Integrated transfer printing device integrating printing and transfer printing

A transfer printing and equipment technology, applied in transfer printing, printing, printing presses, etc., can solve the problems of difficult production cost, low surface tension, and decreased printing quality, and achieve the goal of reducing operating costs, circulating and updating smoothly, and compact equipment. Effect

- Summary

- Abstract

- Description

- Claims

- Application Information

AI Technical Summary

Problems solved by technology

Method used

Image

Examples

Embodiment 1

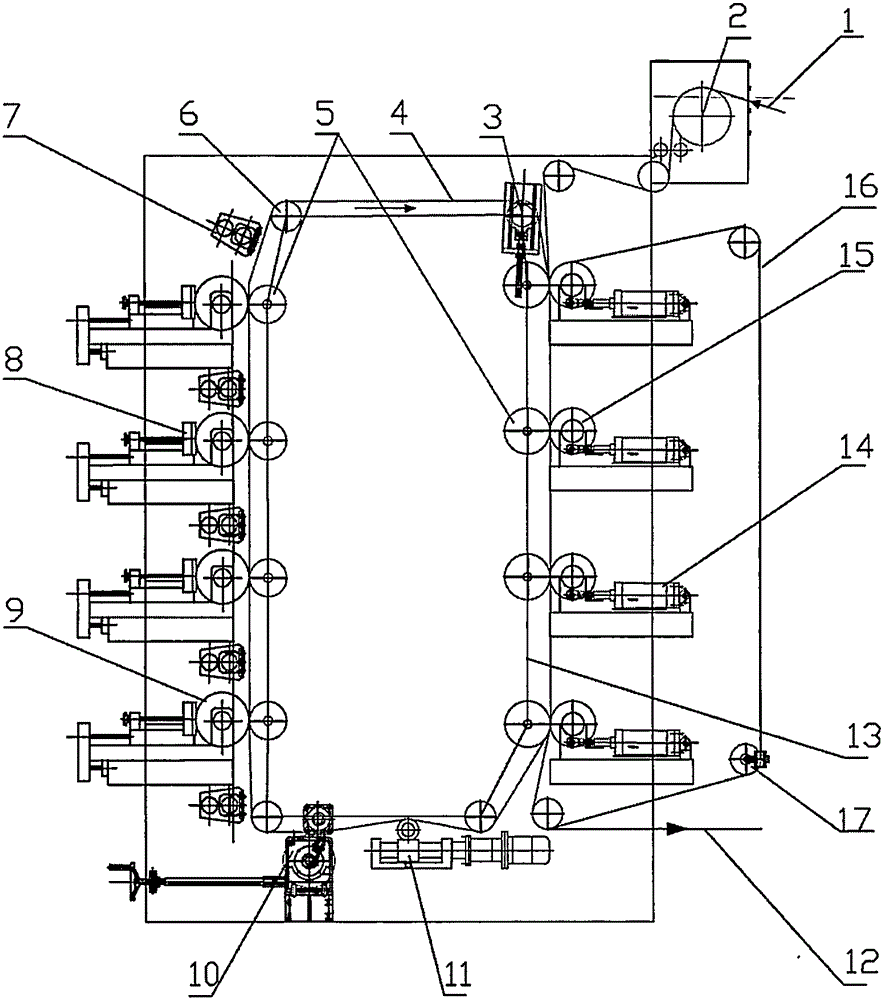

[0033] Embodiment 1 The transfer printing production of the transfer printing equipment composed of a stacked printing system and a stacked transfer printing system combined with an integrated transfer printing equipment.

[0034] The integrated printing transfer printing equipment uses the seamless ring-shaped transfer blanket belt 4 as the temporary transfer carrier, and the printing unit and the transfer unit are distributed on both sides of the frame 13 in a stacked manner, forming a stacked printing system and a stacked transfer printing system. System composed of printing and transfer united transfer printing equipment. Specifically, the equipment consists of a main frame 13, 2-8 printing units, 2-5 roll transfer units, a seamless endless transfer blanket belt 4, a blanket belt tensioning device 3, a blanket belt deviation correction device 11, a blanket belt Belt cleaning device 10, pressure roller 5, seamless endless blanket belt 16, blanket belt driving roller 17, inf...

Embodiment 2

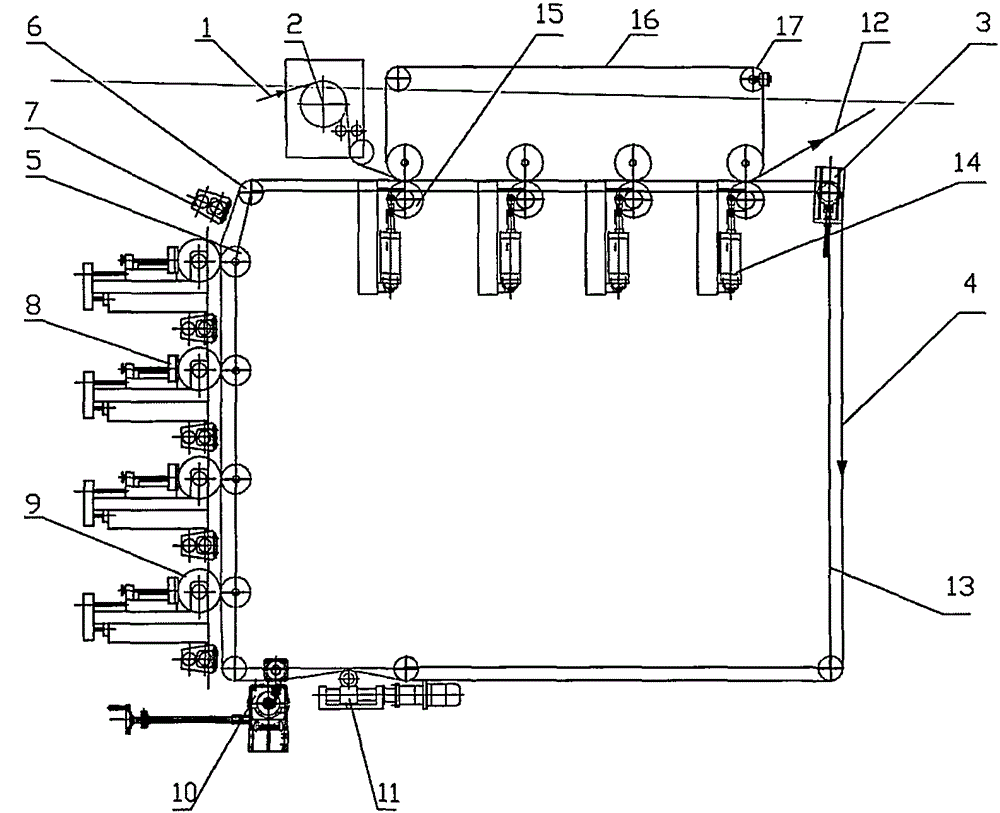

[0042] Example 2 The printing production of the combined transfer printing equipment consisting of a stacked printing system and a beam transfer printing system.

[0043] The integrated printing transfer printing equipment uses the seamless annular transfer blanket belt 4 as the temporary transfer carrier, and the stacked printing system and the beam transfer printing system are distributed on the frame 13 to form the integrated printing transfer printing equipment. Specifically, the equipment consists of a main frame 13, 2-8 printing units, 2-8 roll transfer units, a seamless endless transfer blanket belt 4, a blanket belt tensioning device 3, a blanket belt deviation correction device 11, a blanket belt Belt cleaning device 10, pressure roller 5, seamless endless blanket belt 16, blanket belt driving roller 17, infrared dryer 7, and fabric weft straightening device 2 and other mechanisms.

[0044] The laminated printing system is the same as that of Embodiment 1.

[0045] I...

Embodiment 3

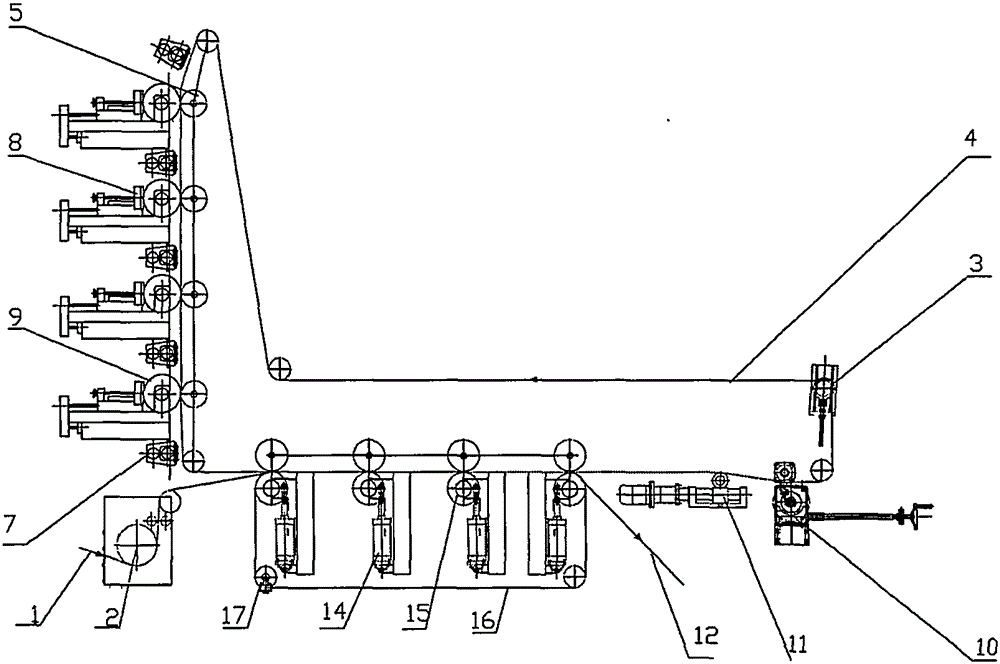

[0048] Example 3 The printing production of the combined transfer printing equipment consisting of a stacked printing system and a horizontal transfer printing system.

[0049] The integrated printing transfer printing equipment uses the seamless annular transfer blanket belt 4 as the temporary transfer carrier, and the stacked printing system and the horizontal transfer printing system are distributed on the frame 13 to form the integrated printing transfer printing equipment. Specifically, the equipment consists of a main frame 13, 2-8 printing units, 2-8 roll transfer units, a seamless endless transfer blanket belt 4, a blanket belt tensioning device 3, a blanket belt deviation correction device 11, a blanket belt Belt cleaning device 10, pressure roller 5, seamless endless blanket belt 16, blanket belt driving roller 17, infrared dryer 7, and fabric weft straightening device 2 and other mechanisms.

[0050] The laminated printing system is the same as that of Embodiment 1....

PUM

Login to View More

Login to View More Abstract

Description

Claims

Application Information

Login to View More

Login to View More - R&D

- Intellectual Property

- Life Sciences

- Materials

- Tech Scout

- Unparalleled Data Quality

- Higher Quality Content

- 60% Fewer Hallucinations

Browse by: Latest US Patents, China's latest patents, Technical Efficacy Thesaurus, Application Domain, Technology Topic, Popular Technical Reports.

© 2025 PatSnap. All rights reserved.Legal|Privacy policy|Modern Slavery Act Transparency Statement|Sitemap|About US| Contact US: help@patsnap.com