Production method of applying talcum powder into medicine powder

A technology of talcum powder and medicinal powder, which is applied in the directions of transportation and packaging, loading/unloading, packaging sterilization, etc. It can solve the problems of long production time, non-continuous production, and low sterilization ability, so as to increase production capacity and avoid secondary pollution Effect

- Summary

- Abstract

- Description

- Claims

- Application Information

AI Technical Summary

Problems solved by technology

Method used

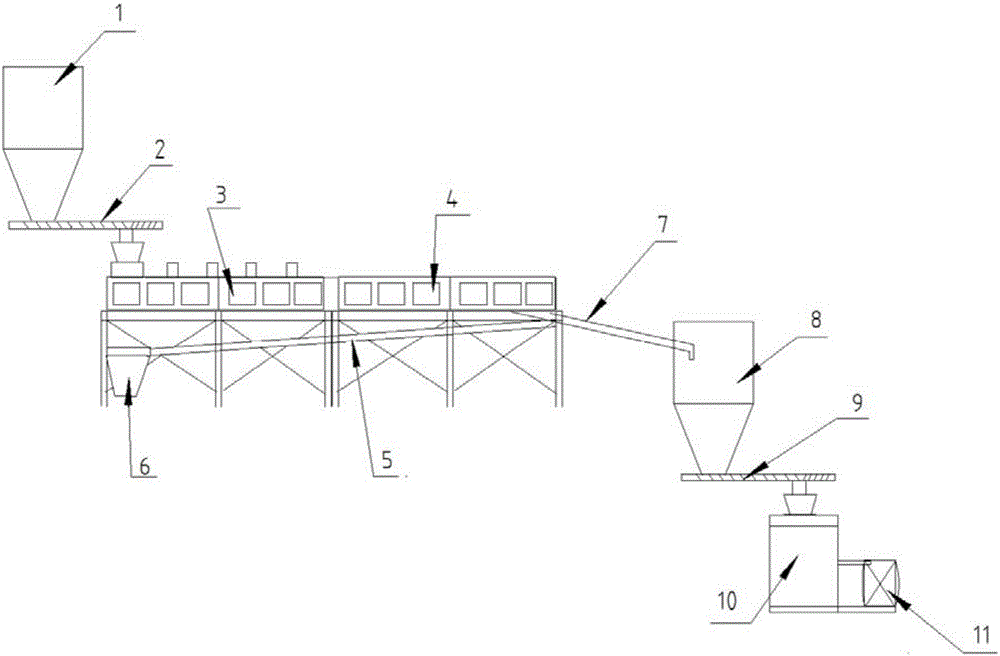

Image

Examples

Embodiment 1

[0035] The output of talcum powder is 2000Kg / 8 hours.

[0036] Talcum powder is applied to the production method of medicated powder, and concrete steps are as follows:

[0037] 1) Put the talc powder with a particle size of 325 mesh and a water content within 1% into the feeding bin;

[0038] 2) The closed automatic feeding machine sends the talc powder into the tunnel infrared drying and sterilization channel, the drying and sterilization temperature is 155°C, and the drying time is 45 minutes;

[0039] 3) The dried talcum powder enters the tunnel type ultraviolet sterilization channel, and the sterilization time is 50 minutes;

[0040] 4) The dried and sterilized talcum powder enters the discharge bin through a closed delivery pipeline and is allowed to stand for 12-24 hours to cool to room temperature;

[0041] 5) The cooled talcum powder enters the packaging machine through a screw feeder and is packed into small bags of 25Kg / bag.

Embodiment 2

[0043] The output of talcum powder is 2500Kg / 8 hours.

[0044] Talcum powder is applied to the production method of medicated powder, and concrete steps are as follows:

[0045] 1) Put the talc powder with a particle size of 325 mesh and a water content within 1% into the feeding bin;

[0046] 2) The closed automatic feeding machine sends the talc powder into the tunnel infrared drying and sterilization channel, the drying and sterilization temperature is 175°C, and the drying time is 35 minutes;

[0047] 3) The dried talcum powder enters the tunnel type ultraviolet sterilization channel, and the sterilization time is 40 minutes;

[0048] 4) The dried and sterilized talcum powder enters the discharge bin through a closed delivery pipeline and is allowed to stand for 12-24 hours to cool to room temperature;

[0049] 5) The cooled talcum powder enters the packaging machine through a screw feeder and is packed into small bags of 25Kg / bag.

PUM

| Property | Measurement | Unit |

|---|---|---|

| particle size (mesh) | aaaaa | aaaaa |

Abstract

Description

Claims

Application Information

Login to View More

Login to View More - R&D

- Intellectual Property

- Life Sciences

- Materials

- Tech Scout

- Unparalleled Data Quality

- Higher Quality Content

- 60% Fewer Hallucinations

Browse by: Latest US Patents, China's latest patents, Technical Efficacy Thesaurus, Application Domain, Technology Topic, Popular Technical Reports.

© 2025 PatSnap. All rights reserved.Legal|Privacy policy|Modern Slavery Act Transparency Statement|Sitemap|About US| Contact US: help@patsnap.com