A kind of preparation method of cu-al-mn shape memory alloy gradient functional material

A technology of gradient functional materials and memory alloys, which is applied in the field of metal material preparation, can solve the problems of inability to prepare and have stability, and achieve the effects of small influence of martensitic transformation temperature, high controllability and simple process operation.

- Summary

- Abstract

- Description

- Claims

- Application Information

AI Technical Summary

Problems solved by technology

Method used

Image

Examples

Embodiment 1

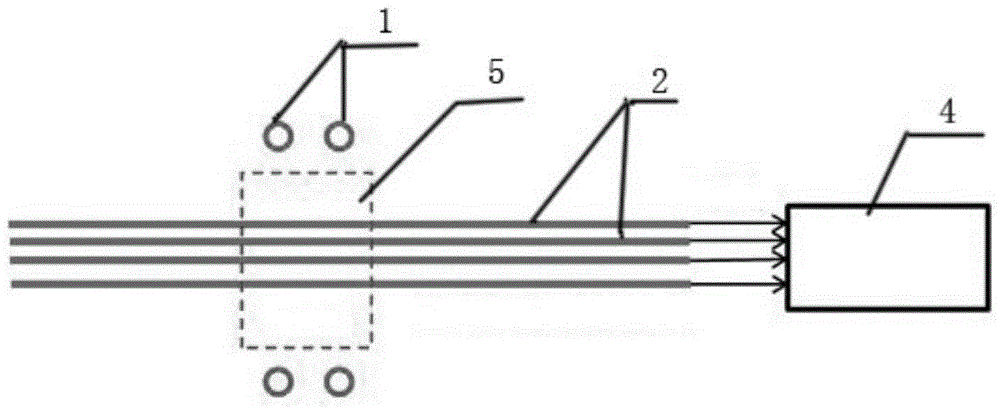

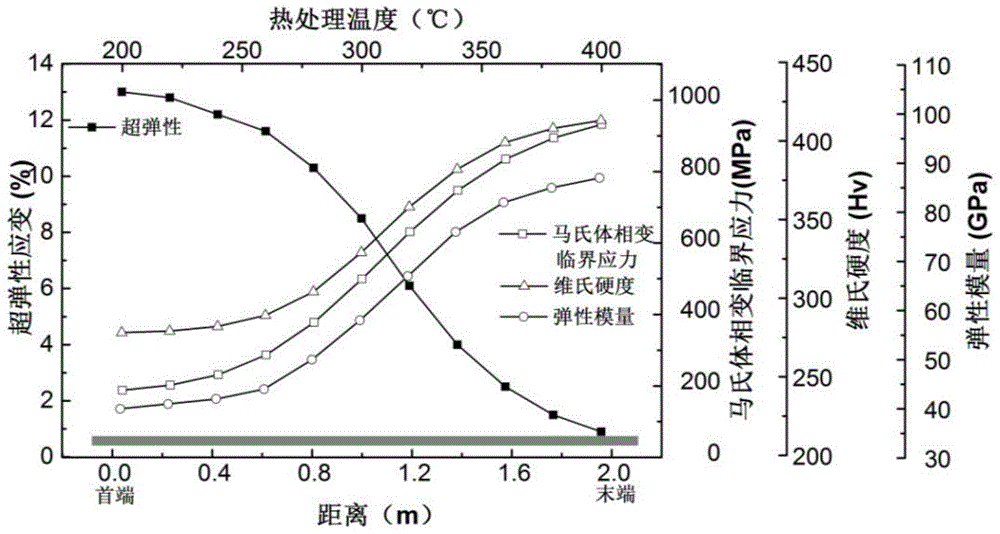

[0044] Preparation of gradient functional guide wires

[0045] Adopt the continuous directional solidification method, use the pull-down continuous directional solidification equipment, use oxygen-free copper, electrolytic aluminum and electrolytic manganese with a purity of 99.95% as raw materials, according to the chemical formula Cu 71.5 al 17 mn 11.5 Proportioning, through mixing, vacuum smelting and down-drawing, etc., a smooth columnar crystal structure Cu with a diameter of 4mm is prepared. 71.5 al 17 mn 11.5 For the alloy wire rod, the vacuum melting temperature is 1200°C, the temperature of the graphite casting mold is controlled to be 1100°C, and the casting speed is 20mm / min. The columnar grain structure Cu prepared by measuring 71.5 al 17 mn 11.5 The starting temperature of the martensitic transformation of the alloy wire is -24.1°C, its superelasticity is 13.1% at room temperature, the Vickers hardness is 256Hv, and the critical stress of the martensitic tr...

Embodiment 2

[0052] Fabrication of Rods for Functional Gradient Robotic Arms

[0053] Adopt the continuous directional solidification method, use the pull-down continuous directional solidification equipment, use oxygen-free copper, electrolytic aluminum and electrolytic manganese with a purity of 99.95% as raw materials, according to the chemical formula Cu 71 al 19 mn 10 Proportioning, and then through the processes of mixing, vacuum smelting and down drawing, a columnar crystal structure Cu with a diameter of 10mm is prepared. 71 al 19 mn 10 Alloy rods, wherein the vacuum melting temperature is 1150°C, the casting mold temperature is 1050°C, and the casting speed is 10mm / min; the columnar grain structure Cu 71 al 19 mn 10 The starting temperature of the martensitic transformation of the alloy billet is -43.2°C, its superelasticity is 13% at room temperature, the Vickers hardness is 266Hv, and the critical stress of the martensitic transformation is 278MPa.

[0054] The gradient h...

Embodiment 3

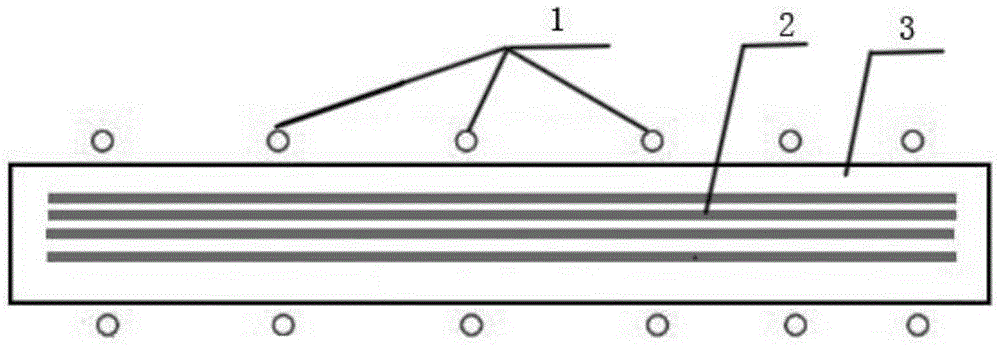

[0060] Fabrication of Functionally Gradient Foldable Electronic Device Panels

[0061] Using the directional solidification method, using oxygen-free copper, electrolytic aluminum and electrolytic manganese with a purity of 99.95% as raw materials, according to the chemical formula Cu 70 al 20 mn 10 Proportioning, and then through smelting (melting temperature is 1200°C) and directional solidification (the graphite mold is heated in the circumferential direction, the temperature is 1100°C; the base of the water-cooled copper mold is cooled), and the columnar crystal structure Cu with a size of 150mm×80mm×50mm is prepared. 70 al 20 mn 10 (at.%) cast slab, measured the columnar grain structure Cu 70 al 20 mn 10 (at.%) The starting temperature of the martensitic transformation of the slab is -61.2°C, the superelasticity is 15% at room temperature, the Vickers hardness is 230Hv, the critical stress of the martensitic transformation is 192MPa, and the wire cutting is 150mm×80...

PUM

| Property | Measurement | Unit |

|---|---|---|

| hardness | aaaaa | aaaaa |

| tensile strength | aaaaa | aaaaa |

| hardness | aaaaa | aaaaa |

Abstract

Description

Claims

Application Information

Login to View More

Login to View More - R&D

- Intellectual Property

- Life Sciences

- Materials

- Tech Scout

- Unparalleled Data Quality

- Higher Quality Content

- 60% Fewer Hallucinations

Browse by: Latest US Patents, China's latest patents, Technical Efficacy Thesaurus, Application Domain, Technology Topic, Popular Technical Reports.

© 2025 PatSnap. All rights reserved.Legal|Privacy policy|Modern Slavery Act Transparency Statement|Sitemap|About US| Contact US: help@patsnap.com