Welding method and welding device for thermocouple

A welding method and a welding device technology are applied in the field of thermocouple welding methods and welding devices, which can solve the problems of loss of experimental data production guidance, errors not obtained by scientific researchers, etc., so as to avoid losses, reduce temperature detection errors, and accurately detect temperature. Effect

- Summary

- Abstract

- Description

- Claims

- Application Information

AI Technical Summary

Problems solved by technology

Method used

Image

Examples

Embodiment

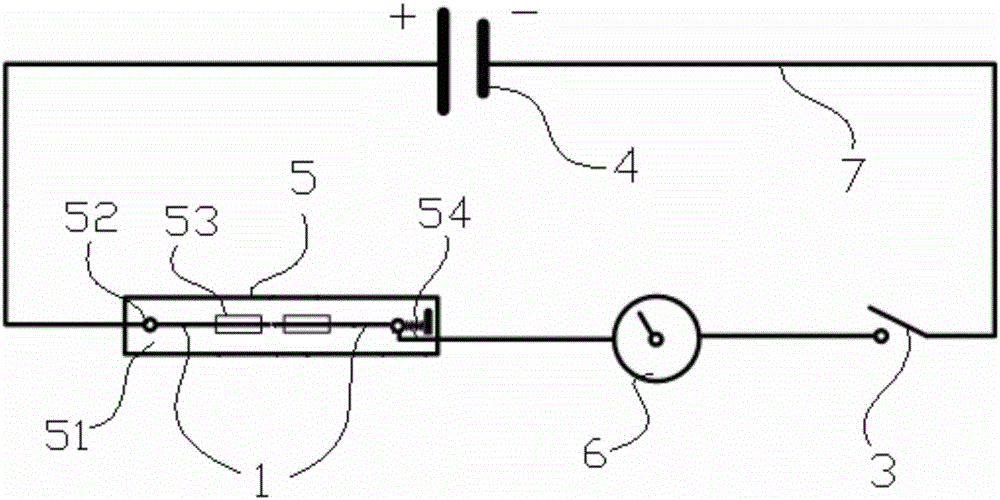

[0028] see image 3 , the thermocouple welding device in the illustration includes a DC power supply 4 , a welding station 5 and a time control unit 6 . Wherein, the welding station 5 includes an insulating base 51. The base 51 of this embodiment is made of a 10mm thick plexiglass plate. The positive and negative poles of the DC power supply 4 are connected by wires to form a DC welding circuit 7, and a time control unit 6 and a switch 3 are arranged in series on the circuit 7, wherein the time control unit 6 uses a time relay to control the welding circuit According to the thickness of the welding thermocouple wire, the on-time of the welding DC circuit is controlled between 0.01ms-1000ms. After the welding time is reached, the time relay automatically disconnects the circuit, and the switch 3 is the welding DC circuit. The main switch of the circuit.

[0029] There are two stoppers 53 between the two terminal posts 52, which are used to limit the welded thermocouple wires ...

PUM

Login to View More

Login to View More Abstract

Description

Claims

Application Information

Login to View More

Login to View More - R&D

- Intellectual Property

- Life Sciences

- Materials

- Tech Scout

- Unparalleled Data Quality

- Higher Quality Content

- 60% Fewer Hallucinations

Browse by: Latest US Patents, China's latest patents, Technical Efficacy Thesaurus, Application Domain, Technology Topic, Popular Technical Reports.

© 2025 PatSnap. All rights reserved.Legal|Privacy policy|Modern Slavery Act Transparency Statement|Sitemap|About US| Contact US: help@patsnap.com