Water blocking type kerb and construction method thereof

A construction method and curb technology, applied in the direction of gutters/curbs, climate change adaptation, etc., can solve the problems of stormwater road damage, stormwater traffic accidents, high reconstruction costs, etc., to achieve improved efficiency, fast installation speed, and economical High benefit effect

- Summary

- Abstract

- Description

- Claims

- Application Information

AI Technical Summary

Problems solved by technology

Method used

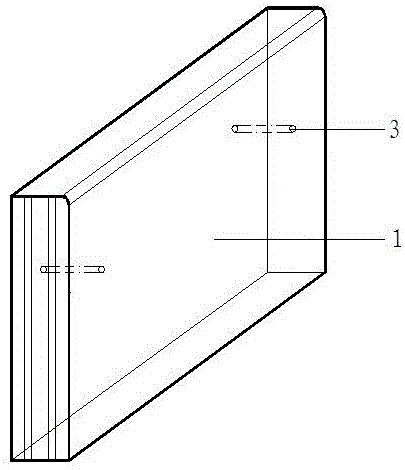

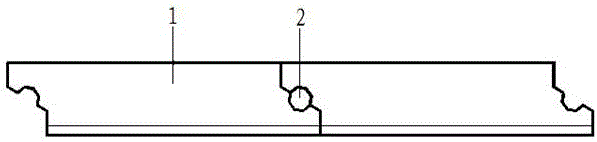

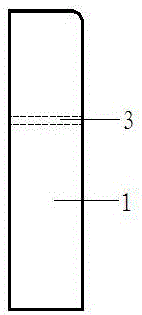

Image

Examples

Embodiment 1

[0038] Example 1: Construction process

[0039] (1) The construction process of water-blocking curbs on slope green space is as follows:

[0040] Survey → foundation construction → water blocking curb installation → filter layer construction → back concrete construction and backfill → sidewalk (or roadway) construction → water blocking hole blocking → graded gravel side ditch → sidewalk (or non- Motorway) construction.

[0041] (2) The construction process of high flowerbed water blocking curbs on both sides of the road is as follows:

[0042] Survey → foundation construction → water blocking curb installation → filter layer construction → back concrete construction and backfill → sidewalk (or roadway) construction → water blocking curb water blocking hole blocking → overflow well construction → sidewalk Or non-motor vehicle lane construction.

[0043] (3) The construction process of high flowerbed water-blocking curbs in the building community is as follows:

[0044] Survey → foundati...

Embodiment 2

[0045] Example 2: Specific process flow

[0046] (1) Measuring and setting out

[0047] The surveyor calculates the coordinates and elevation of the curb stone according to the construction drawings, and installs the control piles of the curb stone. The pile distance in the straight section should be 10-15m; the pile distance in the curved section should be 5-10m; the pile distance at the intersection should be 1-5m . The topography and topography should be combined when laying curbs.

[0048] (2) Curb foundation construction

[0049] The curb foundation should be rammed with 12% lime soil or C 15 Concrete foundation; lime soil thickness should not be less than 15cm, C 15 The thickness of the concrete foundation should not be less than 10cm; if the foundation is collapsible, the thickness of lime soil should not be less than 30cm.

[0050] (3) Water blocking curb installation

[0051] Installation sequence: install in sections according to intersections and flower beds, from the middle...

Embodiment 3

[0071] Example 3: Sidewalk (non-motor vehicle lane) construction

[0072] (1) In order to avoid water seepage on the sidewalk (non-motorized vehicle road), the construction shall be carried out after the water blocking curb is completed.

[0073] (2) The raw materials of permeable pavement can only be used after passing the test.

[0074] (3) Permeable pavement engineering must first construct the test section, and summarize the mix ratio and construction parameters. After meeting the design and specification requirements, construct the final mix ratio and construction parameters.

[0075] (4) The construction of permeable cement concrete pavement shall comply with CJJ1 and CJJ / T135 of "Code for Construction and Quality Acceptance of Urban Roads" and CJJ / T135 of "Technical Regulations for Permeable Cement Concrete Pavements", as well as the following requirements: Water permeability coefficient should be 0.5-1. ; The continuous porosity should not be less than 15%.

PUM

Login to View More

Login to View More Abstract

Description

Claims

Application Information

Login to View More

Login to View More - R&D

- Intellectual Property

- Life Sciences

- Materials

- Tech Scout

- Unparalleled Data Quality

- Higher Quality Content

- 60% Fewer Hallucinations

Browse by: Latest US Patents, China's latest patents, Technical Efficacy Thesaurus, Application Domain, Technology Topic, Popular Technical Reports.

© 2025 PatSnap. All rights reserved.Legal|Privacy policy|Modern Slavery Act Transparency Statement|Sitemap|About US| Contact US: help@patsnap.com