Efficient water-processing method combining super-hydrophilicity nanofiltration membrane and super-hydrophobicity nanofiltration membrane

A nanofiltration membrane, super hydrophilic technology, applied in the field of membrane separation, can solve problems such as unimproved

- Summary

- Abstract

- Description

- Claims

- Application Information

AI Technical Summary

Problems solved by technology

Method used

Image

Examples

Embodiment 1

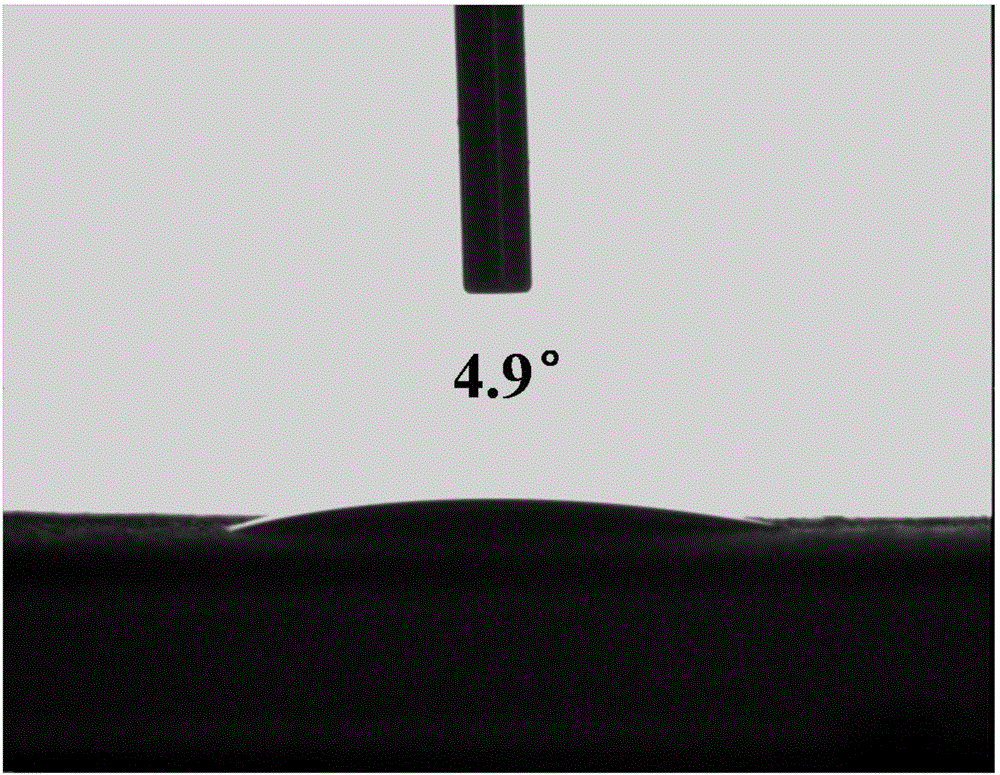

[0035] The water samples for the experiment were taken from the Jingmi Diversion Canal, with a relatively high content of hydrophobic substances, and the date of water collection was March 15, 2015. The super-hydrophilic membrane used is a flat nanofiltration membrane. When 5 μL of pure water is dropped on the surface of the membrane, the contact angle is 4.9° in 3 seconds, and the membrane area is 23 cm 2 . The super-hydrophobic membrane used is a flat-plate nanofiltration membrane. When 5 μL of pure water is dropped on the surface of the membrane, the contact angle is 162.2° in 3 seconds, and the membrane area is 23 cm 2 .

[0036] (1) Take 10L water sample, filter it with a 0.45 μm microporous membrane, and store it in a 4° refrigerator until use.

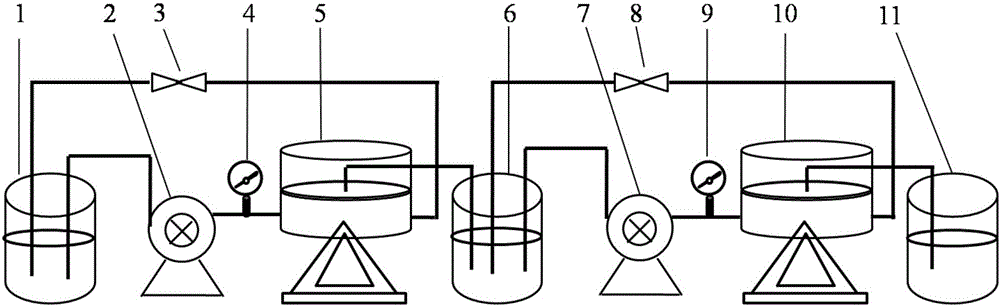

[0037] (2) Place the superhydrophilic membrane and the superhydrophobic membrane in 5 and 10 respectively.

[0038] (3) Take 5L of the solution in step (1) and put it into 1, turn on 2, adjust 3 so that the reading in 4 is st...

Embodiment 2

[0063] The water samples for the experiment were taken from the Jingmi Diversion Canal, with a relatively high content of hydrophobic substances, and the date of water collection was March 15, 2015. The super-hydrophilic membrane used is a flat nanofiltration membrane. When 5 μL of pure water is dropped on the surface of the membrane, the contact angle is 4.9° in 3 seconds, and the membrane area is 23 cm 2 . The super-hydrophobic membrane used is a flat-plate nanofiltration membrane. When 5 μL of pure water is dropped on the surface of the membrane, the contact angle is 162.2° in 3 seconds, and the membrane area is 23 cm 2 .

[0064] (1) Take 10L water sample, filter it with a 0.45μm microporous membrane, and store it in a 4° refrigerator until use.

[0065] (2) Place the superhydrophobic membrane and the superhydrophilic membrane in 5 and 10 respectively.

[0066] (3) Put 5L of the solution in step (1) into 1, turn on 2, adjust 3 so that the reading of 4 is stable at 0.6MP...

Embodiment 3

[0082] The water samples for the experiment were taken from the Jingmi Diversion Canal, with a relatively high content of hydrophobic substances, and the date of water collection was March 15, 2015. The super-hydrophilic membrane used is a flat nanofiltration membrane. When 5 μL of pure water is dropped on the surface of the membrane, the contact angle is 3.1° in 3 seconds, and the membrane area is 23 cm. 2 . The superhydrophobic membrane used is a flat-plate nanofiltration membrane. When 5 μL of pure water is dropped on the surface of the membrane, the contact angle is 167.2° in 3 seconds, and the membrane area is 23 cm 2 .

[0083] (1) Take 10L water sample, filter it with a 0.45μm microporous membrane, and store it in a 4° refrigerator until use.

[0084] (2) Place the superhydrophilic membrane and the superhydrophobic membrane in 5 and 10 respectively.

[0085] (3) Take 5L of the solution in step (1) and put it into 1, turn on 2, adjust 3 so that the reading in 4 is sta...

PUM

Login to View More

Login to View More Abstract

Description

Claims

Application Information

Login to View More

Login to View More - R&D

- Intellectual Property

- Life Sciences

- Materials

- Tech Scout

- Unparalleled Data Quality

- Higher Quality Content

- 60% Fewer Hallucinations

Browse by: Latest US Patents, China's latest patents, Technical Efficacy Thesaurus, Application Domain, Technology Topic, Popular Technical Reports.

© 2025 PatSnap. All rights reserved.Legal|Privacy policy|Modern Slavery Act Transparency Statement|Sitemap|About US| Contact US: help@patsnap.com