, repeat the extraction once, combine the filtra...

Embodiment 3

[0049] A preparation method of crispy plum wine with ginkgo leaves and armillaria active ingredients, comprising the steps of:

[0050] S1. Dry the ginkgo leaves at 40°C to 60°C until the water content of the leaves is 10%, crush them, pass through a 100-mesh sieve, add 60% ethanol to extract twice at a material-to-liquid ratio of 1:20, and combine the supernatants extracted twice liquid and transferred to a rotary evaporator, evaporated and concentrated under reduced pressure at 60±1°C until the concentration of flavonoids was 5.5g / L to obtain a concentrated solution of ginkgo biloba, which was stored at 4°C.

[0051] Filter the Armillaria mycelium, and vacuum-dry it at 60°C until the water content of the mycelium is 10%, crush the mycelium, pass through a 100-mesh sieve, add distilled water at a material-to-liquid ratio of 1:25, and then place ultrasonic cell crushing In the machine, 370W ultrasonic extraction for 40min, filter, repeat the extraction once, combine the filtra...

PUM

Login to View More

Login to View More Abstract

Description

Claims

Application Information

Login to View More

Login to View More - R&D

- Intellectual Property

- Life Sciences

- Materials

- Tech Scout

- Unparalleled Data Quality

- Higher Quality Content

- 60% Fewer Hallucinations

Browse by: Latest US Patents, China's latest patents, Technical Efficacy Thesaurus, Application Domain, Technology Topic, Popular Technical Reports.

© 2025 PatSnap. All rights reserved.Legal|Privacy policy|Modern Slavery Act Transparency Statement|Sitemap|About US| Contact US: help@patsnap.com