Method and device for monitoring empty sleeve quality

A casing and measurement value technology, applied in the field of devices to realize the method, can solve the problems of damage and falling off of the line moving rod, and achieve the effect of reducing downtime and manpower use

- Summary

- Abstract

- Description

- Claims

- Application Information

AI Technical Summary

Problems solved by technology

Method used

Image

Examples

Embodiment Construction

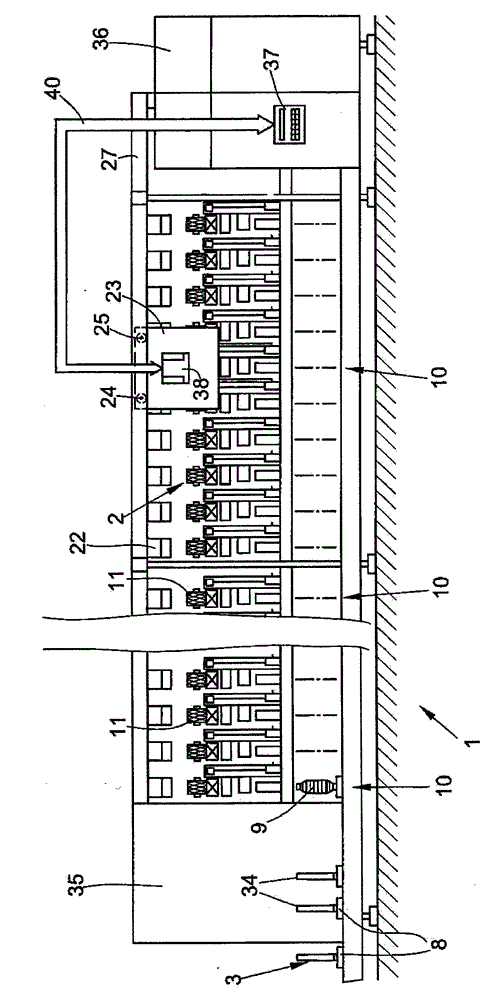

[0051] The invention is described below with reference to a winding machine 1 with a plurality of winding heads 2 . However, the invention can also be extended to other textile machines producing cross-wound bobbins.

[0052] figure 1 A winder, designated with reference number 1 , is shown schematically in front view. A winder 1 of this type generally has a plurality of similar workstations, preferably a winding head 2 located between its end frames 35 , 36 . On these winding heads 2 , as known and therefore not described in detail, bobbins 9 produced on a ring spinning machine (not shown) are rewound to form bulky cross-wound bobbins 11 .

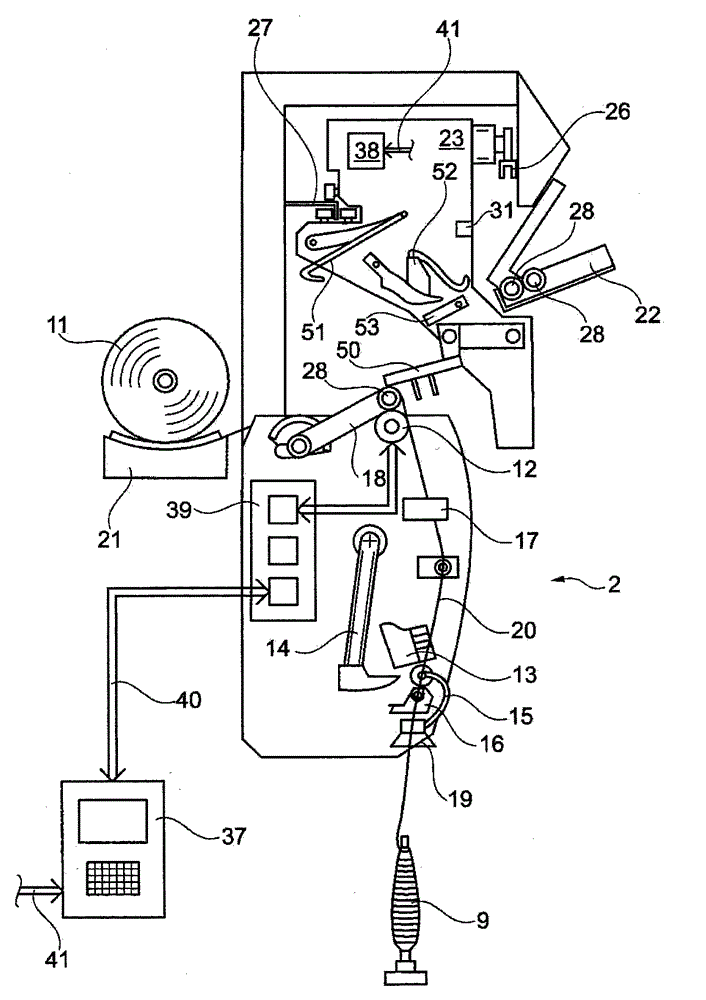

[0053] The entire cross-wound bobbin 11 is transferred to the cross-wound bobbin transfer mechanism 21, in particular to the textile machine, via an automatically working service assembly 23, subsequently called a cross-wound bobbin doffer, such as figure 2 shown, and then transferred to a bobbin loading station (not shown) or the lik...

PUM

Login to View More

Login to View More Abstract

Description

Claims

Application Information

Login to View More

Login to View More - R&D

- Intellectual Property

- Life Sciences

- Materials

- Tech Scout

- Unparalleled Data Quality

- Higher Quality Content

- 60% Fewer Hallucinations

Browse by: Latest US Patents, China's latest patents, Technical Efficacy Thesaurus, Application Domain, Technology Topic, Popular Technical Reports.

© 2025 PatSnap. All rights reserved.Legal|Privacy policy|Modern Slavery Act Transparency Statement|Sitemap|About US| Contact US: help@patsnap.com