A semi-hydraulic coupler

A technology of hydraulic coupler and shell, applied in the direction of fluid transmission, belt/chain/gear, mechanical equipment, etc., can solve the problems of large working cavity diameter, low mechanical efficiency, narrow speed regulation range, etc., to achieve small size, The effect of light weight and wide speed range

- Summary

- Abstract

- Description

- Claims

- Application Information

AI Technical Summary

Problems solved by technology

Method used

Image

Examples

Embodiment Construction

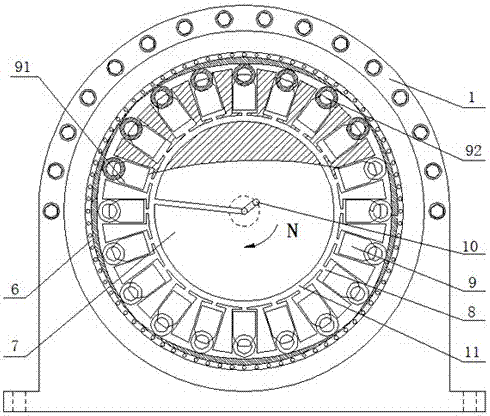

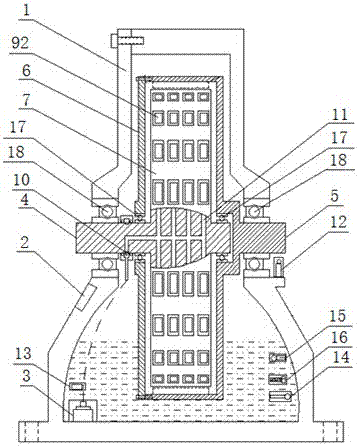

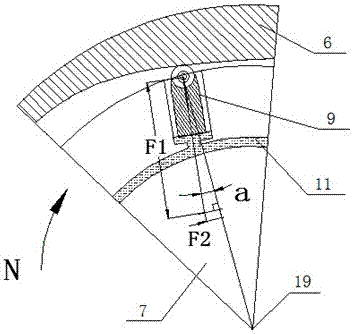

[0028] See figure 1 As shown in Fig. 2, a semi-hydraulic coupling includes a housing 1, a control unit 2 arranged on the outer wall of the housing 1, a high-pressure oil pump 3 arranged in the housing 1 and located at the bottom, and the outer ends of which extend into the outside of the housing 1 The input shaft 4 and output shaft 5, the outer rotor 6 installed in the casing 1 and fixedly connected with the output shaft 5, and the inner rotor 7 sleeved inside the outer rotor 6 and fixedly connected with the input shaft 4; the inner wall of the outer rotor 6 It is a circular variable-diameter curved surface, and the variable-diameter curved surface is evenly divided into multiple equal-divided curved surfaces, each equal-divided curved surface has the same variable-diameter size and direction, and the outer wall of the inner rotor 7 is provided with multiple laps of movable tooth slots 8 , the movable teeth 9 are embedded into the corresponding movable tooth grooves 8 one by ...

PUM

Login to View More

Login to View More Abstract

Description

Claims

Application Information

Login to View More

Login to View More - R&D

- Intellectual Property

- Life Sciences

- Materials

- Tech Scout

- Unparalleled Data Quality

- Higher Quality Content

- 60% Fewer Hallucinations

Browse by: Latest US Patents, China's latest patents, Technical Efficacy Thesaurus, Application Domain, Technology Topic, Popular Technical Reports.

© 2025 PatSnap. All rights reserved.Legal|Privacy policy|Modern Slavery Act Transparency Statement|Sitemap|About US| Contact US: help@patsnap.com