Soft burster block and manufacturing method thereof

A bulletproof plate, soft technology, applied in the structure, fabric, textile and other directions of the armor plate, can solve the problems of inability to bend and high hardness, and achieve the effect of enhancing the softness, suitable for disassembly and assembly, and reducing health damage.

- Summary

- Abstract

- Description

- Claims

- Application Information

AI Technical Summary

Problems solved by technology

Method used

Image

Examples

Embodiment Construction

[0025] Preferred embodiments of the present invention will be described in detail below in conjunction with the accompanying drawings.

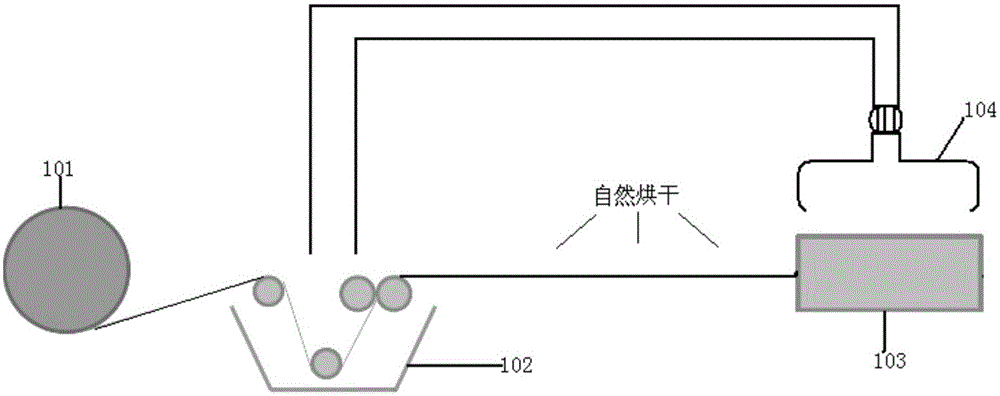

[0026] refer to Figure 1 to Figure 2 As shown, a soft bulletproof board, the bulletproof board is made of non-weft or woven fabric made of high-performance fiber fabrics such as aramid fiber, high-performance polyethylene fiber, carbon fiber, etc., and rubber, polyurethane Made of elastic body;

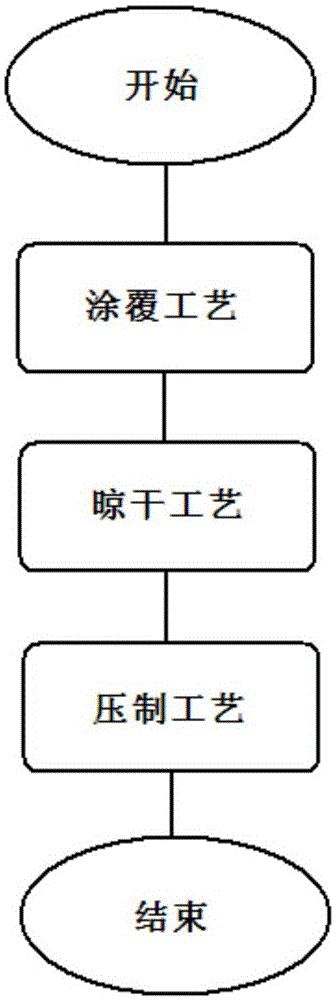

[0027] A method for manufacturing a soft bulletproof plate, comprising: a coating process, a drying process, and a pressing process;

[0028] In order to better describe the production method, the preferred implementation examples are as follows, specifically:

[0029] ① Coating process: use elastomers such as rubber or polyurethane as the substrate, and coat them on high-performance fiber fabrics;

[0030] As an example, the high-performance fiber fabric is selected from fabrics woven with high-performance fibers such as aramid fiber, ultra-high...

PUM

Login to View More

Login to View More Abstract

Description

Claims

Application Information

Login to View More

Login to View More - R&D

- Intellectual Property

- Life Sciences

- Materials

- Tech Scout

- Unparalleled Data Quality

- Higher Quality Content

- 60% Fewer Hallucinations

Browse by: Latest US Patents, China's latest patents, Technical Efficacy Thesaurus, Application Domain, Technology Topic, Popular Technical Reports.

© 2025 PatSnap. All rights reserved.Legal|Privacy policy|Modern Slavery Act Transparency Statement|Sitemap|About US| Contact US: help@patsnap.com