Differential shell and forging process and forging equipment thereof

A differential gear and equipment technology, applied in the field of driven spiral bevel gear combined forgings, can solve the problems of limited number of workpieces, low efficiency, high labor intensity, etc., and achieve the effects of improving heat treatment efficiency, meeting matching requirements, and saving weight

- Summary

- Abstract

- Description

- Claims

- Application Information

AI Technical Summary

Problems solved by technology

Method used

Image

Examples

Embodiment Construction

[0038] The present invention is described in detail below in conjunction with accompanying drawing and specific embodiment:

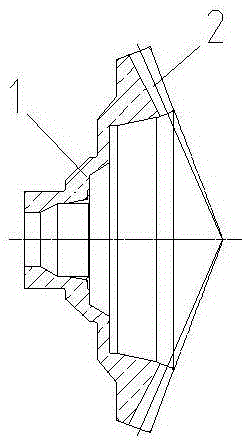

[0039] figure 1 As shown, a driven bevel gear combined forging includes a driven spiral bevel gear 2 and a differential case 1 on one side of the gear.

[0040] The combined passive bevel gear forging of this embodiment is forged through a die, so the ring gear 2 (gear) and the housing body 1 of this embodiment are an integrated forged structure instead of the original bolt-fastened structure.

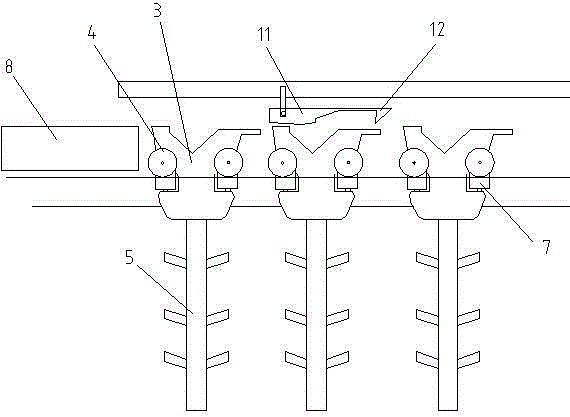

[0041]A pre-forging heat treatment process for driven spiral bevel gear combined forgings. Before the forging of the workpiece, the blank is heated at medium frequency for 2 minutes to 1100±50°C, and then 2 tons of air hammer is used for upsetting, and 4000 tons of screw pressure is used. machine for closed die forging, and then use a 300-ton punching machine to punch holes.

[0042] The commonly used pre-heat treatment process for forging blanks of automotive...

PUM

Login to View More

Login to View More Abstract

Description

Claims

Application Information

Login to View More

Login to View More - R&D

- Intellectual Property

- Life Sciences

- Materials

- Tech Scout

- Unparalleled Data Quality

- Higher Quality Content

- 60% Fewer Hallucinations

Browse by: Latest US Patents, China's latest patents, Technical Efficacy Thesaurus, Application Domain, Technology Topic, Popular Technical Reports.

© 2025 PatSnap. All rights reserved.Legal|Privacy policy|Modern Slavery Act Transparency Statement|Sitemap|About US| Contact US: help@patsnap.com