Compounding method and application of novel anti-freeze composite additive

A composite admixture and a new type of technology, applied in the field of building materials, can solve the problem of high early strength of concrete, and achieve the effect of promoting hardening, improving workability

- Summary

- Abstract

- Description

- Claims

- Application Information

AI Technical Summary

Problems solved by technology

Method used

Image

Examples

Embodiment Construction

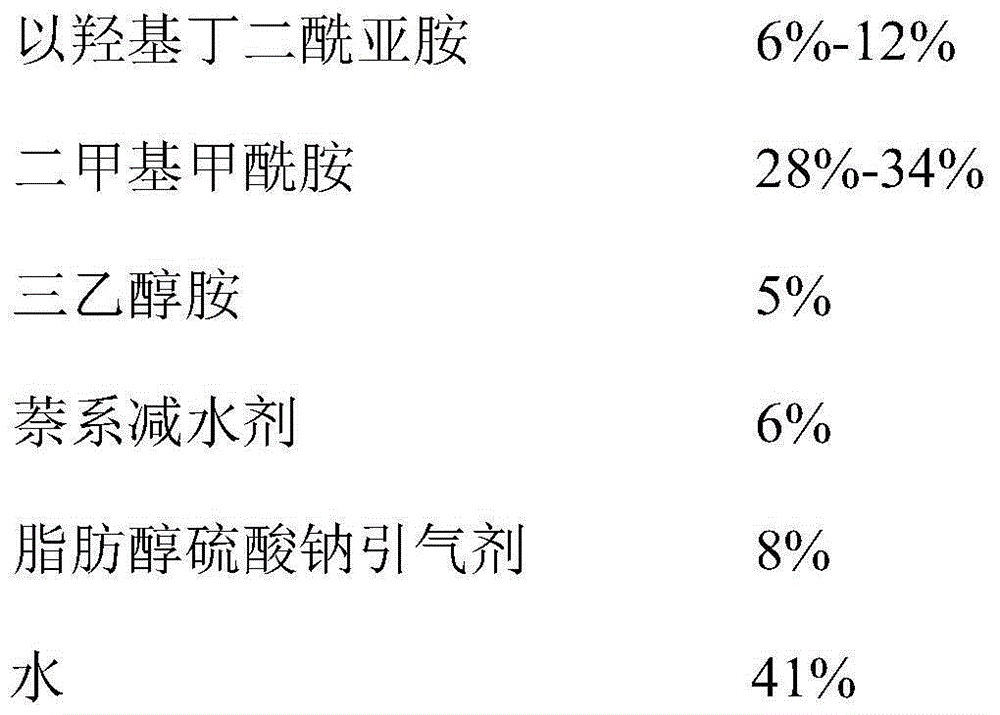

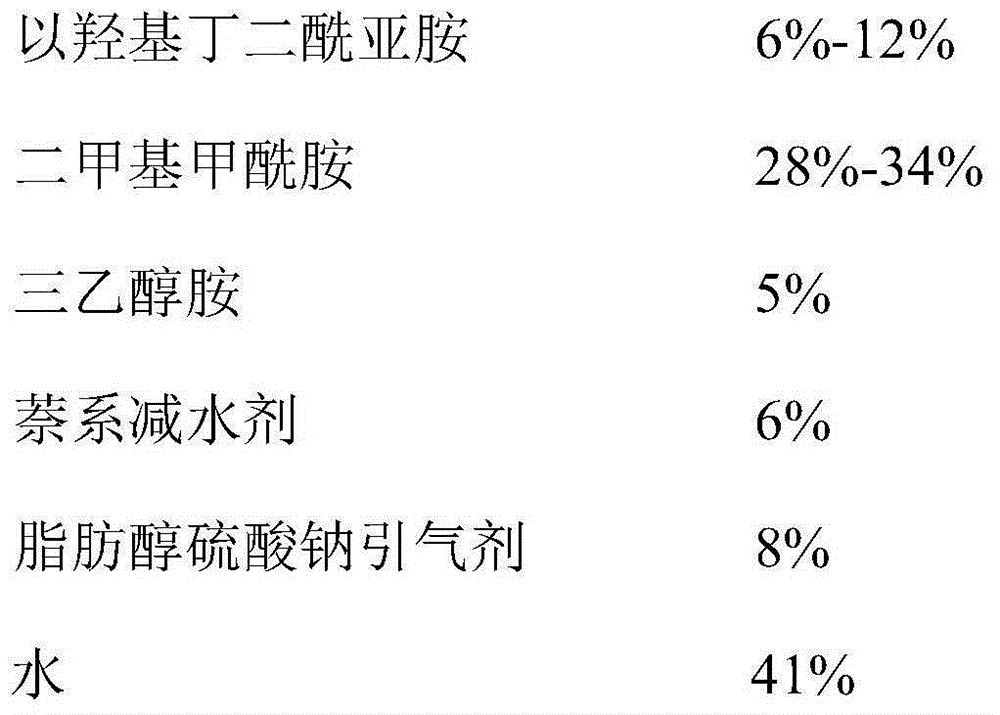

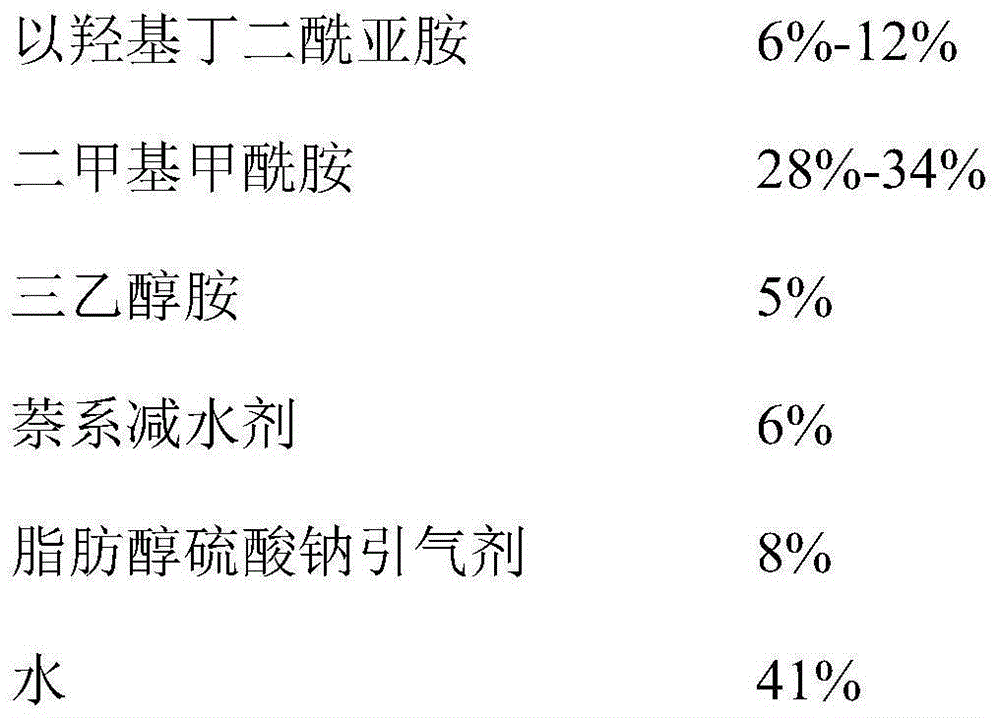

[0009] A novel antifreeze and antifreeze composite admixture, by weight percentage, comprises the following raw materials:

[0010]

[0011] The compounding method of a new type of antifreeze and antifreeze composite admixture includes sending dimethylformamide into a stirring container, adjusting the temperature to 45°C, starting stirring, adding hydroxysuccinimide, Triethanolamine, after mixing evenly, let it stand for heat preservation for 1 hour, send water into the chemical reaction kettle, heat it to 60°C, add naphthalene-based water reducer and fatty alcohol sodium sulfate air-entraining agent in turn while stirring until completely dissolved, then Stir and react for 1 hour, continue to stir after cooling down to normal temperature, add the mixture of hydroxysuccinimide, dimethylformamide and triethanolamine into the chemical reactor, stir and react for 1 hour, stop stirring and discharge, and obtain the finished product.

[0012] For the application of the new antif...

PUM

Login to View More

Login to View More Abstract

Description

Claims

Application Information

Login to View More

Login to View More - R&D

- Intellectual Property

- Life Sciences

- Materials

- Tech Scout

- Unparalleled Data Quality

- Higher Quality Content

- 60% Fewer Hallucinations

Browse by: Latest US Patents, China's latest patents, Technical Efficacy Thesaurus, Application Domain, Technology Topic, Popular Technical Reports.

© 2025 PatSnap. All rights reserved.Legal|Privacy policy|Modern Slavery Act Transparency Statement|Sitemap|About US| Contact US: help@patsnap.com