Compound polyimide retainer storage life prediction method

A composite polyimide, storage life technology, applied in the direction of applying stable tension/pressure to test material strength, mechanical bearing testing, special data processing applications, etc., can solve problems such as gaps and different structures, and achieve small physical strength, The effect of short test period and high prediction accuracy

- Summary

- Abstract

- Description

- Claims

- Application Information

AI Technical Summary

Problems solved by technology

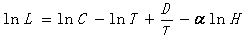

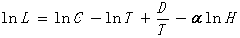

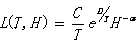

Method used

Image

Examples

Embodiment 1

[0039]A method for predicting the storage life of a composite polyimide cage, comprising the following steps:

[0040] The first step: Determine the aging mechanism of the composite homoanhydride polyimide cage that needs to predict the storage life, as follows:

[0041] Put two groups of samples of composite homoanhydride type polyimide cages with the same quantity into a humid heat aging box with a temperature of 90°C and a humidity of 90%RH and a high-temperature aging box with a temperature of 90°C, every 10 days , take out 5 (or 3 or 4) samples for tensile strength test;

[0042] After testing for 5000 hours respectively, the tensile strength of the composite homoanhydride type polyimide cage in the humid heat aging box dropped from 85MPa to 55MPa, and the drop rate reached 35%, exceeding 30%. The tensile strength of the composite homoanhydride type polyimide cage does not change, that is, the performance decline rate is zero, so it is judged that the aging mechanism of ...

Embodiment 2

[0065] A method for predicting the storage life of a composite polyimide cage, comprising the following steps:

[0066] The first step: determine the aging mechanism of the composite ether anhydride polyimide cage, as follows:

[0067] Put the same or different two groups of the same composite ether anhydride type polyimide cage samples into the 90°C, 90%RH humidity heat aging box and the 90°C high temperature aging box, and take them out every 30 days. 5 (or 3 or 4) specimens are tested for tensile strength.

[0068] After the two groups of samples were tested for 5000 hours, the tensile strength of the two groups of samples did not change significantly. Therefore, it is judged that the aging mechanism of the composite ether anhydride type polyimide cage is thermo-oxidative aging.

[0069] It is also possible to further use Fourier transform infrared to analyze the internal structure of the material. It was found that the characteristic peaks of the new substances generate...

PUM

| Property | Measurement | Unit |

|---|---|---|

| tensile strength | aaaaa | aaaaa |

| tensile strength | aaaaa | aaaaa |

| tensile strength | aaaaa | aaaaa |

Abstract

Description

Claims

Application Information

Login to View More

Login to View More - R&D

- Intellectual Property

- Life Sciences

- Materials

- Tech Scout

- Unparalleled Data Quality

- Higher Quality Content

- 60% Fewer Hallucinations

Browse by: Latest US Patents, China's latest patents, Technical Efficacy Thesaurus, Application Domain, Technology Topic, Popular Technical Reports.

© 2025 PatSnap. All rights reserved.Legal|Privacy policy|Modern Slavery Act Transparency Statement|Sitemap|About US| Contact US: help@patsnap.com